Roll Cutting Machine

SuperbMelt gold coil and silver coil cutting machine assists jewelry manufacturers in cutting and crafting jewelry

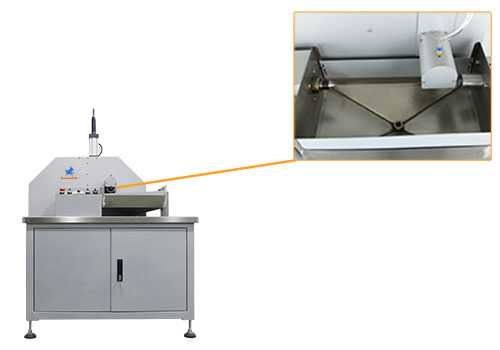

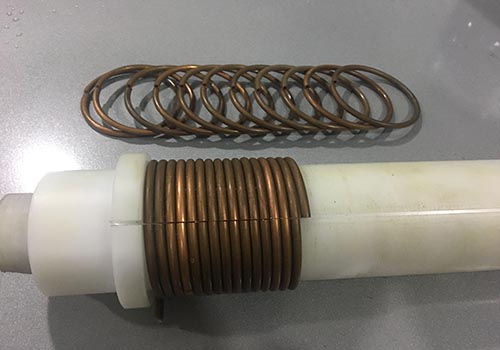

SuperbMelt Roll Cutting Machine is designed for cutting gold, silver, and alloy coil materials or tubular materials. It is used to cut pre-made semi-finished gold or silver bracelets, rings, or coils. The Roll Cutting Machine is commonly used in industries such as decorative arts, jewelry pendants, and handicrafts.

This machine features a spray cooling device to reduce the surface temperature of the saw blade, extending the tool’s lifespan. It can precisely cut materials and adjust to different widths and lengths as needed to meet various production requirements.

Utilize SuperbMelt’s Roll Cutting Machine to efficiently produce batches of bracelets and rings! Contact us immediately if you require other jewelry casting solutions!

- Smooth Cutting Edge: Equipped with tungsten steel saw blade, ensuring clean and smooth cutting edges without burrs.

- Stable Operation: Utilizes Taiwan guide rails for steady and creep-free blade movement, ensuring stable operation.

- Consistent Ring Opening: Ensures consistent ring opening with a tolerance of within ±0.03mm.

- Easy Operation: Simple operation with one-button control, easy to learn and operate.

- Spraying Cooling System: Equipped with a spraying cooling device to protect the mold and ensure efficient cooling during operation.

- Convenient Recycling: Features a funnel-type recycling tray for easy material collection and recycling.

| Model | SPA-Cir3 |

| Voltage | 220V |

| Power | 3KW |

| Pressure | 0.7MPa |

| Water consumption | 3L/H |

| Applicable metal | Gold, K gold, silver, etc. |

| Size | 700*600*1100MM |

| Weight | 71KG |

| Steam temperature | 100℃ |

Cutting the coiled jewelry materials facilitates subsequent processing of rings or bracelets.

The spillage loading area prevents material wastage.

Easy-to-operate control panel

Why SuperbMelt Roll Cutting Machine

Any Question About SuperbMelt Roll Cutting Machine

FAQ Guide of Roll Cutting Machine

- 1. A Roll Cutting Machine is a specialized equipment used for cutting metal coil or tube materials, such as gold, silver, alloys, etc. How does a Roll Cutting Machine work?

- 2. Which industries is a Roll Cutting Machine suitable for?

- 3. What are the advantages of a Roll Cutting Machine?

- 4. How to maintain a Roll Cutting Machine?

- 5. What is the cutting speed of a Roll Cutting Machine?

- 6. What safety precautions should be taken when using a Roll Cutting Machine?

- 7. How to adjust the cutting size and shape of a Roll Cutting Machine?

1. A Roll Cutting Machine is a specialized equipment used for cutting metal coil or tube materials, such as gold, silver, alloys, etc. How does a Roll Cutting Machine work?

A Roll Cutting Machine utilizes saw blades or other cutting tools to precisely cut metal coil or tube materials to meet specific size and shape requirements.

2. Which industries is a Roll Cutting Machine suitable for?

A Roll Cutting Machine is widely used in industries such as jewelry manufacturing, craft making, decorative production, etc., for cutting metal coil or tube materials.

3. What are the advantages of a Roll Cutting Machine?

- Smooth cutting edges, high cutting precision

- Simple operation, easy to learn and use

- Fast cutting speed, high production efficiency

- Adjustable cutting size and shape as needed

- Cooling system to protect cutting tools, prolonging lifespan

4. How to maintain a Roll Cutting Machine?

- Regularly clean the surface and cutting components of the machine

- Check if the cutting tools are worn or damaged, and replace them in time

- Maintain the lubrication of the machine to ensure smooth operation

5. What is the cutting speed of a Roll Cutting Machine?

The cutting speed depends on the hardness, thickness of the material, and performance of the cutting tool. Generally, it can reach dozens or even hundreds of cuts per minute.

6. What safety precautions should be taken when using a Roll Cutting Machine?

- Wear personal protective equipment such as gloves, goggles, etc.

- Keep the machine stable during operation to avoid accidents

- Do not place hands or other objects near the cutting components to prevent injury

7. How to adjust the cutting size and shape of a Roll Cutting Machine?

By adjusting the machine settings or replacing cutting tools, different cutting size and shape requirements can be achieved.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited