Non Ferrous Melting Furnaces

Top Manufacturer in China

- With the power is 3.5-160kw optional

- With the capacity of 1-250kg gold/silver/platinum

- Adopt IGBT induction heating technology

- 15-30% energy than KGPS, 100% full load

Apply Our Best Quotation

Top Non Ferrous Melting Furnaces

Superbmelt non-ferrous metal melting furnace is used to melt between 1g to 250kg of metals. Metals such as gold, silver, copper, stainless steel, platinum, palladium, etc can be melted efficiently with a Superbmelt induction furnace.

Superbmelt crucible melting furnace makes use of an IGBT induction heating technology that ensures melting speed, quality and reduces energy use. The maximum melting temperature is between 1600 to 2800 degrees celsius. The non-ferrous metal melting furnace is applicable for use in jewellery production, steel production, scrap recycling, etc.

Superbmelt has various induction melting pots you can choose from to meet your specific melting needs.

Superbmelt Non Ferrous Melting Furnaces list

The mini melting machine is used to melt up to 2kg of precious metals in 2 minutes. It is suitable for melting silver, copper, gold, bronze, etc. The portable melting furnace has a melting temperature of 1600 degrees celsius with a power requirement of 3.8kw. The mini melting furnace is compact in size, easy to transport and lasts long.

Parameter

- Capacity: 1-2kg

- Power: 2.5kw/3.8kw

- Application: gold, silver, copper, iron etc.

The integrated melting furnace is a compact size furnace that is able to melt up to 6kg of metals in 4 minutes. The furnace melts metals such as gold, silver, copper, etc at a melting temperature of 1800 degrees celsius. The furnace is designed with wheels that make it easy to transport. The power required for melting is between 15kw and 25kw.

Parameter

- Capacity: 3-5kg

- Power: 15kw/25kw

- Application: gold, silver, copper, iron etc.

The manual tilting furnace is used for melting ferrous and non-ferrous metals measuring up to 12kg. The melting process is fast and efficient with a melting time of 5 minutes. The manual furnace is designed with a tilting device that makes the process of molten metal removal easy. The maximum melting temperature is 2800 degrees celsius suitable for platinum and palladium.

Parameter

- Capacity: Max. 10kg

- Power: 15kw

- Application: gold, silver, copper, iron etc.

The split furnace is used for melting metals measuring up to 30kg. The maximum power required for melting is 35kw. The induction heating technology ensures that melting is complete within 8 minutes. It melts at a maximum temperature of 1800 degrees celsius. The furnace has a PLC control unit and a tilting device that makes it easy to use in large applications.

Parameter

- Capacity: 20-30kg

- Power: 25kw/35kw

- Application: gold, silver, copper, iron etc.

The chain tilting furnace is an industrial size melting furnace suitable for melting 50kg of precious metals and base metals. The maximum power required for melting is 45kw. The IGBT induction technology helps to conserve energy use and increase melting speed. It is suitable for melting gold, copper, iron, etc. The furnace is designed with a user-friendly interface.

Parameter

- Capacity: 10-50kg

- Power: 15kw/45kw

- Application: gold, silver, copper, iron etc.

The motor tilting furnace is used for commercial melting applications. The motor melting furnace melts up to 100kg of ferrous and non-ferrous metals. The machine is designed for easy transport and easy removal of molten metal. The furnace is easy to use due to the PLC control unit. The power required for melting is 160kw. The induction technology helps the furnace to conserve energy.

Parameter

- Capacity: 10-100kg

- Power: 15kw/160kw

- Application: gold, silver, copper, iron etc.

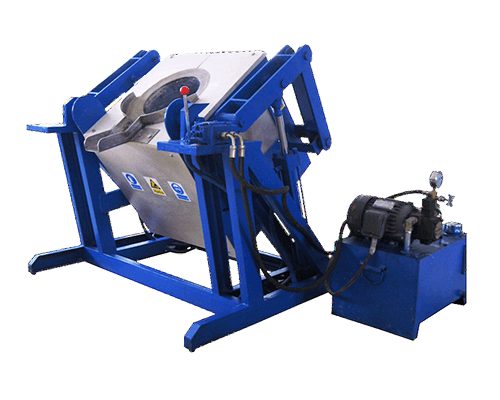

The hydraulic furnace is used to melt metals such as gold, silver, copper, steel of 250kg, The maximum power required for melting is 160kw. The induction heating technology ensures melting is fast and efficient for large scale melting needs. The electromagnetic stirring function homogeneously mixes the molten metal for high-quality casting.

Parameter

- Capacity: 50-250kg

- Power: 15kw/160kw

- Application: gold, silver, copper, iron etc.

Why You Could Choose Superbmelt

2 years warranty

The warranty for our machine is one year longer than the warranty provided by other factories.

ISO CE SGS approved

Professional certification bodies certify that the machines are of high quality.

Strong service team

We will give response within 24 hours against your problem by our professional engineer.

FAQ Guide of Non Ferrous Melting Furnaces

- 1.How fast can gold melt?

- 2.What temperature can the induction non ferrous melting furnaces reach?

- 3.How does an induction metal melting pot work?

- 4.How to choose the right non ferrous melting furnace?

- 5.Can you melt down different karats of gold together?

- 6.Can you melt down gold to make jewelry?

- 7.How efficient is induction heating?

- 8.How many ways does gold smelt?

- 9.How much gold is lost when melted?

- 10.Can you melt down gold to make jewelry?

- 11.How do you melt gold rings?

- 12.How efficient is induction heating?

- 13.What are the advantages of electric heating?

- 14.What can you use as a crucible?

- 15.How metal melting pot for gold mining?

- 16.How metal melting pot for precious metals DIY enthusiasts?

- 17.How metal melting pot for gold mining laboratories?

- 18.Can you melt old gold rings to make new ones?

- 19.Does this machine need a water chiller?

- 20.How do you get impurities out of gold?

1. How fast can gold melt?

Metals tend to have a high melting point. Since gold is a metallic element, it is one of the best conductors of heat and electricity. The standard melting point of gold is 1064 degrees Celsius, or 1,943 degrees Fahrenheit.

It is considered to be one of the highest melting points of metal. This is due to gold’s resistance to heat along with its conductivity. If the melting point of gold starts at 1,064 degrees Celsius, then it’s considered pure gold. Due to such a high temperature, it might take quite a while to melt gold in the standard process.

However, with the use of the latest technologies non ferrous melting furnaces have been manufactured that provides extreme speed with melting metals. These furnaces take about 2 minutes to melt gold, silver, platinum, and many other precious metals. The electric non ferrous melting furnaces have significantly increased the efficiency of production for jewelry makers. The features of identifying impurities of these metals also come in handy for jewelers.

2. What temperature can the induction non ferrous melting furnaces reach?

Induction metal melting pots comes with a wide variety of equipment services that enables many industries to process metals from melting. These machines can offer services such as casting, heating, rolling, drawing, forming, and shaping the metal to produce the final product.

An induction non ferrous melting furnace does not generally have any temperature limit to melt or heat. But the refractories and containers that hold heated or melted metallic products possess heat limitations.

Electric non ferrous melting furnaces can reach the highest temperature up to 3300 degrees Fahrenheit in the open air. However, in constricted atmospheres, these machines can reach excess temperatures up to 5000 degrees Fahrenheit.

However, the temperature might vary according to metal choices. Due to its extreme temperature limits, jewelers find a metal melting pot for sale quite suitable to melt precious metals. From heating platinum group to graphite, all metals can be melted within minutes in the machines, rather than taking hours like the standard procedure.

3. How does an induction metal melting pot work?

The induction metal melting procedure is a non-contact heating form for melting conductive materials. The machine works on the principle of electromagnetic induction and the joules effect.

The gold and copper melting pot induction furnace utilizes coil heating elements used within a crucible or merged into the walls of the machine’s heating chamber to produce a magnetic field. Such principle results in converting electrical energy into heat, which radiates through the materials to provide an extreme degree of thermal uniformity.

As the heat gets transferred to the melting product via electromagnetic waves, the users would not come in direct contact with the flame, so there would not be any product contaminates during the process. The electromagnetic field can change its direction depending on which direction the current is flowing.

Due to such principles, the smelting pot for gold provides a rapid, clean, and non-polluting heating system to melt precious metals. The electronic non ferrous melting furnaces provide the advantage of a clean, energy-efficient, and well controllable melting process in comparison to the conventional method for both small and large-scale industrial use.

4. How to choose the right non ferrous melting furnace?

In order to look for a nonferrous non ferrous melting furnace, you must be aware of the ferrous and nonferrous metals. Generally, those materials that do not contain iron are known as nonferrous metals, while iron-containing materials have iron. Mostly, precious metals such as gold, silver, and platinum are nonferrous.

Moreover, other nonferrous metals that can be melted in a steel melting pot are copper, bronze, brass, nickel, palladium, titanium, aluminum, Tin, etc. So make sure all these aforementioned metals can be melted in the machine. Another factor to consider is knowing the melting points of the metals.

If you have a specific requirement for melting certain metals, then it’s better to choose an electronic metal smelting pot that can produce such temperature to melt them effectively. Check for the melting capacity of the machine, which is its size. Consider the price of the machine that is determined by its size, model, and purpose of the furnace.

5. Can you melt down different karats of gold together?

Yes, you can melt different karats of gold together. Melting different karats of gold is how professionals solder or weld two pieces of gold together. With a high Karat gold, there is a lower carat gold added as it melts a bit faster to bind the gold pieces together.

Since Karat is just a measuring unit for specifying the total percentage of pure gold present in the solid piece of gold item, it doesn’t affect the quality of gold. But if they are two different colors of gold, they need to be cast separately, so the melting would not affect the aesthetical appearance of the gold after smelting.

However, mixing different karats of gold in the electronic smelting pot for gold would result in producing an alloy with an add karat. Jewelry manufacturers who use electronic gold, silver, and aluminum melting pot, have to mark the item with a lower carat when they need to stamp it.

6. Can you melt down gold to make jewelry?

Most people give out their old jewelry to produce a new one from them. Thus, you can melt down your old jewelry to use that gold to make a new piece. It’s a great idea to keep up with its originality and if it holds sentimental value.

More than rose gold or white gold, it’s easier to reuse yellow gold since they are generally produced with fewer impurities. While you can mix different melt carats of gold, you should melt down different colors of gold separately to produce new jewelry.

You can invest in the electronic gold and copper melting pot to make the melting process faster and energy-efficient. There is much other equipment that can be used with the induction gold and brass melting pot to achieve many other services such as casting, heating, rolling, drawing, forming, and shaping the melted material into fine products and produce unique jewelry efficiently.

7. How efficient is induction heating?

Induction heating technologies offers minimal wasting of heat energy as it directly transfers it to the heated part to produce efficient results and significantly saving power. Therefore, the non ferrous melting furnace uses an induction heating process to melt precious metals.

As the induction metal melting principles are highly efficient for various industrial metal heating applications, the gold and steel melting pot are getting more in demand in the commercial sectors.

In comparison to torch or oven heating, induction metal heating and melting offer a myriad of benefits, e.g., induction transfers that provide more power to support the loading capacity, no heat is released to heat up the working environment that can result in energy wastage and there would not be any ramp up, etc. The induction heating process is a more productive principle to utilize as it delivers power when required in a clean-cut process.

8. How many ways does gold smelt?

Generally, melting and smelting are two terms used frequently when it comes to converting a solid item into liquid. While melting methods are applied to melt the gold at its melting point, the smelting process is achieved by applying temperatures beyond the gold’s melting point on the ore to convert it into its purest form.

The standard melting point of gold is already high enough, i.e., 1064 degrees celsius. Thus most industrial users utilize electronic non ferrous melting furnace to maximize their productivity. There are many ways to smelt gold in the standard process, e.g., using a propane torch, electric gold melting pot furnace, microwave oven, using resistance furnace, etc.

You can put the gold item in a crucible and place it on a fire-resistant surface, then light a propane torch to witness the gold smelt within minutes. Gold induction melting furnaces can be used in both high and low production levels. The device has the capacity of producing a high level of temperature, so it’s suitable for carrying out the smelting process to give the final product faster.

9. How much gold is lost when melted?

The fineness of gold does not get affected with melted. However, gold would be lost while melting if there are any small beads of molten Karat hung up in the slag. Other than that, the gold loss can come with sawing and filing the gold object. And the loose percentage can fall between 0.8 to 1.2%.

However, the rate can vary from one job to another. Therefore, there would not be much gold loss while melting. From general studies, gold losses from refining are about 1%-2.5% due to mass loss, while 1.5%-2.5% are due to assay or undercarat losses. Thus, professional jewelers and retailers use non ferrous melting furnace to prevent the loss of gold value.

Such an electric gold melting pot uses advanced technologies that can effectively evaluate the pure gold amount and detect the presence of impurities while the gold melting procedure takes place. Almost all kinds of gold items such as jewelry, coins, and bars can be melted with these machines.

10. Can you melt down gold to make jewelry?

Yes, you can melt down gold to manufacture new jewelry. But the traditional methods can take so much of your time to prepare a piece of jewelry. So why not invest in buying an electronic metal melting pot for sale to melt the metal, cast, and shape the material to produce the jewelry in the safest way.

But when it comes to making a new piece of jewelry out of old ones, it’s not wise to melt them down to make new pieces. When you melt down the old jewelry, it makes the metal weaker, and its quality becomes poorer than the fresh metal due to the presence of impurities and alloy.

However, you can use electric gold and copper melting pot to extract the metal in the smelting process to get its purest form and add other required precious metals to strengthen its form jewelry out of it. Jewelers use this process to produce jewelry pieces from client’s old jewelry.

11. How do you melt gold rings?

In the traditional process, the rings are placed in a crucible and heated up to 1100 degrees Celsius. As the gold starts to melt, keep heating it to turn it into its molten state until the material starts to flow together as one mass.

Then pour the molten gold into a casting mold to produce an ingot. Afterward, let it cool down. Once the metal is cooled, the ingot passed through a series of rolling mills to turn it into a wire. Then the goldsmith can give it shapes to produce new rings. With an electronic smelting pot for gold, you can conduct all the aforementioned processes.

The gold ring production process would not only be a lot easier, but it would also be a lot faster. Industrial operators use gold and silver melting pot furnaces along with various other equipment to effectively produce jewelry more efficient and environmentally friendly.

12. How efficient is induction heating?

The induction heating process is considered very effective when it comes to melting gold and other precious metals. The induction heating system offers the advantage of localized, consistent, and precise heating. This technology also allows the electronic gold and aluminum melting pot to control the temperature according to the requirement.

This feature benefits the user to save energy. Induction heating can provide many possibilities of integration into the jewelry production lines. The best quality non ferrous melting furnaces with an induction heating process can yield quality performance in jewelry production.

The induction heating process’s prominent feature is that it does not produce any kind of waste, making it a pollution-free, environmentally friendly solution for melting precious metals, which is quite faster than the traditional melting methods. Due to the use of secure technology, the smelting pot for silver and gold machines is getting more preferable for many industrial applications.

13. What are the advantages of electric heating?

Electric heating has more advantages over any other type of heating method. Using an electric non ferrous melting furnace, the operator can get the benefit of uniform stirring of charge, which would offer homogenous molten metal composition. Heating any of the precious metal in the electric heating furnace would help the user to save energy at a rate between 15% to 30%.

The implementation of the latest technologies allows the operator to easily monitor the heating temperature and melting level without requiring to opening up the furnace frequently. Moreover, the melting speed rate is faster than other melting processes; the electric heating process is also time-efficient.

All the equipment used in the electric gold and brass melting pot for the smelting process doesn’t release harmful gases to the outer environment and doesn’t make any noise as well. It helps you achieve a clean melting operation as the machine also has a water cooling unit that allows the equipment to function continuously for long hours.

This electric non ferrous melting furnaces can also be easily charged, metal pouring & the temperature can be controlled effortlessly.

14. What can you use as a crucible?

Crucibles used for melting metal should have a higher melting point than the metal they are to hold. So choosing the material of the crucible is essential while purchasing electric gold and brass melting pot.

Carbon-bonded and ceramic-bonded clay, graphite, and silicon carbide crucibles are extensively used in melting and holding gold and silver along with various other precious metals. Furthermore, crucibles are also used in melting cast iron.

Although crucible types are chosen according to support the metal temperatures, which can entail a broad spectrum of metal types, you should always select a crucible that targets to hold some specific metals or alloys with more limited operating temperature ranges.

Selecting such crucibles are more advantageous as they can offer to perform important characteristics that are required for your operations. It is recommended to use graphite crucibles in your electric non ferrous melting furnace; if you have metals to melt below 1600 degrees Celsius, and metals with a higher melting point than 1600 degrees Celsius, then use a quartz crucible.

15. How metal melting pot for gold mining?

The metal melting pot is abundantly used in the gold mining industry to extract gold from the gold ore. Using the electronic non ferrous melting furnaces for gold is the most effective gold smelting technique to complete the process faster than the conventional methods such as propane torch and resistance furnace etc.

As the non ferrous melting furnaces utilizes an induction heating process, it provides many rare advantages over others. Although it’s an expensive method, these machines can conduct many jewelry-making services in one device and has extreme durability. Since induction heating produces no waste from the smelting process, it is recommended the most.

However, if you don’t have access to an induction metal heating machine, you can always opt for a propane torch as well as a resistance furnace. Since there are a large number of gold ores have to be processed in gold mining, the standard processes can consume a lot of time to extract pure gold. Therefore, an electronic smelting pot for gold is most recommended to achieve faster operation.

16. How metal melting pot for precious metals DIY enthusiasts?

Gold ores contain a lot of impurities, including other metallic and alloy traces, minerals, and debris. Therefore, the gold mining sites use a non ferrous melting furnaces to effectively extract pure gold and separate all the impurities from the primary metal.

Generally, gold is melted in order to produce various types of gold items such as gold jewelry, coins, bars, and many more. People can use various methods to melt gold, i.e., propane torch, gold melting machine, and resistance furnace, etc.

However, the electric gold, silver, and copper melting pot is most recommended due to its faster functionality and use of an induction heating system. This machine can be used for small and large size gold production, so it’s very much suitable for DIY enthusiasts.

The operator just has to heat up the furnace and charge the gold particles in the gold jewelry, let it melt for a few minutes while you monitor the process in the device. Then remove the molten gold from the crucible to cast, roll, and shape it to produce gold items.

17. How metal melting pot for gold mining laboratories?

Gold mining industries use effective gold smelting techniques to extract gold from the ore. The three most used gold smelting methods are abundantly used, i.e., induction heating, propane torch, and resistance furnace.

Since the electronic gold melting pot are suitable for both small and large size gold melting production, the machines can also be used in gold mining laboratories. The device can analyze the impurity level as well as their presence amount in its gold refining process.

Impurities are not just unnecessary minerals; they are also other metals such as copper, zinc, and iron, etc., along with other precious metals. The operator has to use flux to remove impurities through the smelting process. Note that you can’t achieve 99% pure gold only with a smelting pot for gold, so you have to go through the refining process to obtain good quality gold.

18. Can you melt old gold rings to make new ones?

In order to make jewelry, you have to melt down the gold bar or coins. But since gold can get fragile after so much stretching and lengthening to prepare intricate designing in the jewelry piece. Thus, pure gold is mixed with alloys to make the material more durable. Commercial jewelry manufacturers use non ferrous melting furnace for faster and efficient production of gold jewelry pieces.

However, it’s not recommended to melt down old gold rings to craft a new ring since the meltdown weakens the metal, and the quality becomes poorer than the fresh metal. Thus, it’s wise to separate the pure gold from the alloys first via a metal smelting pot before starting a new production process with it.

19. Does this machine need a water chiller?

The induction non ferrous melting furnaces is able to produce an excellent amount of heat energy to raise the temperature, so the metals with high melting points can be melted faster and effectively. However, without the integration of safety technology, the device can get burst.

Thus, the gold and steel melting pot uses an induction heating process as well as water cooling technology, so there would not be any waste of energy, and the temperature can be controlled accordingly.

20. How do you get impurities out of gold?

Typically gold is smelted using borax which is regarded as a flux. The application of flux before starting the heating process enables the impure substances attached to gold to rise to the top surface of the crucible as the heating process commences. The non ferrous melting furnace alone would not be able to achieve 99% pure gold. So, you have to integrate a refining process in the smelting pot for gold to obtain maximum purity.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited