Rotating Burnout Oven

Superbmelt rotating burnout oven is mainly used for the combustion of plaster molds in lost wax casting, which is mainly used for casting in the jewelry industry.

The burnout oven in any casting house is a very critical piece of equipment. To achieve consistent results, it is of utmost importance to have correct temperature uniformly distributed throughout the chamber.

The equipment is equipped with a secondary combustion function to fully decompose harmful substances and meet environmental protection standards.

Parameters

| Voltage | 3-phase 380V, 50/60 Hz |

| Power | 15KVA (380V) (including secondary burner) |

| Weight | About 450 kg |

| Dimensions | 1020 (width) x 1020 (length) x 2130 (height) mm (Including secondary burner) |

| Max temperature | 850 °C |

| Furnace plate | Φ520mmx 2 furnace plates |

| Flask quantity | 37 (φ100mm) |

| 45 (φ89mm) | |

| Max height of the flask | 230 (height) mm |

Features & Benefits

- Uniform heating with minimum difference of temperature.

- Equal flask temperature distribution, uniform heat distribution with all the flask.

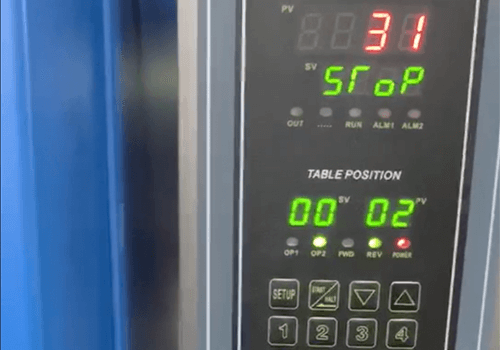

- Watch the exact temperature with the trace function.

- Over heating protection safety.

- Small door for less heat loss, minimal heat loss while opening the door.

- After-burner for environment and no smell.

- New after-burner with longer life.

- Good clean burnout for investment flask.

- Carbon free flask with good burnout cycle.

- User friendly operation and stable good result.

- No smell – less smoke – have after burner.

Why SuperbMelt Rotating Burnout Oven

Professional R&D Team:

Over 15 years R&D experience in gold machinery with a top engineer team supported

High Quality:

Only choose famous brand main electric components for production

ISO CE SGS Approved:

Professional certification bodies certify that the machines are of high quality

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited