Platinum Casting Machine

Top Technology of Vacuum Pressurized Platinum Casting on the Market

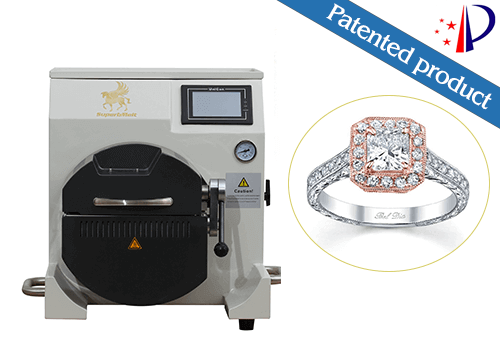

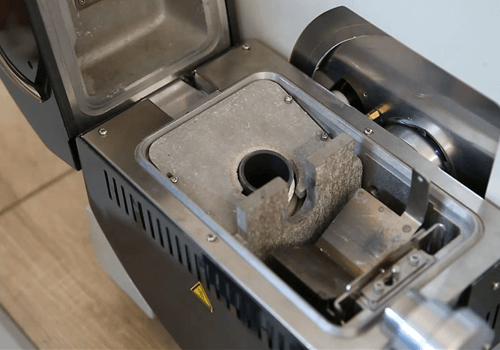

SuperbMelt vacuum platinum casting machine (SPB-MVC150) is a high-quality device primarily designed for melting

and casting metals weighing no more than 300 g platinum (300 g goldor 150 g silver). It can heat up to 2600 °C, so it can be used for the casting of platinum group metals

The SuperbMelt vacuum platinum casting unit (SPB-MVC150) has a gas chamber in it. The gas chamber which releases pressurized inert gases during the casting process which fully removes any sort of porosity and oxidation. This feature that gives your final cast a touch of quality and class.

Manufacturer of a wide range of products including platinum casting machine, Superbmelt is an acclaimed expert in the industry owing to their excellency in producing quality-made products. To add, Superbmelt only utilizes optimum class materials to serve our valued customers the world-class service.

With innovation and forward-thinking, Superbmelt platinum casting machine is able to cast any of your precious metals in the shortest time possible. Also incorporated into the design of this casting machine is a 4.5Kw induction generator. This platinum casting machine is capable of melting any piece of your precious metal or artwork in no less than 3 – 5 minutes. Assembled with a powerful built-in generator, your production process will absolutely speed up in no time coupled in saving in investment from lost hours.

Purposely designed with automatic intelligent control system, the Superbmelt platinum casting machine makes your whole casting process very safe and seamless. During operation, both your melting and casting chambers can be flipped automatically. This exclusive automated feature of platinum casting machine allows you to have less manpower, fewer personnel, fewer labor costs and savings in power utility for your casting operations.

Backed by years of technical experience, we are offering a wide range of exclusive features which are precisely studied under the supervision of the industry experts:

- This fully automated machine requires no crucibles, no flask rings, and for that reason, no flasks with no change to your usual treeing and investing processes.

- Ideal for custom casting, for studio works, and even in minor scale productions, Superbmelt platinum casting machine is equipped with incredible melting capabilities.

- Can easily change from one metal to another by simply adjusting the machine settings — allows you to time-efficient by not changing out consumables or clean and prep the system in any way.

- Offers a full range of casting options for different casting needs—With or without a protective inert argon atmosphere, you can choose to melt your metal in the air or under pressure/vacuum

- Equipped with touch-screen LCD control display to easily adjust control over each cast

- Has a program-saving feature that allows you to save settings for programs you use often

- Precise and accurate temperature readings with our built-in infrared sensor

- The vacuum platinum casting machine automatically stop the machine when an error is detected.

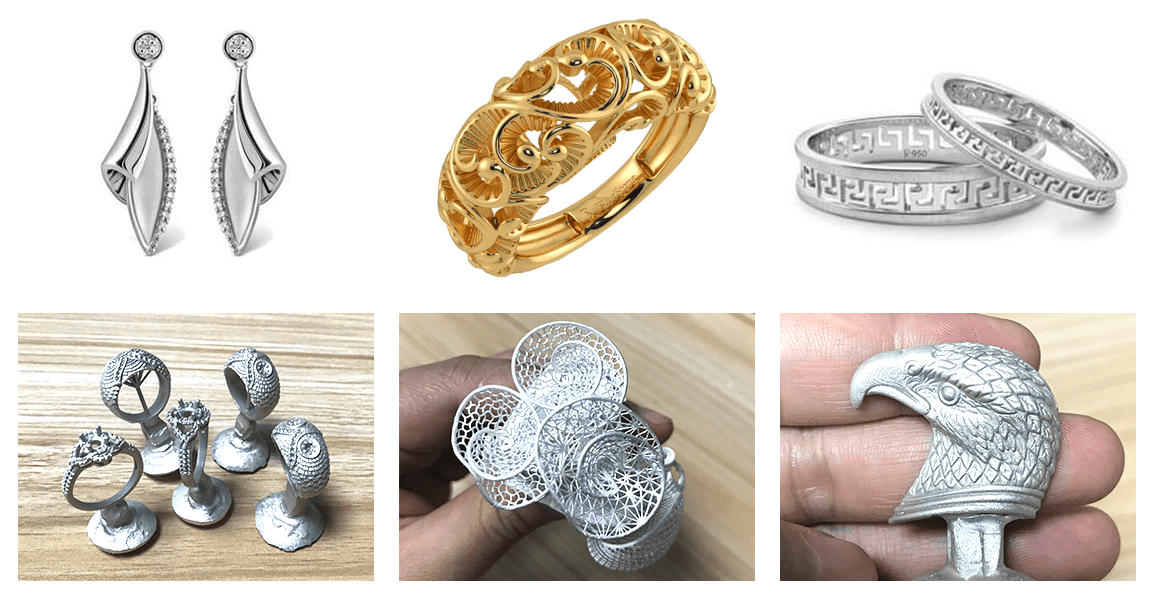

Our clients can avail of a quality-approved platinum casting machine built onto a specially designed rubber base, that accommodates a wide selection of jewelry styles. Once invested, this machine easily handles most-jewelry making metals, including white metals. However experienced you are, or even without any prior technical knowledge of casting, this platinum casting machine simply eliminates all your worries of porosity or shrinkage and metal contamination.

If you want a simple, quick and safe, with an impeccable appearance and a touch of class, the features of this platinum casting machine is one of the best you will ever find in the market. To know more, get in touch with us through our con contact details. Our team of technical specialists will be happy to assist you!

Mini jewelry casting machine parameter

| Model | SPB-MVC150 |

| Power Requirement | 220V |

| Power Consumption | 4.5kw |

| Maximum Temperature | 2600 ℃ |

| Melting Method | Induction Heating |

| Capacity | 300g platinum (300g gold or 150g silver) |

| Application | Platinum, palladium, gold, silver, steel, copper |

| Control System | PLC |

| Melting Time | 5-6mins |

| Gas Pressure | Max. 3.5 MPa |

| Pressurized Atmosphere | Argon |

| Ultimate vacuum | -0.1 MPa |

| Type of Crucibles | Quartz crucible |

| Cooling System | Water cooling |

| vacuum pump | built-in |

| automatic vacuum function | Y |

| Flip function | Automatic flip and vacuum casting |

Mini vacuum investment powder mixer parameter

| Model | SPB-MIPM1 |

| Power source | 220V |

| Power | 350w |

| Dimension | 540*510*390mm |

| Weight | 18kg |

Mini wax burnout furnace parameter

| Model | SPB-MWF1 |

| Power source | 220V |

| Power | 5kw |

| Chamber size | 300*200*120mm |

| Max Temperature | 1200 ℃ |

| Weight | 60kg |

2 years warranty

The warranty for our machine is one year longer than the warranty provided by other factories.

Strong service team

We will give response within 24 hours against your problem by our professional engineer.

Why SuperbMelt Platinum Casting Machine

More SuperbMelt Precious Metals Casting Machines For Your Choice

Any Question About SuperbMelt Vacuum Platinum Casting Machine

How to Cast Platinum (Platinum Casting Process) and Platinum Casting Equipment Buying Guide

Platinum boasts an exciting history. In Egypt, between 1200-700BC small quantities of Platinum were used alongside Gold to create decorative objects. La Tolita Indians bordered a rich source of platinum; between Colombia and Ecuador. They used platinum to make earrings, nose rings, and masks. Though these kinds of uses were isolated, they have been carefully documented by scholars and researchers. Platinum has been used for luxury reasons for thousands of years.

Platinum bears unique characteristics that make it an ideal metal for fashioning jewelry. This also explains why it has evolved slowly but steadily over time. This luxurious metal has a melting point of 3221.6 degrees. It is very strong and highly durable, which means you can’t change its shape and form before softening it.

Until the 19th century, no one had a clue of how to make platinum malleable. Early Egyptians and Indians used techniques that were lost somewhere in history. The same happened to its sources. The modern discovery of platinum dates back to late 1600s. During this time, it was used, but people believed it to be an unusable immature type of Gold. At this time, platinum remained obscure since its value was still not known.

Introduction of Platinum

Platinum has been used for at least three centuries now. This means that the mining started in the 1600s. It is imperative to note that the ancient methods of platinum mining were quite primitive. In this section, we intend to look at both ancient and modern platinum mining methods to help you understand how technological advancement took effect in this regard.

1.1, What are the Characteristics of Platinum?

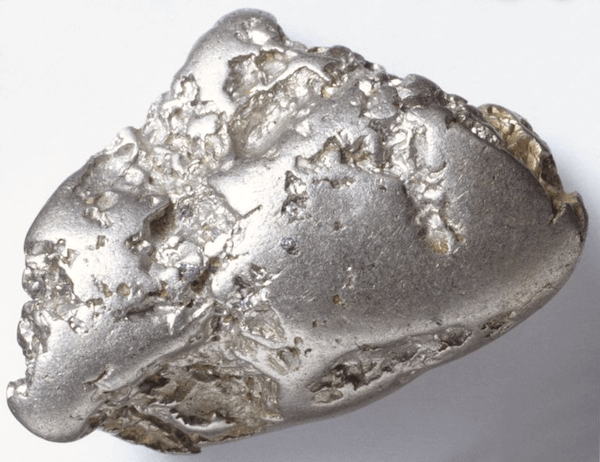

In the 16th century, platinum was thought to be platina or rather little silver. In the 18th century, it was termed as the only best metal for a king. Let us take at some striking characteristics of platinum.

The element has a chemical symbol Pt and is a silvery-gray metal. It is one of the only six metals that feature platinum group metals. There are other platinum group metals (PGMs) such as osmium (Os), iridium (Ir), ruthenium (Ru), rhodium (Rh), and palladium (Pd). Albeit platinum is rare, it is the most common of all the PGMs.

In the jewelry industry, platinum is used alloyed with other PGMs. Compared to pure platinum, platinum alloys weigh less, but they are harder than the pure one.

When a measurement is taken in parts per billion of the earth’s crust, platinum is more common than gold. However, it tends to be more dispersed and harder to refine. This makes it have a higher price. Platinum also occurs in meteors and asteroids alongside other metals such as titanium, cobalt, and nickel.

Due to the terrestrial quantities of platinum group metals, researchers are now strongly considering asteroid mining. Platinum is one of the heaviest metals on earth. 15 cm of the metal weighs around 75 kg (165 pounds); the same weight as an average adult male. Platinum is also easily malleable and ductile, although less compared to gold. Out of the three most common metals, platinum has the least metal memory. This makes it one of the best substances for making jewelry.

Once platinum is bent, it retains that shape until it is bent into another shape and form again. Since it is quite dense, which makes it add strength to delicate designs of jewelry? Platinum is also highly durable.

When the substance is scratched, it just gets displaced instead of breaking or getting chipped. This makes it easier to repolish without losing its original weight. It has a high resistance to corrosion, and will never react with water, air, heat, or any other chemicals.

1.2, What are the Platinum Application

Platinum is an essential industrial metal. It is used in a wide range of industries where it plays a central role. It is mostly used as a military resource due to its unique properties. The overall demand for platinum falls under at least eight broad categories.

- Jewelry – best substitute for silver and gold

- Automotive- in catalytic converters, sensors, and spark plugs

- Chemical processing- used as a general catalyst

- Petroleum refining- used as a catalyst in cracking crude oil

- Medical/dental – reconstructive and equipment

- Glass- dies and process technology

- Investment – coins and bullions

Platinum has gained popularity in a wide range of industries due to its authentic properties. Some industries use it because of its unique appearance, durability, malleability, ductility, and due to the fact that it is less reactive.

1.3, The History of Platinum Jewelry

Platinum boasts an exciting history. In Egypt, between 1200-700BC small quantities of Platinum were used alongside Gold to create decorative objects. La Tolita Indians bordered a rich source of platinum; between Colombia and Ecuador. They used platinum to make earrings, nose rings, and masks.

Though these kinds of uses were isolated, they have been carefully documented by scholars and researchers. Platinum has been used for luxury reasons for thousands of years.

Platinum bears unique characteristics that make it an ideal metal for fashioning jewelry. This also explains why it has evolved slowly but steadily over time. This luxurious metal has a melting point of 3221.6 degrees. It is very strong and highly durable, which means you can’t change its shape and form before softening it.

Until the 19th century, no one had a clue of how to make platinum malleable. Early Egyptians and Indians used techniques that were lost somewhere in history. The same happened to its sources. The modern discovery of platinum dates back to late 1600s. During this time, it was used, but people believed it to be an unusable immature type of Gold. At this time, platinum remained obscure since its value was still not known.

Platinum found its way to the European scientific community in 1741. It happened that William Browningg, an English man who was a physician and a scientist starting experimenting with samples he received from his brother-in-law. A native Colombian Platinum was used in the experiment. Throughout the 1700s, chemists worked tirelessly, trying to find the best ways to melt and refine platinum.

In 1800 it was found that arsenic and platinum powders fused when mixed. Things become better when it was later discovered that platinum could be melt with the help of flame that has hydrogen and oxygen. Later on, a blowpipe was invented using the gases to help melt the substance. Since the methods were dangerous, the mainstream workshops were loath to adopt them.

For more than three thousand years, platinum has been used to make important items. In ancient times, the jewelries were used to symbolize power, wealth, and luxury. Today, the jewelries made with platinum are mostly used to show a luxurious lifestyle. But this is not 100% the case as there are many other things that could be made out of platinum. The ancient Egyptians and Indians used the substance to make masks, earrings, and nose rings. We intend to delve deeper into this as we discover more about the substance.

What Casting Method Should I use?

Many casting methods can be applied to platinum. However, you need to choose wisely, depending on your budget and the amount of platinum you have. In this section, we have mentioned some of the best casting methods you can choose to apply.

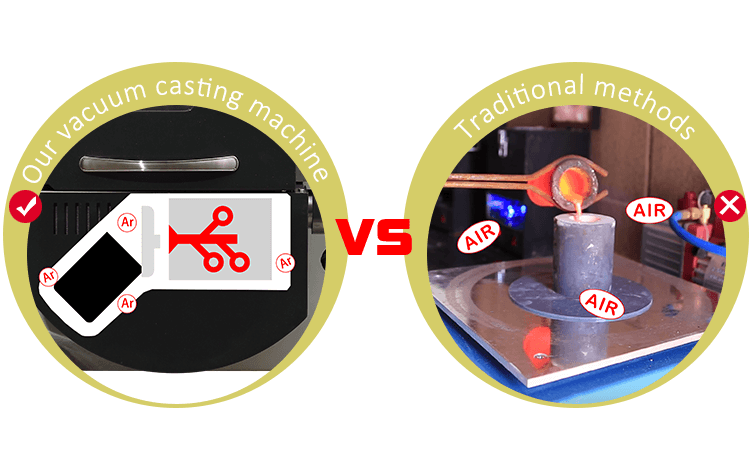

2.1, Vacuum Pressurized Casting

Superbmelt Machines are the most suitable for melting and casting metals of very high melting temperatures, such as platinum. As per their model and design, they have the capacity to melt steel. They can also work on metals or alloys of very low melting points such as aluminum. This means that they come in handy for melting and casting a wide range of substances.

2.2, Centrifugal Casting

If you need to use centrifugal method to cast platinum, then it ought to leverage a temperature of at least 1800 degrees. This is the required maximum temperature to melt and cast platinum. It might feature a gas argon atmosphere and a vacuum pump, but there are optional. However, they come in handy when you need to protect the substance from oxidation. If possible, it should come with an IR temperature reader to help you determine whether the right temperature has been arrived at.

2.3, Other traditional casting methods

If you have a company that casts platinum, you might want to apply the best method that would give you the most impressive results. We have seen that you can either use Vacuum Pressurized Casting or centrifugal casting. However, according to our fifteen-year experience in casting elements, we have used both methods, and we are here to share the reason we feel that Vacuum.

2.4, Pressurized Casting should be your number one choice

First of all, you are supposed to consider the speed at which the two methods work. Without being bias in any way, Vacuum Pressurized Casting beats centrifugal casting with a landslide. It is also economically feasible being that it works pretty fast, and there is not a lot of learning curve involved. Note that with Vacuum Pressurized Casting, you will not be using some traditional method that would reduce the quality that you get from your work as a mineral-oriented company.

2.5, Other traditional casting methods

Pressurized casting is a process that features that se of a compressor and a pressure chamber to get rid of bubbles from the casting out from a casting resin or the mold rubber. The pressure casting technique is mostly used by expert prototype model makers who don’t want to see even a single bubble, but that is how it ought to be. A single bubble located on the surfaces of the casting might cause the entire casting to be discarded.

I. How Does Pressure Casting Work?

- A liquid plastic is mixed and then poured into the rubber mold

- The whole mold structure is put into a pressure chamber

- The lid or door to the pressure chamber gets closed and then secured tightly to prevent air from moving in.

- The pressure will then be turned on, and the resin and mold are subjected to up to 60 psi pressure until the resin gels up..

- The bubbles are then collapsed into the solution, and you will get a bubble-free casting

II. Can I make the Mold under Pressure?

If you intend to use a rubber mold regularly in the casting process, it would be best if you made the rubber mold under high pressure as well. This implies that you will mix and pour the mol rubber over the initial model, putting the structure inside your pressure chamber and then applying a pressure of up to 60 psi until the mold cures.

III. The Reason for Doing This

If you are pressure casting resin in the rubber mold that has not been subjected under pressure, in case of any bubbles in the rubber mold, they might implode under pressure, and then the collapsed bubbles might get reflected in the finished casting. They will show as dimples or bubble positives.

IV. What to Note

Once you have started making a mold of a hollow model and you intend to do it under pressure, it might end up collapsing under pressure.

It is advisable to only use commercial pressure chambers. Many resin casters have learned the hard way that most home-made pressure chambers might end up exploding violently hence causing serious injuries.

It is important to ensure that the running air from the compressor is kept dry. This is mainly used for pressurizing the pressure chamber. The moisture available in the airline will react deeply with urethane resins and rubbers. When this happens, it will cause foaming or bubbles. The airline driers can be found from industrial supply stores and dealers.

V. Importance of Pressurized Casting

Pressure die casting is fast and highly convenient compared to other methods. This makes it reliable and very cost-effective. It is mostly used by those looking to producing high volumes of professionally casted metal components that are net-shaped with tight tolerances.

The pressure die casting technique encompasses injecting under high pressure a perfectly molten alloy into a steel mold. This will then get solidified fast to form a net-shaped component. The casters will automatically extract it.

Let us take a look at some of the basic importance of pressurized die casting

- Highly cost-effective compared to other methods

- Castings done within thin walls, which makes them lightweight

- Castings are done with close dimensions control and excellent surface finish

Before we continue, it is worth mentioning that there is high-pressure casting and low-pressure casting. Therefore, you need to understand the exact type of machine you need to use for the casting process. High-pressure casting will always feature a wide application of at least 50% of all casting production. In the current market, low-pressure casting only accounts for 20% of the entire production, but its use has also increased over the years.

VI. More about High-Pressure Casting

In this case, the liquid metal gets injected with high pressure and speed into the metal mold. The basic equipment features two vertical platens. The bolsters are then placed on the two platens and to hold the die halves. One of the two platens is movable while the other one of fixed. This kind of model will help the system to open and close. A given amount of metal is then poured into the shot sleeve. Later on, it will be introduced into the mold cavity. This must be done with the help of a hydraulically driven piston. Once the metal has solidified, the die gets opened, and the casting is removed.

VII. What about Low-Pressure Casting?

This is the method that is used when you want to manufacture high-quality aluminum alloys together with magnesium and other alloys with very low melting points. Most of the time, aluminum with the weight range of 2-150 kg is cast using a low-pressure casting method.

This is how the process works. The metal die is placed above a furnace that is sealed and contains a molten metal. A refractory-lined riser then extends from beneath the die all the way into the molten metal. Low-pressure air of between 15-100 kpa, 2-15 psi is deployed into the furnace. This will then make the molten metal to rise up the tube and before entering into the die cavity with very low turbulence.

Once the metal has solidified, the air pressure gets released. This will make the metal that is still in a molten state in the tube riser to collapse back right into the furnace. Once the subsequent cooling has occurred, the die gets opened, and the casting is extracted.

VIII. Platinum Devesting

You will learn that there are quite some challenges in removing the investment. The investment is usually baked at very high temperatures, which make it turn into a glass-like substance that can be hard to remove from the cast pieces.

To most manufacturers, hydrofluoric acid works best, but this might be extremely dangerous, especially when you are a novice. If you have to use this method, then you must be very cautious. Make sure to use some rubber gloves, a respirator, and a rubber apron. The respirator helps to filter tiny particles from the air.

If you run a smaller shop, then you might need to use a devesting agent that is created specifically for platinum investment. It is used as the best substitute for hydrofluoric acid. Since there are several brand names, you want to ask your supplier about the right one to use. We can give you detailed information on the same to ensure that you are safe.

Understanding the Process of Platinum Casting

To cast platinum, it is essential to understand how the entire process works. You should also be able to repeat the same functions on a consistent basis. Due to enhanced technology, small scale platinum casting has become easier than ever.

Ricardo Basta, in 1986, chose to start platinum casting. He spent a lot of effort trying to learn everything possible regarding the process. Unfortunately, he never achieved substantial success. He wanted to understand the properties of platinum as well.

No one had an idea of how to cast platinum when Eichberg started. He worked alongside a few employees. Interestingly, they were not even aware of the essence of insulating gloves and their ability to protect them from burning. Most of the time, they had wet rugs around their arms and cheeks to keep them safe. They were not adequately equipped.

Eichberg never gave up anyway. Through trial and error, he started the learning process. If you looked at his first casting, you would be convinced that he lacked experience. He had quite a number of drawbacks, such as cracks in the metal, no so good surfaces, and porosity. In case there was a problem, he tested many things until he got a better casting.

The popularity of platinum is just fairly good, which means that the learning curve with the metal has decreased exponentially over time. In the few previous years, the level of demand for platinum has increased significantly. Due to the increased demand, more manufacturers contemplate joining the industry of smelting and casting platinum. If you have been thinking of joining this industry, then you are on the right track. If anything, platinum casting is not as hard as it used to be back then.

It is imperative to note that platinum casting is a little different compared to silver and gold casting. Unless you are prepared for the process, and that you understand it well, you will just go through lots of frustrations. To achieve a good level of success, you ought to have the proper equipment and elaborate process control. We are about to let you know everything regarding casting platinum to get you started.

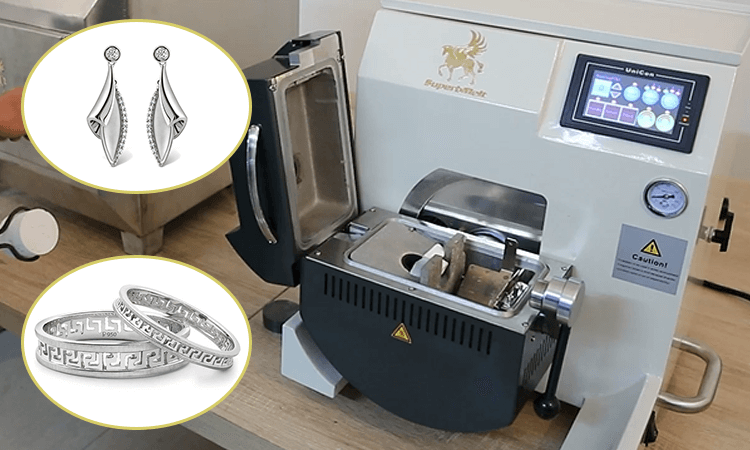

How to Cast Platinum By Superbmelt Mini Vacuum Casting Machine

SuperbMelt vacuum jewelry casting kit (SPB-MVC150) is a top-quality product that is specifically designed to hold metals whose weights do not exceed 150g.

The mini vacuum metal casting machine comes with quartz and an inbuilt furnace. It is capable of heating up to a maximum temp of 2600℃. The above features make this product suitable for casting hardened metals such as gold, platinum, palladium, and silver.

Jewelry casting kit (SPB-MVC150) is equipped with a gas chamber. The gas chamber that releases pressurized inert gases, which completely eliminate any form of porosity and oxidation during the casting process. This feature that gives your final cast as touch of class and quality.

- This lost wax casting equipment is designed for casting only a small quantity of precious metals (within 150g). It is designed very simple, leaving room for a DIY casting.

- This product comes with an inbuilt vacuum pump as compared with other castings kits in the market, which doesn’t always come with a vacuum pump.

- The automatic intelligent Simen control system (PLC) makes your whole casting process very safe seamless.

- The vacuum casting machine automatically stops the machine when an error is detected.

- This product is designed fully automated. Both your melting and casting chambers can be flipped automatically during operation. This feature saves you more money in terms of manpower needed to handle your casting operations.

- The precious metal casting equipment can cast any of your precious metals in the shortest amount of time possible. This machine is capable of reaching your metal casting temperature (max. temp of 2600℃) in split seconds by a 4.5Kw induction generator

- The furnace powerful inbuilt generator speeds up your production process coupled with savings in utility for power consumed.

- The Simen intelligent Control system (PLC) of the mini jewelry casting tool gives more accuracy to your temperature readings. This furnace controller can measure any temperature up to an accuracy of ±2°C.

In conclusion, are you on the lookout for compact and small-sized metal casting kits? A casting kit with an inbuilt metal melting flip that can automatically rotate your chamber. Then, the vacuum jewelry casting kit is your best bet.

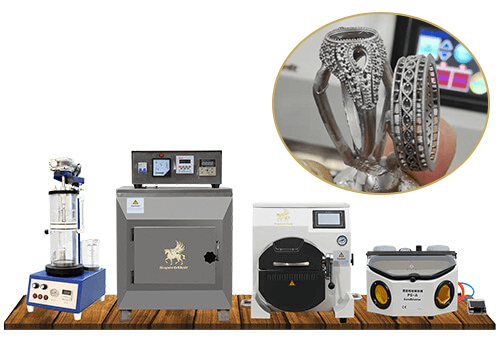

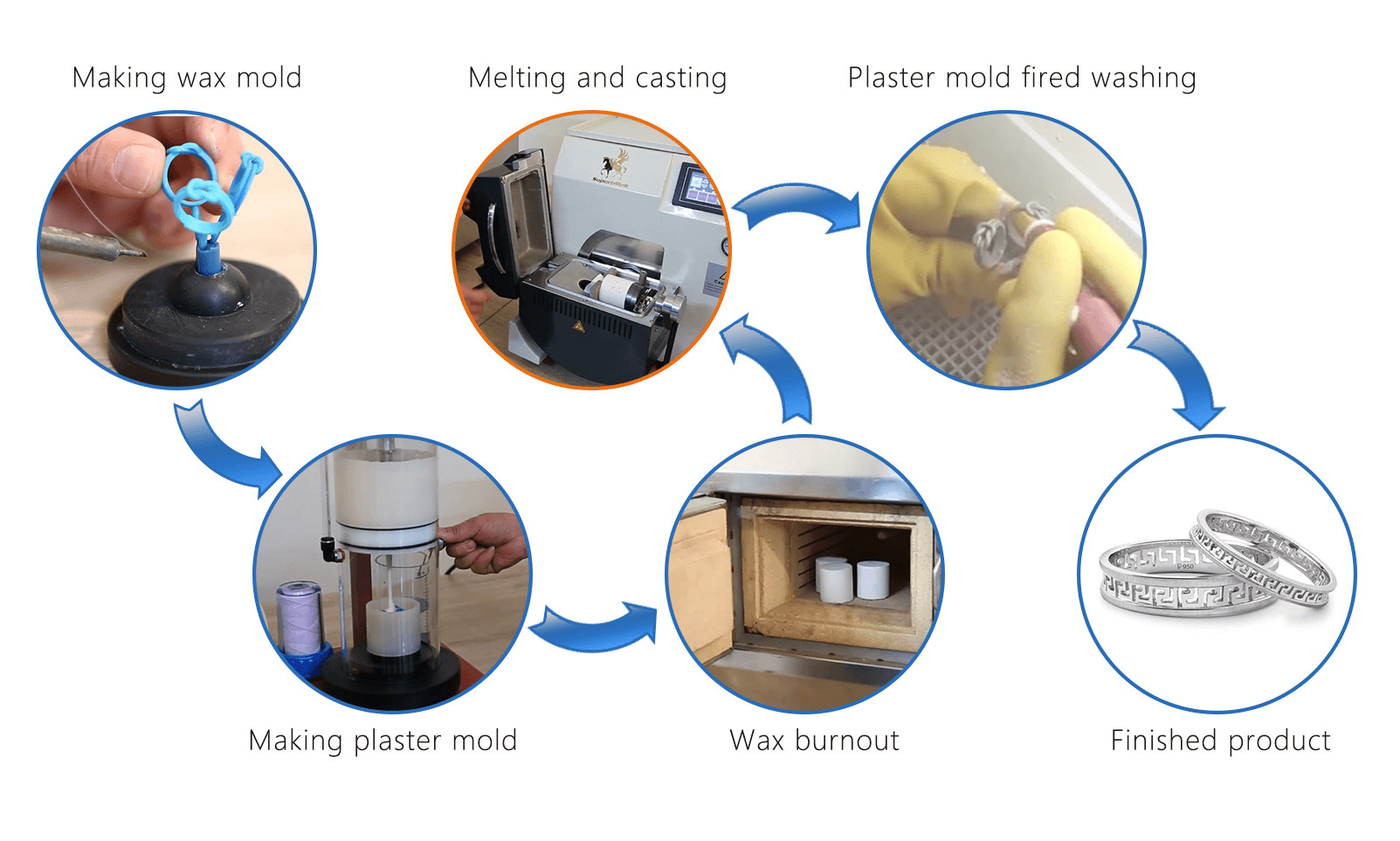

Steps for Casting Jewelry via the Vacuum Pressure Casting

- The initial stage involves getting the wax ready. It is advisable to weld the wax mold into a wax mold tree (you can copy the wax molds in batches with a wax injection machine, or you could print them with a 3D printer.

- Use a vacuum powder mixer to create a lost wax casting mold

- With a wax burnout furnace to have the wax melted out of the mold

- You can then melt the precious metal to fill the whole gypsum of the vacuum pressure casting machine

- The uneven piece of the jewelry is created after the cooling of the melted wax

- Now you can remove excess plaster using a plaster cleaning machine. The process is done and you can go ahead and start selling your jewelry.

You can bank with Superbmelt to provide you with a one-stop production line solution. The production package ranges from on-site guidance, equipment, and engineers to help you scale through the process.

Superbmelt is committed to solving your casting problems while proffering step by step guide to precious metals. We have been at the forefront of the Jewelry casting industry for 15+ years. We possess professional and meticulous engineers’, on-site training service, and a casting experience of more than ten years.

Superbmelt has helped build dozens of jewelry casting production lines in places like India, Dubai, Australia, Qatar, etc. Our engineers have rich experience in crafting a complex and unique piece of Jewelry.

How Does Superbmelt’s Vacuum Casting Process Solve the Problems Caused by the Casting Process?

The platinum casting process is not simply a walk in the park. Even by following the right procedures, there are certain problems that you have to deal with. Thankfully, our team at Superbmelt has the most applicable solution for you. Read on to discover some of the issues our company is there to help you with.

1, Air Entrainment in Wax

Bubbles that are found under the surface of the wax can either appear when air found in the mold is trapped amid the wax injection process, or when it is introduced into the mold alongside the wax. Regardless of the case, the air bubbles might pop if it happens that the casting equipment gets vacuumed. The void gets filled when the bubbles pop, and the investment gets slurry. Later on, the metal gets filled around the investment formations. Most of the time, they appear as tiny round holes in the castings.

SuperbMelt will always inspect investments for the availability of bubbles. This is done by holding them up to a source of light, and then looking through them. If you see some light spots, it means that there are bubbles in the wax, and they need to be removed. It is the readability of your wax that determines how easy it will be to see the bubbles. You will then remove the bubbles using a heated wax tool to pop them. You will see exposed holes that you need to fix with wax. These things can be done by SuperbMelt, and we will ensure that you get nothing but quality work.

Wax in molds tends to have different viscosity. However, this will not deter you from seeing the imperfections that you need to fix. There is only one perfect way to deal with the bubbles, which is by eliminating the source of the bubbles. The nature of the air you intend to remove dictates the method used to remove them. The air might get trapped amid the injection process, or it might have been introduced alongside the new wax.

It is advisable that air should leave the mold at a faster or rather equal rate compared to the wax that is being injected. It gets trapped if this does not happen. These trapped can be removed or prevented by applying powder properly in mold vents. This will then clear air from the mold cavity amid injection. You can also reduce trapped air in molds through the reduction of pressure and then slowing down the injection rate.

There are some instances in which air might get rapped in molds, especially if the air has to flow backward in the form of turbulent to fill the pattern. This is always the case due to the manner in which the model is gated. Some problems in casting might be caused due to the method of gating configuration.

Air can also be introduced in the mold alongside the wax that comes from several sources. Dissolved gas is one of the many sources of air that can be introduced into the mold. Another instance is when air gets trapped when fresh wax dots or chips are introduced into the wax pot. What happens that the tiny air spaces in between the cold wax chips get covered by molten surfaces before they can escape. These bubbles could get trapped until they get injected into the molds.

To overcome these challenges, you need to pre-melt the wax in the reservoir unit and then vacuum de-gas it having it loaded into the production wax pots. Superbmelt will use a transparent lid that has an airtight lid, with a fitting for the vacuum line alongside a separate vacuum release valve. In case these resources are not available, you can choose to vacuum de-gas the production pots. While doing this, make certain that the pressure gauge is well isolated on the wax pot amid the vacuum de-gas process. To do this, have a small ball valve installed between the wax pot and the gauge. Then make sure to close the valve when you are about to start the vacuum pump. You must never de-gas a full wax pot since some wax might end up in the vacuum hose. Water vapor is another source of air that gets trapped in the mold. This comes from condensation that happens in the compressed airlines.

2, Wrinkled Surface

Wrinkled surfaces can be caused by a number of factors. For instance, if there is an inadequate escape route amid wax injection, the wax pattern might not fit completely. This defect usually leads to another, which means avoiding them is necessary. If the pattern doesn’t fill, this then makes the worker increase the injection pressure. Once the injection pressure has gotten so high, the worker is compelled to apply a higher clamping pressure on the mold. This is done to prevent the wax from leaking out through the sides. Many other problems can also be encountered.

Due to the mistakes in the combination of the three pressures-injections, forward and clamp-pressure usually features seams and non-fills. It might as well lead to the wax-bubble problem. In case of too much forward pressure, the mold might split to let more air into the wax stream. The mold has a tendency to split, which makes an additional pressure of clamping necessary. This helps to keep the wax from leaking. Due to extra clamp pressure, small vents could be closed to trap some air on the inside.

This problem normally comes about due to hand wax injection due to the variable nature involved. It is crucial to avoid this problem at all costs, and this is where SuperbMelt comes in. With the auto-clamp system, you can discover, document, and repeat the proper pressure combinations, thereby letting you get rid of the three pressures from the affected areas.

3, Tree Building Defects

Wax tree is another main source of defects. The quality of the connection between sprue and the gate is the main issue we are talking about here. The get is the section that connects the jewelry wax piece and the central trunk of the wax tree. Central talk can also be referred to as the sprue.

The sprue/gate connection must be smooth and sealed all the way around. It is not advisable to use a wax pen to create a hole into the sprue and then having the gate inserted into the wax spot, but this is the mistake made by most individuals. If this method is used, it leaves many sharp inward points or angles in the wax. This will finally turn into sharp pieces of investment, and they can break off during the casting process. When this happens, they get pushed toward the exteriors of the mold cavity due to the disparity in the overall density between the investment and the metal.

It is possible to use a wax to create a filet at the base of the sprue/gate junction. This will help you avoid the possible situation that might ruin everything you have been working on. There is a better solution, which involves using a tiny smelting reservoir and sticky wax to get the job done a little faster and minimize the chances of defects. Even with this, sealing the base of the sprue/gate is necessary. This way, you will be able to come up with a smooth filet.

Even with the sticky wax, you still need some ea pen to get the parts sealed. Once you have dipped the end of the wax gate inside the sticky wax, the moving time between sprue and wax reservoir will allow the sticky surface to cool down slightly. Once this has happened, the unsealed gate might come off the sprue wax. This problem can be avoided by picking up the wax pen once per column or row and then sealing them.

4, Dewax Defects

At Superbmetl, we have what it takes to see that you are getting the best services at all times. Dewax defects is one of the main problems associated with platinum casting problems. But we are here to ensure that this does not bother you. Below is how you can dewax without the worry of observing any defects once you are done with the process.

Now that you have the mold and are ready to remove the wax, let’s show you how you can do it. Make sure that the molds are put into an autoclave while the wax is exposed, with the end facing downwards. During this time, the autoclave must remain closed. The steam should be injected into the autoclave within the shortest time possible. The steam will then pressurize the vessel to expose the mold to very high temperatures that go beyond 300F. The steam is the one that heats the wax. The steam pressure is necessary to offset the pressure due to the heating. This process will then expand the wax on the inside of the molds.

The wax will keep heating, and while it does so, it melts very fast and drains rapidly from the open end of the mold. This method is reliable since you will have 100% of the wax captures and then recycled so that you can use them again later on. The molds will be removed from the autoclave within a very short time. You will then let them cool down and dry.

This is mainly done in investment casting. Other casting methods also have their unique ways of getting things done. You will learn that they require the molds to be opened before the pattern can be removed. However, in investment casting, you can simply have the pattern melted, thereby allowing for improved detail in a perfect mold.

5, Cold Shuts

Cold shuts are surface imperfections that might occur in a material regardless of the casting or molding process used. We are talking about defects that can be seen by an unaided eye. These imperfections usually lead to rejection of the castings, which means that they need to be avoided at all costs. They might as well be referred to as the cold lap points. At Superbmelt, we have everything in place to ensure that these mistakes do not occur.

Cold shuts might take place when two metal streams fail to fuse together perfectly. This usually leads to some discontinuity or rather weak spots on the inside of the casting. Most of them tend to look more like cracks. Low pouring temperatures, too cold shell or slow pouring speeds are some of the major potential causes of cold shuts.

How does Superbmelt’s vacuum casting process solve the problems caused by the casting process

Platinum is a unique metal with lots of interesting properties. We believe that you learned a lot about the substance, including when it was first mined. Note that platinum casting is a complex process that needs to be done by experts, especially if you are looking to start a smelting and casting company.

We have been key players in the smelting and casting industry and can take care of any type of metal. Superbmelt brings to you 15 years’ worth of experience. We have worked with clients from different parts of the globe, and have always ensured that they get value for every coin paid.

Since we leverage some of the latest technology in the smelting and casting industry, we are the right team for you. Kindly get in touch with us using the contact information on our web page, and we will be there to answer each question you have for us. Better still, you might be looking for some of the best casting and equipment. We have them for you, and they go at very affordable prices. You can still talk to us about that, and we will have a great deal for you.

Platinum Casting Equipment Buying Guide

Whether you are an established company or a start up, knowing what to consider when buying platinum equipment is important. We do care for you, your money, and the productivity of the company. Therefore, we believe that with this buying guide, you will not make a wrong investment. Take a look at some of the things you should be looking for before making a purchase.

- Consider the Price

Nothing is more important than thinking about the price of the product. Though you are looking to optimize the productivity of your company, make sure that you do not put all your money into this single bit of the project. Do your homework and come up with a budget. This budget will help you determine the maximum amount of money you can spend on platinum casting equipment. Note that it is possible to determine the budget by coming up with an integral plan. If you are looking to do lots of production, then you will need an advanced machine, which might cost a little higher.

- Consider the size of the production

Your choice of platinum casting machine should be inspired by the scale of production for which you intend to apply it. There are platinum casting machines of all sorts. If you are looking to do a lot of production, then you need to get a machine that can easily stand that sort of work. However, there are ones meant for small shops, and they are great for small scale production. Before you start shopping, understand the nature of your company along that line, and you will never go wrong. Superbmelt should be your number one stop if you are looking for machines that match the type of work you intend to do.

- Consider the features

Always invest in machines that feature unique features to enhance the productivity of your company. Understandably, the features play a central role in determining the prices of various casting machines available. However, if you go for the best, then you will always have a long-term financial gain because you shall have gained a competitive edge. Some machines are automatic, while some come with parts that are mostly manual. Note that because a machine is manual does not mean it won’t function optimally. Just take your time and think carefully so that you make the best decision.

- The reputation of the Manufacturing Company

Many manufacturing companies join the market almost every other day. Some of them are good, while others are only there to make money. Therefore, before making an investment, you have to do your homework thoroughly. Maybe you want to create a list of all manufacturing companies and then doing a background search. You need to find out the nature of the machines they make and how they perform. Unless you do your research well, forget about getting the best item for your production. If you check, you will learn that Superbmelt has some of the best machines that have been bought by clients from all parts of the globe and that they work perfectly.

- Durability

It is great to use products that will last long enough. You don’t want to go shopping every other day. To overcome such issues, you want to secure platinum casting equipment that will last several years before you need to get a new one. Also, durable products are those that do not require regular maintenance. They can withstand elements without being degraded. Superbmelt deals with such products, and they have gained a good reputation in the market due to the quality of products that they sell. Our products are the best because they come with unique features that are also durable. You can regulate them to hit any rate of performance you need.

- Environmental Friendliness

All manufacturing industries are aware that the environment should be prioritized. Their applications must be ones that are focused on quality outputs that do not, in any, way interfere with the environment. At Superbmelt, we are always on the frontline on the fight against the emission of elements that might cause health complications among the users. Therefore, talk to us today, and we will help you get something that you will enjoy using for years to come.

- Maintenance Cost

Best platinum casting equipment should be one that does not subject you to expenses every now and again. And when they do, it should not be overwhelming. Therefore, you want to use a product that has features that are well developed so that they do not get spoilt every now and again. This might add to durability, but maintenance might also come depending on the nature of the application.

FAQ Guide

How long does the platinum casting process take?

The duration to cast platinum varies depending on the shapes and patterns you are looking to make. It is also determined by the machine that you are using to do the work. The process might take between ten minutes and one day. Note that the level of expertise of the workers will also determine the duration it takes to get platinum cast.

How can I prepare platinum for casting?

The preparation bit is vital, and it might take you time to get ready, especially if you are a novice. You need to have a torch, platinum casting equipment, insulated gloves, the best casting alloy, eye protection, and a devesting solution. If you are not certain about any of these things, talk to us, and we will be there to help you out.

Are there risks involved in platinum casting? How Can I avoid them?

Yes, there are several risks involved in casting platinum. You want to make sure that you have the right items in place to avoid any accidents. First, you might learn that the surface of the mold is not even or that there is some air trapped on the inside. Superbmelt has the right solutions to such problems. Also, you should have protection gear so that you are safe from possible accidents that might occur.

What is the right temperature for platinum casting?

To melt and cast platinum, you will need a temperature ranging from 332 degrees F to 3992 degrees F. Note that while heating, you will need an oxygen flame to melt the substance. This is because you can only get the hottest temperature from oxygen. You will need a platinum casting torch to have the substance melted.

What is the cost of casting platinum?

There is no precise answer to this important question. However, using the essential factors, you can determine the approximate cost of casting platinum. You will need casting equipment, torch, and some basics that we have mentioned above. The amount of platinum you want to cast can also determine the overall budget. Make sure that you have enough room and workers, but you might need to pay them.

What is jewelry wax?

This is a very uniquely designed wax, that is mainly used to create jewelry pieces in the lost wax casting process. These waxes are mostly hard and are meant to be carved. They can be filed, polished, and sawn. The wax is essential because it is used to design the jewelry piece that needs to be created. We can help you with most of these things at Superbmelt.

Can platinum casting equipment develop glitches?

Yes, the machines are created to make the work easier for you. But they have their own drawbacks, which is why you are supposed to know how best to handle them. Even the best equipment from a renowned company might develop some complications. These can happen at any moment and can reduce the productivity of your company. It is best to know how to diagnose them on time.

How can I troubleshoot platinum casting equipment?

These products are quite complicated. At some point, you might need a technician to help you troubleshoot them. However, you can still do the work on your own as long as you follow the right procedures. Discuss with your supplier about the right melting and casting temperatures. Make sure that you set your machine accordingly so that the heaters are not affected. If you are using a melting torch, you want to cast not more than three seconds after metal puddles.

Can Platinum Rust?

Just like gold, platinum is highly resistant to rust. It does not tarnish, corrode, or change color for many years. This makes it one of the best metals to create jewelry products. Compared to gold, platinum is 40-60% heavier. However, you still want to maintain the top quality of your precious metal by not subjecting it to harsh elements.

Can Platinum be used to make home appliances?

Platinum has a wide range of amazing properties, which means it can be used for a wide range of reasons. Platinum can be used to make important parts of electronics. To be precise, the answer is yes. Platinum can and has been used to make a wide range of home appliances. The kitchen, bathroom, and laundry appliances can be made from platinum.

Is platinum toxic to humans

Platinum is a noble metal. It occurs naturally and might have come concentrations in the soil, water, and air. This metal has characteristics that make it stand out from the crowd. It is great to mention that it might cause some toxicity, especially when combined with other chemicals in the human or animal body. One such chemical is known as selenium.

How Reactive is Platinum?

Naturally, platinum is chemically inert. This implies that it will never react in the air at any given temperature. We believe that this is a great property to have. It is also highly resistant to acids and cannot be attacked by any mineral acid. However, platinum readily dissolves in aqua regia. The metal can be rapidly attacked by fused alkali.

What Color is Pure Platinum?

Pure platinum is pale grayish-white. If you have anything other than this, then you might be looking at impure platinum or something very different from it altogether.

Can platinum be used in healthcare?

Platinum is a precious metal that has been used in a wide range of industries, and healthcare is not an exemption. It has been used to make various laboratory equipment such as thermometers.

Which industry depends on platinum the most?

Platinum is unique in every sense of the word. Therefore, it has a high value. Jewelers are the ones that enjoy the quality of this precious metal the most.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited