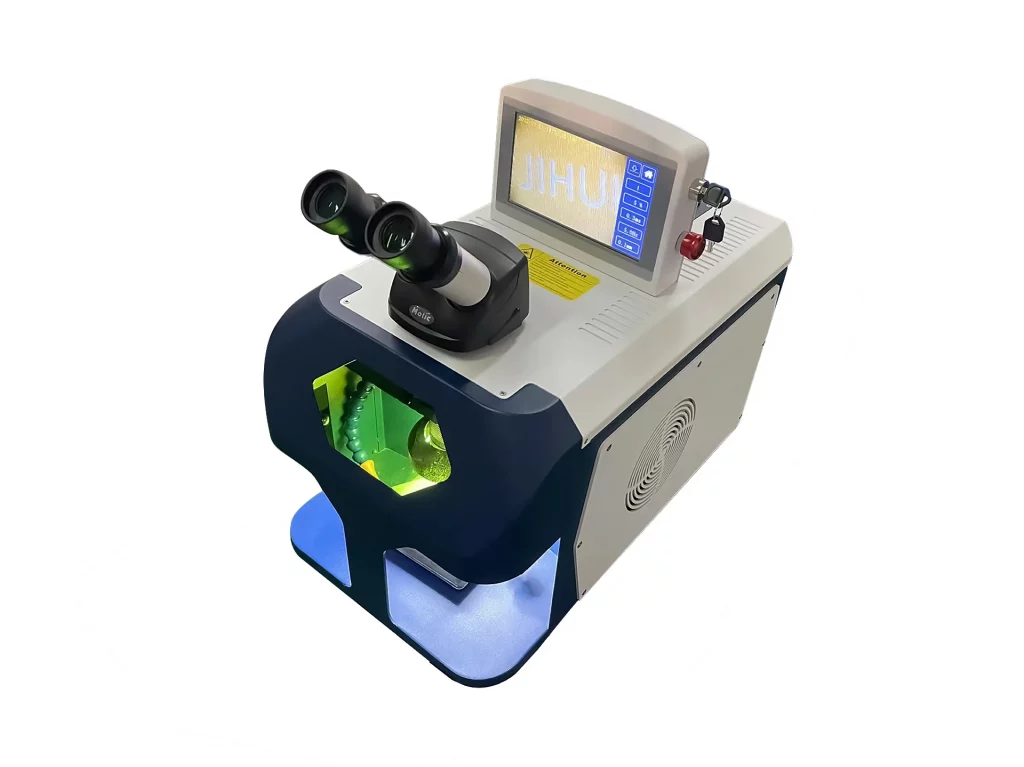

Gold Laser Engraving Machine

SuperbMelt 20w-50w laser engraving machine can customize patterns on any precious metal jewelry.

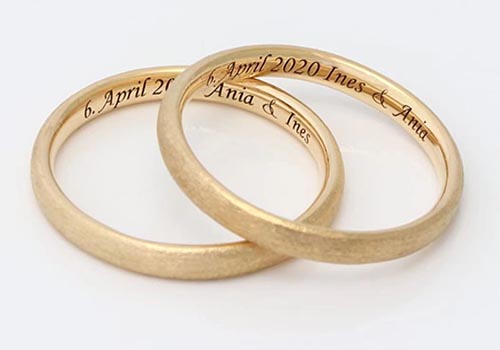

SuperbMelt Gold Laser Engraving Machine helps small jewelry shops achieve customized services. This machine is primarily used for permanent laser engraving of patterns and text on precious metal jewelry such as gold, silver, and platinum without damaging or altering the material itself.

Compared to traditional engraving methods, laser engraving offers significant advantages. It enables precise engraving without damaging the material. This laser engraving machine is not only suitable for the jewelry industry but also for other fields such as medical devices, electronic components, and bicycle manufacturing.

Utilize the SuperbMelt Gold Laser Engraving Machine to drive business growth and assist more customers in creating customized jewelry pieces!

| Model Number | SPB-MFLM |

| Average Output Power | 20W/30W/50W |

| Beam Quality | M²:1.5(TEMOO mode) |

| Repeatability | 0.01mm |

| Max Line Speed | 12000mm/s |

| Min Line Width | 0.017mm |

| Power Adjustment Range | 1%-100% |

| Laser Wavelength | 1064nm |

| Total Power | ≤500W |

| Marking Range | 110mm*110mm/175mm*175mm |

| Cooling System | Air Cooled |

| Laser Repetition Rate | 20KHz-80KHz(Adjustable) |

| Equipment Working Environment | Clean or Less Dusty |

| Min Character | 0.2mm*0.2mm |

| Equipment Operating Temperature | 13℃-28℃ |

| Marking Depth | 0.01mm-1mm(Determined by material) |

| Power Requirements | AC220V/50Hz/2A |

- High Stability

The laser is transmitted through an optical fiber, where it undergoes stimulated oscillation within the fiber waveguide, resulting in low loss and high stability, ensuring high product yield.

- High Speed

The perfect combination of software and hardware with an ultra-high-speed imported galvanometer effectively increases productivity, with a marking speed of up to 10,000mm/s.

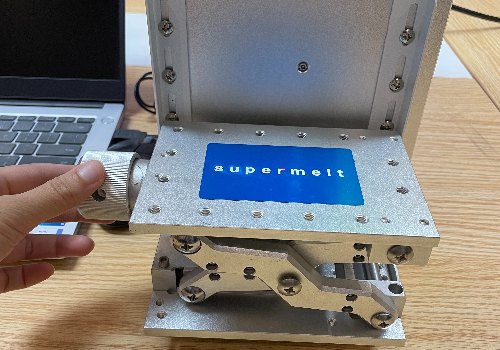

- Convenience

The overall machine is more compact, allowing for handheld operation and configuration for online flying marking.

- No Consumables

The fully air-cooled fiber laser has a long lifespan, requires no consumables, and features low maintenance and operating costs.

- Materials That Apply

Metals with a high melting point, high brittleness, and high hardness include stainless steel, gold, silver, copper, platinum, and aluminum.

There are also some electroplating materials, hardware, high-hard alloys and so on.

- Relevant Industries

Jewelry, timepieces, hardware components, 3C, electronic chips, processing of domestic goods, medical equipment, the advertising business, etc.

- Relevant Products

Personalized stainless steel kitchen utensils, mobile phone accessories, precision instruments, hardware components, clocks, eyeglass frames, and personalized rings, bracelets, and other precious metal items all feature laser lettering.

- Relevant Type

It is used to make metal nameplates, such as QR codes, bar codes, serial numbers, batch numbers, etc.; to indicate the metal purity of jewelry chains; to mark the manufacturing date of metal packaging; and to make logos and advertisements for various items.

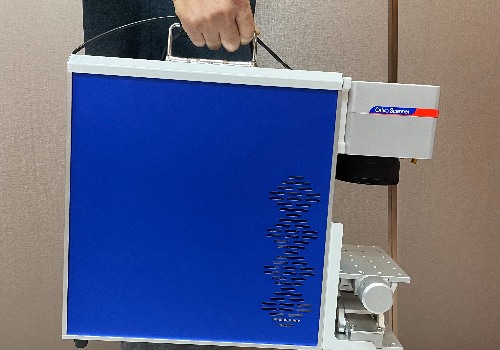

Portable Handling Equipment

The machine is compact and portable, and the handle installation may be readily transported to other settings. The enclosure is built of sturdy, high-quality materials that offer favorable working circumstances.

Rapid Marking Speed

The entire marking procedure is made simpler and faster thanks to the high-quality beam output and intelligent focusing mechanism, which also increases work efficiency.

Highest Precision

The accuracy is 0.002mm, and the plane may be used to achieve a variety of intricate shapes. The non-contact labeling lowers material loss.

SuperbMelt Gold Laser Engraving Machine Workflow

- Design Preparation: Create or import the design using appropriate software.

- Material Setup: Place the gold jewelry piece securely in the machine’s work area.

- Machine Configuration: Adjust laser settings (power, speed) and focus.

- Engraving: Start the engraving process.

- Post-Engraving: Clean and inspect the engraved jewelry.

- Completion: Finalize with finishing touches as needed.

Any Question About SuperbMelt Gold Laser Engraving Machine

Why SuperbMelt Gold Laser Engraving Machine

About SuperbMelt Automatic Laser Welding Machine Related Products

Here's What Our Satisfied Customers Have to Say

SuperbMelt Gold Laser Engraving Machine FAQ

- Getting ready the gold ring To get rid of any potential dirt, dust, or oils on the gold ring’s surface, clean it. To cover any sections of the ring that you don’t wish to be engraved, you can also want to use masking tape or a coating.

- Setting up the laser engraving device: Set up your laser engraving device in accordance with the directions provided by the manufacturer, making sure to choose the settings suitable for gold materials.

- Make or import the design: To create or import the design you wish to engrave onto the gold ring, use the software that came with your laser engraving equipment.

- Set the ring in place: Make sure the gold ring is firmly in place before placing it onto the laser engraving machine’s engraving bed.

- Start the engraving process by choosing the proper parameters for your design and launching the laser engraving procedure. A permanent engraving will be left on the gold ring after the laser beam removes the gold substance in accordance with the design you have produced.

Once the engraving process is finished, take the gold ring from the engraving bed, clean it completely to remove any debris or residue from the engraving process, and then check the engraved ring. Check the engraving on the ring to make sure it is accurate and up to your standards.

Stainless Steel, Aluminum, Brass, Copper, Gold, Silver, Titanium, Platinum, Nickel.

- The main difference between 3D laser marking machines and laser engraving machines is the type of marking or engraving they are capable of producing.

- 3D laser marking machines are designed to make markings or engravings with a three-dimensional effect, creating depth and texture in designs. These machines typically use fiber lasers to mark or engrave a range of materials, including metals, plastics, and more. They are ideal for creating high-precision marks with intricate details, such as barcodes, serial numbers and logos.

- Laser engravers, on the other hand, are often used to create two-dimensional engravings, such as designs or text, on various materials. These machines use a laser beam to cut or engrave the surface of a material, creating a permanent mark. Laser engravers are ideal for creating personalized gifts, signs and other decorations.

- Although both 3D laser markers and laser engravers use laser technology to create markings, their functions and applications are different. But SuperbMelt’s marking machine can achieve 3D effect by changing the 3D lens, so once you buy SuperbMelt’s marking machine, you can immediately realize 3D and 2D functions at the same time

- Design creation: Using computer software, the design or image that will be engraved is first produced. The laser engraving machine then receives this design.

- Surface Preparation: The material’s surface is prepped to guarantee a clear and smooth surface before engraving. This can entail giving the material a specific coating or cleaning the surface.

- Laser Engraving: The laser engraving machine employs a strong laser beam to engrave the design into the material once the design has been transferred and the surface has been prepared. In order to generate the design, the laser beam is directed onto the material’s surface and removes or vaporizes the substance.

- Finishing: Any extra material or dirt from the material’s surface is cleaned off once the engraving is finished. A finishing procedure may be applied to improve the engraving’s aesthetic or durability depending on the material being engraved.

- A laser engraver’s price can vary significantly based on a number of variables, including the kind of laser engraver (such as CO2, fiber, or diode), the machine’s size and power, as well as the manufacturer and the equipment’s quality.

- Different sectors have varied CO2 laser engraving machine prices, and more costly, industrial-grade equipment will cost more money.

- It’s vital to remember that the laser engraver may have ongoing expenditures, such as maintenance, replacement components, and software upgrades, in addition to the initial purchase price.

- A fiber laser engraving machine is a particular kind of laser-based equipment used to precisely and accurately engrave and mark a variety of materials. The device creates a laser beam that can engrave a variety of materials, including metals, plastics, wood, ceramics, and more using fiber laser technology.

- The laser beam is focused onto the surface of the material being etched after passing via a number of mirrors and lenses. The device can create a variety of effects, including deep engravings, surface patterns, and even 3D designs, by altering the laser beam’s strength and frequency.

- Because of their speed and accuracy, fiber laser engraving machines are well-liked in a variety of fields, including jewelry creation, manufacturing, and signs. They provide a low-waste, quick turnaround method for producing engravings of a high caliber.

- Materials: Metals including gold, silver, copper, and stainless steel are just a few of the materials that SuperbMelt’s laser engravers can work with.

- Size: To choose the ideal laser engraving machine for you, please take into account the size of the object you plan to engrave. SuperbMelt provides both big and small laser engraving machines.

- Power: SuperbMelt provides laser engravers in a range of power levels; while selecting a machine, take into account the amount of detail and speed your project calls for.

- Software: The laser engravers from SuperbMelt include user-friendly software that makes it simple to import and generate designs.

- SuperbMelt is a respected business with a strong emphasis on customer service, allowing you to shop with confidence and get assistance when you need it.

- Budget: SuperbMelt has laser engravers for sale at a range of prices to suit your needs.

- A 1D workbench may only move in one direction, usually left or right or up or down. Workbenches of this kind are appropriate for straightforward, two-dimensional engraving jobs.

- A 3D workbench, on the other hand, may move in numerous directions, often left and right, up and down, and forward and backward. This makes it possible to create more complex, three-dimensional engraving projects.

- A 3D workbench enables the laser engraving equipment to precisely engrave on curved or uneven surfaces by adjusting the laser beam’s focus and height.

Why You Could Choose Superbmelt

2 years warranty

The warranty for our machine is one year longer than the warranty provided by other factories.

ISO CE SGS approved

Professional certification bodies certify that the machines are of high quality.

Strong service team

We will give response within 24 hours against your problem by our professional engineer.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited