Printers That Print on Metal

SuperbMelt Metal UV Printing Machine, Developed Specifically for Coin Coloring

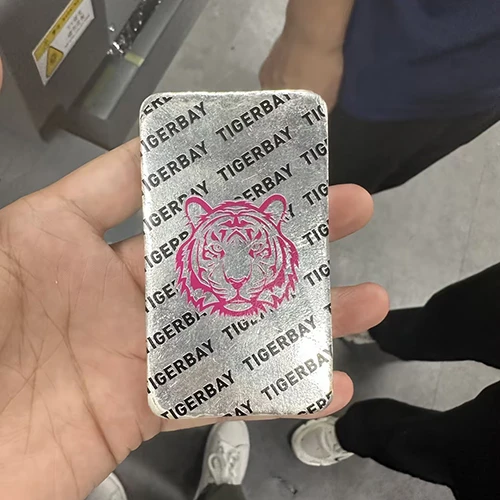

SuperbMelt Printers That Print on Metal allows seamless coloring on various metal surfaces, suitable for applications such as coin processing, intricate gold bar coloring, and coloring of metal artworks.

- Features:Compared to traditional printing, it is more resistant to fading, corrosion, and oxidation.

- Compatibility: Besides metal coin printing, it can also print on various materials such as wood, glass, ceramic tiles, rubber, PVC, and acrylic.

- Contrast:Compared to traditional printing, SuperbMelt UV printers have a faster printing speed, capable of printing 4m² per hour, which increases production efficiency and reduces labor costs.

SuperbMelt Printers That Print on Metal utilize UV printing technology with high resolution and environmental-friendly features. They utilize a vacuum suction platform for inkjet printing, achieving flawless inkjet printing.

| Model number | SPB-DY1612 | SPB-DY1012 |

| Power and Voltage | 2500W/220V | 2500W/220V |

| Dimensions | 3100*2000*1400MM | 2080*2580*1400MM |

| Printing Speed | 4M²/H | 3M²/H |

| Printing Method | Pressure Inkjet | Pressure Inkjet |

| Ink Cartridge Configuration | 1.5L | 1.5L |

| File Formats | TIF, JPEG, EPS, PDF, etc. | TIF, JPEG, EPS, PDF, etc. |

| Working Platform | Vacuum Adsorption Platform | Vacuum Adsorption Platform |

| Output Precision | 1220*720DPI | 1220*720DPI |

| Printing Material Height | 150MM | 100MM |

| Printing Size | 1600*1200MM | 1000*1200MM |

| Visual localization of print area(Optional Configuration) | 1520*1000MM | 840*1000MM |

Instant Curing

UV printing on metal surfaces allows for rapid curing of the ink, resulting in immediate drying of the printed patterns upon exposure to light. This eliminates the need for lengthy drying processes, enhancing production efficiency.

Durability

Printed materials that undergo UV curing exhibit outstanding durability on metal surfaces. They can withstand scratches, abrasions, as well as external factors like sunlight and rain exposure.

Vibrant Colors

UV printing on metal surfaces presents vivid and rich colors, adding a vibrant appearance to metal products. This is crucial for creating eye-catching logos and designs.

High Resolution

UV printing technology on metal surfaces achieves high-resolution printing effects, capturing intricate details and patterns, making it suitable for various complex designs.

Environmental Friendliness

UV inks used in printing contain fewer volatile organic compounds (VOCs), making UV printing on metal surfaces more environmentally friendly. This helps reduce the emission of harmful gases.

Temperature Resistance

After curing, UV printing can withstand higher temperatures, which is essential for the use of metal products in high-temperature environments.

Multi-Material Compatibility

UV printing is not limited to different types of metal; it can also be applied to composite surfaces with other materials, such as metal with plastic coatings.

Special Effects

UV printing machines can achieve various special effects, including gloss, matte, embossed textures, and patterns, adding a unique tactile sensation and appearance to metal prints.

Why SuperbMelt Printers That Print on Metal

Any Question About SuperbMelt Mini Gold Melting Furnace

SuperbMelt Gold UV Printing Guide

SuperbMelt Metal UV Printing

1.1, Working Principles of Metal UV Printing

By relying on the voltage within the printhead, ink from the nozzles is ejected onto the surface of the substrate, achieving the purpose of printing images. Generally, a small printhead contains thousands of nozzles, and the printhead controls the ink ejection amount from each nozzle. The ultraviolet (UV) light emitted by UV lamps reacts with the photosensitive curing agent in UV ink. This causes the pigment molecules in the UV ink to solidify on the material’s surface, achieving rapid drying of the ink. As a result, traditional processes like baking or air drying are not required. UV printers can precisely control the printing patterns on different materials and shapes, primarily relying on the principle of positioning:

- For X-axis positioning, a grating decoder is mainly used to direct the device’s lateral printing.

For Y-axis positioning, it relies on the drive of a servo motor to control the length of the printing material.

For Z-axis positioning, it mainly relies on the lifting function of the print head.

1.2, Applications of UV Printing on Metal

- Product Branding and Labels: UV printing on metal is used to create high-quality, durable product labels, tags, and trademarks, enhancing brand value and providing product information.

- Industrial Components: Metal components used in industries such as automotive, aerospace, and electronics can be enhanced with UV printing by adding identification codes, serial numbers, and instructions, aiding in traceability and quality control.

- Promotional Items: Promotional items made from metal, such as keychains, bottle openers, and pens, can be customized using UV printing, adding a unique and personalized touch for marketing activities.

- Signage and Nameplates: UV printing on metal is suitable for producing durable outdoor signs, indoor displays, and nameplates with intricate designs, vibrant colors, and resistance to environmental factors.

- Decorative Art Pieces: Metal artworks, sculptures, and home decor items can be adorned with complex designs and vibrant colors using UV printing, adding a distinctive aesthetic to living spaces.

- Consumer Electronics: UV printing on metal surfaces of electronic devices like smartphones, laptops, and gaming consoles can incorporate graphics, logos, and patterns, enhancing their visual appeal.

- Jewelry and Accessories: UV printing can add exquisite patterns, designs, and personalization to metal jewelry, watches, and accessories.

- Packaging: Metal packaging materials can feature branding elements, nutritional information, and decorative designs through UV printing, increasing their appeal to consumers.

- Customized Gifts: Personalized metal gifts, such as commemorative plaques, trophies, and awards, can be created using UV printing for special occasions and events.

- Automotive Components: UV printing on metal automotive parts allows for custom designs, decorative elements, and functional labels, contributing to both aesthetics and functionality.

- Medical Devices: Medical equipment and devices made from metal can be labeled with important information, instructions, and safety warnings using UV printing.

- Architectural Elements: Metal architectural elements like handrails, signs, and decorative panels can feature intricate designs and patterns using UV printing technology.

- Wine and Spirits Labels: High-end wines and spirits can utilize metal labels with UV-printed designs, highlighting the design and adding a sense of luxury.

- Sporting Goods: Metal sporting equipment, such as golf clubs and trophies, can be customized with player names, team logos, and other graphics using UV printing.

1.3, Features of SuperbMelt Metal UV Printing

- drying quickly to avoid contamination

The concentrated reflecting shield employed by the UV flatbed printer concentrates UV light energy for incredibly effective curing. The UV flatbed printer’s ink quickly dries, allowing for speedy drying and preventing contamination.

- Limited Energy Use

The UV flatbed printer achieves an energy-efficient 90% reflection rate by using mirror-finished aluminium oxide plates and a cold light source reflection.

- stable performance without radiation

Long-lasting UV flatbed printer with lampshade-shaped design that generates brilliant light without radiation for flawless printing outcomes. Its performance is consistent, allowing for quick drying and good ink stability, preserving longevity.

- Practically All Power Sources Compatibility

The UV flatbed printer requires little upkeep and uses only 80 watts of power, making it suitable for practically all power sources. It is a versatile piece of equipment that can be used for both home and office printing. It is a unique and adaptable gadget since the printed output dries rapidly without smearing.

How to Choose the Best Coin Printing Machine

Printing technology, print quality, material compatibility, production capacity, level of automation, reliability, and durability.

2.1, Coin Materials

- Aluminum Alloy Coins: Aluminum alloy is a common coin material suitable for UV printing technology, enabling high-quality patterns and details.

- Stainless Steel Coins: Stainless steel coins excel in durability and longevity, with UV printing adding decoration and identification.

- Copper Alloy Coins: Copper alloy coins are commonly used for commemorative and decorative purposes, with UV printing enhancing their intricate designs.

- Brass Coins: The texture of brass coins suits UV printing, resulting in a distinctive visual effect.

- Gold Coins: Gold coins are highly compatible with UV printing, allowing for the creation of unique anti-counterfeiting marks.

- Silver Coins: UV printing on silver coins produces beautiful and vibrant patterns.

2.2, Production Quantity and Efficiency

According to your production needs, choose the appropriate UV coin coloring printer for purchase. The production speeds provided by SuperbMelt’s metal UV printers are 4M²/H and 3M²/H, respectively. These two speeds are able to effectively meet the requirements of businesses producing small batches or large quantities of finished products.

Why Do We Need UV Printing Machines for Coin Production?

UV printing technology can achieve high-resolution printing, allowing for intricate patterns, logos, and details to be printed on coins. UV printing can incorporate special inks and effects, such as fluorescent inks, color-changing inks, etc., thereby enhancing the anti-counterfeiting properties of coins. UV printing technology enables a variety of colors, effects, and designs to be applied to coins, making the design more diverse and creative.

3.1, Value of Colored Printed Coins

- Colored coins can enhance their aesthetic value with vibrant colors and intricate designs, making the coins more artistic and visually appealing. Colored coins are often used to commemorate specific events, individuals, or celebrate significant occasions.

- These coins acquire unique commemorative value within specific historical or contextual contexts. Rare or limited edition colored coins often hold substantial value in the collecting market.

- Collectors might be willing to pay a premium for these distinctive colored coins. Businesses can utilize colored coins as gifts, souvenirs, or tokens, adding value to their products and enhancing competitiveness in the market.

- Colored coins may carry specific cultural, religious, or traditional significance, thereby preserving cultural value.

- Certain colored coins could appreciate over time, becoming part of an investment portfolio.

3.2, Printing versatility

- Enhancing Quality and Durability

UV printing is a high-quality printing technology that can create uniform and clear patterns and text on the surface of coins. These prints exhibit exceptional vibrancy in color, intricate designs, and precise details, thereby enhancing the coins’ visual appeal and texture. Moreover, UV printing can improve the durability of coins, making the printed patterns less susceptible to wear and fading.

- Fast Drying Speed

UV printing utilizes ultraviolet light to cure the ink, eliminating the need to wait for the ink to dry during the printing process. This speeds up production, significantly increases efficiency, and shortens production cycles.

- Environmental Friendliness

UV printing does not require the use of solvents, as ultraviolet light rapidly cures the ink without relying on the evaporation of harmful substances for drying. This reduces environmental pollution and lowers the emission of volatile organic compounds (VOCs) in the workplace.

- Printing Versatility

UV printing machines can be used on various materials, including metals, plastics, paper, and more. This versatility allows coin manufacturers to choose suitable materials based on their needs, enabling a more diverse range of coin designs.

3.3, Anti-counterfeiting capability

- Special Ink

UV coin printing can utilize special UV fluorescent inks, which are invisible under regular light but emit fluorescence under ultraviolet light. This enables easy authentication of coins using dedicated equipment or UV lamps.

- Anti-Counterfeiting Marks

UV coin printing can incorporate small, intricate patterns and marks that are difficult to replicate, such as microtext, QR codes, etc. These details increase the complexity of counterfeiting and enhance the anti-counterfeiting capability of the coins.

- Color-changing Effect

Some UV coin printing inks exhibit a color-changing effect, where the color shifts when viewed from different angles. This color-changing characteristic is hard to reproduce and can be used to deter counterfeiting.

- Coating Protection

Patterns produced by UV coin printing usually form a robust coating after curing, making the designs more resistant to wear or peeling. This enhances the anti-counterfeiting performance of the coins.

- Unique Designs

UV coin printing can achieve intricate patterns and designs that are unique. These distinctive designs make counterfeiting more difficult, contributing to the coins’ enhanced anti-counterfeiting capability.

Why Choose the SuperbMelt UV Metal Printing Machine

SuperbMelt is a manufacturer of UV printing machines. We possess the advantages of competitive pricing and fast delivery speed.

4.1, SuperbMelt UV Factory

SuperbMelt UV Factory is a manufacturer of high-end UV printing machinery and tools. We provide cutting-edge solutions for varied printing demands with a strong dedication to innovation and excellence. Modern equipment and knowledgeable staff at our state-of-the-art facilities ensure the creation of excellent UV printing solutions. Our UV printing equipment provide exceptional results that satisfy the various needs of our clients, whether they are complicated designs or vivid colours.

4.2, Robust after-sales service

To help, support, and cater to clients’ needs, we have specialists and customer relations officers on hand around-the-clock. We place a high priority on meeting the demands of our consumers, therefore whenever they contact us, we make sure that their needs are taken care of.

The following services are offered by our support service: responding to client inquiries, handling customer transactions, providing advice and direction, tracking product shipments till they are received, etc.

Conclusion

SuperbMelt stands as a pioneer in the realm of UV printing technology, providing advanced solutions for metal surface printing, particularly in coin production. With a focus on quality, innovation, and customer satisfaction, SuperbMelt’s UV printing machines offer a wide range of benefits that cater to the diverse needs of various industries.

The capabilities of SuperbMelt’s UV printers extend beyond traditional printing methods, revolutionizing the way patterns, designs, and logos are applied to metal surfaces. The utilization of special inks, anti-counterfeiting features, color-changing effects, and durable coatings enhances both the visual appeal and security of the printed products. This advanced technology not only enables intricate designs and vibrant colors but also ensures longevity and resistance to environmental factors.

SuperbMelt’s commitment to excellence extends beyond the manufacturing of high-quality UV printers. Their robust after-sales service ensures that customers receive ongoing support, guidance, and assistance, allowing for a seamless experience from purchase to utilization. With competitive pricing, fast delivery, and a wide range of applications, SuperbMelt’s UV printers are an optimal choice for businesses seeking to elevate their metal printing capabilities.

Whether for coin production, jewelry customization, industrial labeling, or artistic expression, SuperbMelt’s UV printing machines offer a versatile and reliable solution. By embracing cutting-edge technology, delivering exceptional value, and consistently exceeding customer expectations, SuperbMelt continues to pave the way for innovative and impactful metal surface printing.

About Printers That Print on Metal FAQ

- 1. How are Coloured Coins Made?

- 2. Are metal prints uv resistant?

- 3. What is a flatbed inkjet printer?

- 4. What does a UV flatbed printer do?

- 5. Is UV printing on metal durable?

- 6. Why do people color coins?

- 7. What paint do they use on coins?

- 8. What are the differences between UV printing and traditional printing methods?

- 9. Will ink printing on coins alter the weight of gold and silver coins?

- 10. Does printing on gold and silver coins alter the purity of the coins?

- 11. The product has a curved surface, can it be printed? Or are there products with varying heights?

- 12. What is the maximum height difference that can be printed? Does the machine model affect it?

- 13. What is the working principle of visual positioning? What is the accuracy error?

- 14. After printing, will the printing effect fade?

- 15. In the jewelry industry, many use adhesive processes for coloring. If UV printing is used instead, what are the differences compared to adhesive?

- 16. What materials can UV printers print on?

- 17. What are the advantages of UV printing?

- 18. Can UV printing be done on curved surfaces?

- 19. Are UV printed products resistant to scratches?

- 20. Are metal printed products UV resistant?

- 21. How many finished products can one run of the machine print?

- 22. What is the printing speed of the machine?

- 23. What is the printing sequence of the machine?

- 24. How much ink can the machine hold?

- 25. How much can 1 kilogram of ink print?

- 26. UV printing automatic visual positioning applicable products

- 27. How is the UV printing effect?

- 28. How to Choose Ink Based on Printing Material

- 29. How does a UV printer work?

- 30. What file format is used for printing?

1. How are Coloured Coins Made?

Design Planning: Firstly, a design plan for the coin is required. This involves determining the coin’s shape, size, patterns, logos, and desired colors.

Mold Making: Based on the design plan, molds for the coin are created. These molds will be used to cast the coin’s basic shape.

Metal Casting: Using the appropriate metal alloy, the metal is melted and poured into the molds. Once the metal cools and hardens, the coin can be removed from the molds.

Cleaning and Polishing: After removing the coin from the molds, cleaning and polishing are necessary to remove any residues and achieve a smooth surface.

Coloring: Using a UV printing machine, the coin is colored using special inks. The desired colors are placed into the ink cartridges of the UV printing machine, which is then activated to perform the coloring. This is done to ensure adhesion and durability.

Detail Processing: Depending on the design plan, further detail processing may be required, such as engraving, carving, or adding other special effects.

Final Polishing and Finishing: Lastly, a final polishing and finishing process is conducted to achieve the desired appearance and texture for the coin.

2. Are metal prints uv resistant?

Yes, metal prints produced using UV printing technology are equipped with UV resistance properties. UV printing utilizes ultraviolet light to cure the ink, thereby creating enduring and robust prints on metal surfaces. The cured ink forms a protective layer that mitigates fading and damage due to exposure to ultraviolet (UV) radiation from sunlight.

3. What is a flatbed inkjet printer?

- A flatbed inkjet printer is a type of printing device that utilizes inkjet technology to produce high-quality prints on a flat surface. Unlike traditional paper-feed printers that use rolls or sheets of paper, a flatbed inkjet printer has a stationary, flat printing surface where the material to be printed is placed. The printer’s print head moves back and forth across the material, ejecting tiny droplets of ink onto it to create the desired image or text.

- Flatbed inkjet printers are versatile and can print on a wide range of materials, including paper, cardboard, fabric, wood, glass, metal, and more. They are commonly used for various applications such as signage, promotional materials, packaging, art reproductions, and custom printing on various surfaces.

- These printers are particularly advantageous for printing on rigid or irregularly shaped objects, as the flat surface accommodates various materials and thicknesses. Additionally, flatbed inkjet printers often offer the capability to print in full color, allowing for detailed and vibrant designs to be reproduced accurately on a variety of substrates.

4. What does a UV flatbed printer do?

A UV flatbed printer is a specialized printing device that utilizes ultraviolet (UV) light to cure or dry the ink as it is printed onto a variety of flat surfaces. The printer is equipped with a flat, stationary printing platform where the material to be printed is placed. The UV flatbed printer’s key feature is its ability to rapidly cure the ink using UV light, allowing for immediate drying and adhesion to the substrate.

UV flatbed printers are highly versatile and can print on a wide range of substrates, including paper, plastics, glass, metal, wood, ceramics, and more. They are commonly used for applications such as signage, promotional materials, packaging, personalized products, and decorative items. The ability to print on various materials and achieve vibrant, durable prints makes UV flatbed printers a popular choice for both commercial and creative printing purposes.

5. Is UV printing on metal durable?

Yes, UV printing on metal is durable and offers excellent longevity. UV printing technology utilizes ultraviolet light to quickly cure and solidify the ink on the metal surface. This curing process creates a strong bond between the ink and the metal, resulting in a durable and resistant print.

6. Why do people color coins?

People color coins for various reasons, including enhancing their visual appeal, adding uniqueness, commemorating special events, increasing collectible value, and promoting branding.

Overall, coloring coins adds a layer of creativity and versatility to traditional coin designs, making them more engaging and appealing to a wide range of audiences, from collectors and enthusiasts to individuals and businesses looking for unique tokens or promotional items.

7. What paint do they use on coins?

Specialised inks or pigments created for numismatic purposes are used on coins instead of conventional paint, particularly in the context of numismatic art and collectible coins. These inks are designed specifically to attach to metal surfaces and offer durable, long-lasting colour. The following two inks are frequently used on coins:

- The numismatic business frequently uses UV (ultraviolet) printing inks to colour coins. UV light is used to cure UV inks, which causes them to dry quickly and adhere firmly to metal surfaces. These inks can produce colourful and intricate drawings on coins and come in a variety of colours.

- Epoxy Resin Inks: An assortment of coloured resins are put to the surface of the coin and then cured under strict control. The design of the coin is covered in an epoxy resin layer that increases the coin’s durability and resistance to wear, scratches, and fading.

Epoxy resin inks and UV printing inks both have advantages including vivid colours, fading resistance, and strong adhesion to metal surfaces. Their use enhances the visual appeal and collecting value of coins by adding complex and detailed designs to them.

8. What are the differences between UV printing and traditional printing methods?

- Printing Process:

Traditional printing methods use ink that requires drying through the evaporation of volatile organic compounds (VOCs).

UV printing utilizes ultraviolet light to cure the ink, eliminating the need for waiting for ink to dry and resulting in faster printing speeds. It also reduces VOC emissions.

- Effects:

UV printing can create high-resolution, detailed patterns and text on surfaces, enhancing visual effects and texture.

Traditional printing may have limitations in achieving the same effects as UV printing in terms of details and patterns.

- Durability:

UV printing forms a robust coating after curing, making printed designs more resistant to wear and fading.

Traditional printing may require additional processes to enhance the durability of the printed material.

- Environmental Impact:

UV printing does not require VOCs, and the curing process does not involve the release of harmful volatile substances, reducing environmental pollution.

Traditional printing methods may emit VOCs, contributing to environmental concerns.

- Printing on Various Materials:

UV printing can be applied to various materials such as metal, plastic, paper, offering greater versatility.

Traditional printing methods are often limited to specific materials, restricting their applicability.

9. Will ink printing on coins alter the weight of gold and silver coins?

It can be almost negligible

10. Does printing on gold and silver coins alter the purity of the coins?

No, it won’t change. Printing is only done on the surface of the coin.

11. The product has a curved surface, can it be printed? Or are there products with varying heights?

Curved surfaces are possible, but the smoother the curve, the better the effect. Avoid sharp angles for the best results.

12. What is the maximum height difference that can be printed? Does the machine model affect it?

The best effect is achieved at a height difference of 7mm, and the larger the difference, the worse the effect.

13. What is the working principle of visual positioning? What is the accuracy error?

Import the file in a 1:1 size on the software, scan the product’s position on the platform using the camera, and automatically configure the printing. The error is within 0.15mm.

15. In the jewelry industry, many use adhesive processes for coloring. If UV printing is used instead, what are the differences compared to adhesive?

Adhesive cannot achieve gradient colors and can only apply solid colors. It cannot print intricate patterns, and adhesive needs to be applied within product recesses. However, UV printing allows for more versatility in printing intricate patterns and can cover a broader range of surfaces.

16. What materials can UV printers print on?

Metals, wood, glass, acrylic, plastics, and other materials.

17.What are the advantages of UV printing?

Instant drying, all colors are formed in one pass, capable of printing gradients, can achieve partial embossed effects, strong adhesion, and allows for personalized customization.

18. Can UV printing be done on curved surfaces?

Partial printing can be done on curved surfaces, depending on the degree of curvature.

19. Are UV printed products resistant to scratches?

There’s no issue with nail scratching, and after applying the topcoat and UV curing, the printed surface can withstand alcohol wiping.

20. Are metal printed products UV resistant?

It lasts for about 3-4 years, varying based on the local intensity and duration of UV exposure.

21. How many finished products can one run of the machine print?

The printing area of the 1612 machine is 1520*1000MM. For example, if the customer’s finished product is 5231.2MM, according to the area calculation, it would be around 936 products. However, considering that customers won’t arrange them tightly and there will be gaps in between, the quantity is estimated at around 700 pieces.

22. What is the printing speed of the machine?

The machine takes 40 minutes to complete a full-page printing when filled with products.

25. How much can 1 kilogram of ink print?

1 kilogram of ink can print around 50-55 square meters.

26. UV printing automatic visual positioning applicable products

Conventional machines require fixtures for positioning during product printing. Automatic visual positioning scans the material’s position and angle, automatically configures patterns, eliminating the cost of fixture production and reducing the defect rate due to improper placement by hand.

Visual positioning is currently suitable for product conditions: 1. Small products 2. Irregular shapes 3. Low product thickness 4. High precision requirements 5. Small order quantities and customized products

27. How is the UV printing effect?

- Monochrome: It can achieve a semi-transparent effect that reveals the texture and patterns of the metal.

- White + Color: White covers the original color of the metal, and then color is printed on the white base. The color reproduction is high, and the surface has a matte effect.

- White + Color + Gloss Varnish: On top of the white + color printing, a glossy varnish effect is added, creating a shiny and glossy appearance with finer ink droplets.

28. How to Choose Ink Based on Printing Material

Selecting ink based on material is a common practice. For hard materials like metal or plastic, use hard ink; for soft materials like leather or PVC, use soft ink. Neutral ink is versatile but may not achieve the same printing quality as the other two options.

29. How does a UV printer work?

Print patterns are generated through computer control and are cured by UV light from the machine while printing. This simultaneous printing and curing process allows for immediate curing upon printing completion.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited