Small Induction Furnace

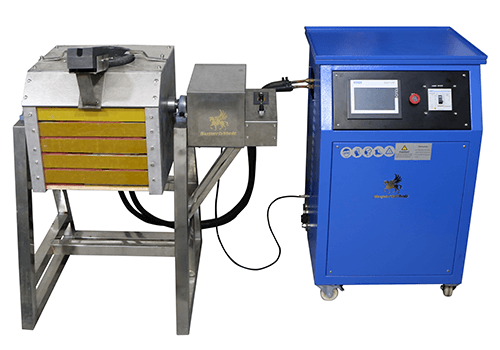

SuperbMelt small induction melting furnace (SPB-CTF) for 10-50kg non-ferrous smelting

SuperbMelt small induction furnace (SPB-CTF) can be used to melt any metal of choice. Both your ferrous and non-ferrous metals such as gold, silver and lead can easily be processed in no time. This small induction machine (SPB-CTF) can accommodate metals in the weight range of 10kg to 50kg.

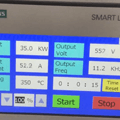

SuperbMelt small induction furnace (SPB-CTF) also comes with a digital Simen control system (PLC) It gives more precision and accuracy to your readings.

Have you got a small foundry, such as copper foundry, iron foundry, precious metal recovery plant, precious metal foundry? With the best price, SuperbMelt induction melting furnaces are got you covered.

Click here to see more metal melting furnaces with different capacity

- A small induction Furnace, capable of melting almost any metal of choice.

- SuperbMelt small induction furnace (SPB-CTF) comes with a jaw-dropping power rating of 15kw ~90kw. It can conveniently accommodate three distinctive furnace bodies simultaneously without any hiccups.

- IGBT induction technology is capable of reducing your power consumption by 15-30%. Compared the normal KGPS with higher power consumption rates; Saving you both money and energy.

- SuperbMelt small tilting melting furnace is designed with a motor drive chain tilting technology which improves your work efficiency and easy pouring of metals.

- With this furnace, tilting control becomes more flexible and also tilting speeds can easily be adjusted.

- You are guaranteed of a safer and precise control over your melting operations.

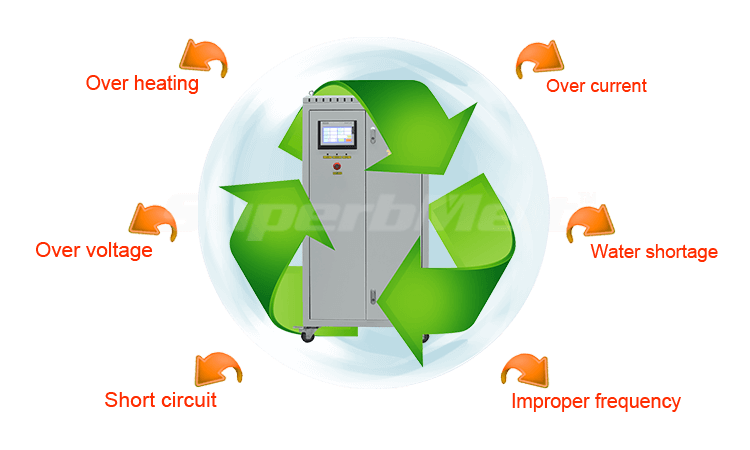

- This small tilting induction melting machine is also equipped with an omni-directional warning system that triggers when there is system; over-voltage, over-current, over-heating, short circuit, water shortage, improper frequency which may damage your equipment or pose serious explosion hazard to your workers.

Gone are the days when you waste so much time and energy in the bid to changing your furnace crucibles. Furnace crucible replacement is life made easy with this SuperbMelt small induction furnace (SPB-CTF). It gives the flexibility to replace your crucible in no time, thereby saving you so much energy and time.

Power Supply Parameter Of Chain Tilting Electric Induction Furnace

| Model | SPB-CTF-15 | SPB-CTF-25 | SPB-CTF-35 | SPB-CTF-45 | |

| MAX input power | 15KW | 25KW | 35KW | 45KW | |

| MAX input current | 23A | 36A | 51A | 68A | |

| Input voltage | Three-phase 340V ~420V 50/60Hz | ||||

| Oscillation frequency | 1K~20KHz | ||||

| Requirement of cooling water | Hydraulic pressure | ≥0.2Mpa | ≥0.3Mpa | ||

| Flow rate | ≥6L/Min | ≥20L/Min | |||

| Temperature of water | ≤45℃ | ||||

Melting Capacity Parameter Of Chain Tilting Melting Furnace

| Model | Fe, ss | Cu, Au, Ag | Al, Al-alloy |

| CMF-15 | 3kg | 10kg | 3kg |

| CMF-25 | 5kg | 20kg | 5kg |

| CMF-35 | 10kg | 30kg | 10kg |

| CMF-45 | 18kg | 50kg | 18kg |

| Remark: Above melting capacity sheet for general reference; Melting duration: When the crucible is hot,20~30min./workload; When the crucible is cold(first melt),40~50min./ workload. | |||

Graphite crucible for gold/Silver melting Furnace

Why SuperbMelt Small Induction Furnace

Helpful Resource For Your Reference ( An expert about SuperbMelt induction melting furnace )

More SuperbMelt Small Induction Furnaces For Your Choice

Any Question About SuperbMelt Small Induction Furnace

FAQ Guide of Small Induction Furnace

- Can I melt silver at home?

- Can you melt silver and gold together?

- How can impurities be removed from metals?

- Can you use borax as flux?

- Does induction heating work on stainless steel?

- How do you get gold from gold ore?

- Does molten copper stick to steel?

- How can I reduce the power consumption of my induction furnace?

- How do I calculate the efficiency of my furnace?

- How do you melt copper in a furnace?

- How do you melt gold dust?

- How do you melt iron?

- How do you melt metal in a furnace?

- How do you melt scrap metal?

- How do you safely melt metal?

- How do you smelt iron?

- How hot can induction heating get?

- Is it dangerous to melt aluminum?

- Is smelting bad for the environment?

- What are the advantages of electric heating over other types of heating?

- What is the difference between electric arc furnace and induction furnace?

- Why do you need an induction melting furnace?

- How to choose the induction melting furnace you need?

- How many important factors to consider when choosing when choosing the best induction melting furnace?

- How do I smelt gold dust, ores and mines to collect gold?

- Can you melt gold down to make jewelry?

- How do you get gold from gold ore?

- How do you get impurities out of gold?

- What is an induction furnace principle?

- How many types of induction furnaces can Superbmelt provide?

- How do you smelt gold jewelry?

Can I melt silver at home?

Yes, as long as you have the right equipment, you can easily melt your silver at home. Just make sure that you have the right protective gear, with a machine that can generate the right temperature. 1-2 mini silver melting furnace is the best for home applications due to its compact design and other fantastic features. Just take your time and get the best induction furnace for sale, that will get you the job done in the most convenient way possible.

Can you melt silver and gold together?

How can impurities be removed from metals?

For most uses of metals pure metal is required, but in nature, it is found with impurities. The process of separating metals from impurities is referred to as “refining”. This process leaves the metal in a pure state for commercial applications. The procedure can be achieved in some ways, the most common methods of refining are: refining by fire, by electrolytic or chemical method.

The simplest method of removing impurities from metals is to add flux to the metal and heat in a smelting equipment. Adding flux to impure metal leaves a clean metal behind while the impurities are contained in the slag that is easily removed.

Can you use borax as flux?

Does induction heating work on stainless steel?

Stainless still can be heated to attain a molten state. An induction furnace can produce enough heat energy and pressure to achieve the desired results. So the answer is yes.

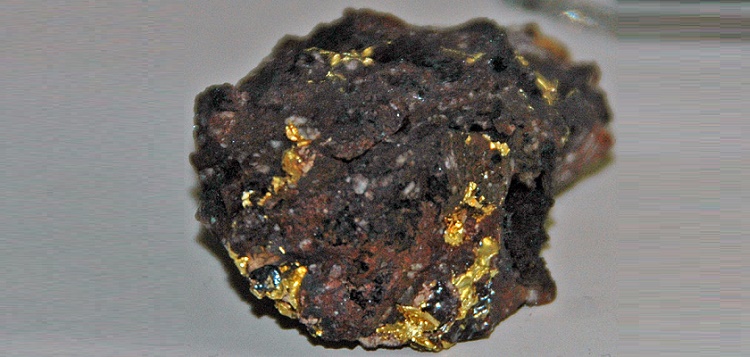

How do you get gold from gold ore?

The most common technique of getting gold from ore is the use of cyanide in various ways. In one, the ground ore is put in a tank containing a weak cyanide solution and zinc is added. The zinc causes a chemical reaction which separates the gold from its ore. The gold is then removed from the solution with a silver press.

Another method is the “carbon-in-pulp” method, for this method, the ground ore is mixed with water before cyanide is added. Then carbon is added to bond with the gold. The carbon gold particles are put into a caustic carbon solution, separating out the gold.

In heap-leaching, the ore is placed on open-air pads and the cyanide sprayed over it, taking several weeks to leach down to an impervious base. The solution then pours off the pad into a pond and is pumped from there to a recovery plant where the gold is recovered. Heap-leaching helps recover gold from ore that would otherwise be too expensive to process.

Does molten copper stick to steel?

Yes, which is why this might not be the best way to get a significant amount of copper, It does stick this way due to capillarity.

How can I reduce the power consumption of my induction furnace?

You can reduce the overall power consumption of your furnace by choosing the right power, the right capacity, the right operation, etc.

How do I calculate the efficiency of my furnace?

The work efficiency formula is efficiency = output / input, and you can multiply the result by 100 to get work efficiency as a percentage. This is used across different methods of measuring energy and work, whether it’s energy production or machine efficiency.

How do you melt copper in a furnace?

Use induction furnace because it can heat copper beyond its melting point and also maintain the heat. Place your copper into the crucible and turn on the furnace. Once the melting point is attained, you need to keep heating at a stable level until all the copper has become molten. SuperbMelt has you covered in case you are looking for induction furnace for sale.

How do you melt gold dust?

You need an electric furnace to melt your gold dust. Your furnace should be able to induce enough heat and temperature to melt your gold.

How do you melt iron?

You need an electrical melt furnace to melt iron. You will need to heat up to at least 1800 or 1900 degrees Celsius. Place your iron in a crucible and turn on the furnace.

How do you melt metal in a furnace?

Place your metal in a crucible and turn on the furnace. Depending on the metal you are melting, heat to the right temperature to let it melt.

How do you melt scrap metal?

Depending on the scrap type, separate them and then put them in different crucible that can fit all the pieces. Turn on your furnace and let the melting begin.

How do you safely melt metal?

To melt metals safely, you need to put on safety gear such as gloves, and face mask. Accidents might happen and you could get hurt when they do. You can also stay safe by ensuring that you choose the right supplier such as SuperbMelt. They have high quality stove with features put in place to ensure utmost safety of users.

How do you smelt iron?

Collect iron ore, find the right furnace and have it ready, prepare the charcoal, and then power on your induction furnace. Start smelting and stop when you have gotten the best smelted property. Since it starts at 0 heat, it starts off cooking slower, but when the heat has built up enough, it will smelt items much quicker. Applying a red stone current to the furnace will make the Induction Furnace continue to use power to heat up. At maximum heat, it takes 1 EU/t to maintain while idle.

How hot can induction heating get?

There are many types of induction furnaces. The amount of heat required depends on the type and amount of metal you are trying to melt. Some induction furnaces can go as high as 2400 degrees Celsius.

Is it dangerous to melt aluminum?

If you are trying to melt aluminum, make sure to have safety gears on. Also, the risk depends on what you are using to do the melting. You need to pick stoves from highly reputable suppliers such as SuperbMelt.

Is smelting bad for the environment?

No, smelting is only bad for the environment if you are using too much noise and emitting harmful substances to the environment.

What are the advantages of electric heating over other types of heating?

Electric heating is environmental friendly, safe, and does not consume too much energy compared to other methods.

What is the difference between electric arc furnace and induction furnace?

The induction furnace is heated faster and has higher thermal efficiency. The heat is generated in the furnace (liquid steel), so the heating speed is high. In the arc furnace, the heat of the arc after the material is cleared must be transferred to the molten steel through the slag, which is indirect heating.

Why do you need an induction melting furnace?

An induction furnace is an electrical furnace in which the heat is applied by induction heating of metal.

You need gold smelting equipment because of its many benefits, among which are; clean melting process, energy efficient furnace, well controllable melting parameters compared to other means of metal smelting, improved metallurgical function, oxidation loss is reduced. Since the gold smelting equipment makes use of no arc or combustion, the temperature of the material is not higher than what is needed to melt, therefore prevents material loss. Other benefits are:

Increased production efficiency such that the shorter time required for melting helps to improve production speed without affecting the quality of melting. This in turn reduces the cost of production.

How to choose the induction melting furnace you need?

There are important things to consider before choosing a smelting equipment that will meet your smelting needs.

Furnace capacity– Gold smelting equipment comes in a variety of designs and sizes. The wide array of options provide you with an opportunity to select the best furnace that will meet your needs. Induction furnaces are available in large capacities that can occupy 250kg of metals at once, there are also small furnaces that can occupy 1 to 4kg of metal at once.

Latest technology- Gold smelting equipments are a better improvement to gas furnaces. The industry has improved from the basic open furnaces to a more efficient induction heating coil. It is vital to choose a furnace with up to date technology that provides an easy to control melting system.

Energy efficiency– Energy efficiency is closely linked to power supply needs. Metals vary in their melting temperatures. For example, the melting point of steel is 1370 degree celsius, you need to choose a smelting equipment whose melting temperature is way above that of the metal you are melting. Additionally, the smelting equipment you choose should take less time to heat up. If the smelting equipment heats up very quickly, it reduces the time required to melt the metal. It not only saves energy but increases productivity.

How many important factors to consider when choosing when choosing the best induction melting furnace?

The following are the factors that should come to mind when choosing a smelting equipment:

Metal type– The metal you are going to be melting will contribute to the choice of your smelting equipment. Smelting equipment have different melting temperatures, hence, you should choose a furnace whose melting temperature is higher than the metal you are melting.

High quality furnace- Quality is an important consideration. Irrespective of the price, a high quality furnace will serve longer than a low quality one.

Size- The size of your melting will influence your choice of furnace. If your melting needs require only small material, then a small capacity furnace is the best for you. However, if you run a large mining business, an industrial size furnace is suitable for your needs.

Energy needs– Think about the energy needs your smelting equipment will require. There are different energy needs of induction furnaces from 15kw to 160kw.

Mode of molten metal removal- The mode of molten metal removal often has to do with the design of the smelting equipment. Some smelting equipment allows molten metal to be tilted for removal, others allow complete removal of the crucible.

Price- Consider the money in your pocket before you choose a furnace that will meet your needs.

Warranty- The kind of warranty the smelting equipment manufacturer offers you will go a long way in telling you the quality of the product. A trusted metal smelting equipment manufacturer will have no problems giving a substantial warranty offer.

Maintenance- As induction technology improves, advancements in smelting furnaces are being integrated into the metal smelting equipment. Invest in a smelting equipment that will allow for easy maintenance even at home.

Induction furnace noise level- Ensure that you choose a metal smelting equipment that has minimal to zero noise when in use. This means it should be as quiet as possible.

Compatibility: Ensure that your smelting equipment is compatible with the crucibles it will be used with.

How do I smelt gold dust, ores and mines to collect gold?

Smelting gold with a gold smelting equipment is not a complex task. Although a propane torch, electric furnace, gas furnace or coal furnace is alway used, these are considered the traditional method of smelting. There is a very high possibility that you lose some precious metals with these methods. Therefore, you should consider using a smelting equipment, which is a cost effective and clean method.

To smelt gold dust or ore, you need flux which is a combination of borax and sodium carbonate. All these are placed in a crucible and into the smelting equipment. The smelting equipment is heated up to allow the metal to melt. Aluminium chloride can be added when smelting gold dust.

The purpose of flux is to separate your gold from impurities. After smelting, the slag floats on top which is easily removable, leaving your gold at the base of the crucible.

Can you melt gold down to make jewelry?

Yes, gold can be melted to make an entirely new jewelry with the right equipment. Have in mind that there isn’t always enough weight in old gold, therefore, more material has to be added to make jewelry.

Yellow gold is by far the easiest gold to reuse into jewelry, rose gold can also be reused. White gold however has many other metals mixed with it like platinum and silver, which has to be refined before use.

Getting a jeweler to melt your gold into jewelry may be difficult but you can do it yourself.

How do you get gold from gold ore?

The most common technique of getting gold from ore is the use of cyanide in various ways. In one, the ground ore is put in a tank containing a weak cyanide solution and zinc is added. The zinc causes a chemical reaction which separates the gold from its ore. The gold is then removed from the solution with a silver press.

Another method is the “carbon-in-pulp” method, for this method, the ground ore is mixed with water before cyanide is added. Then carbon is added to bond with the gold. The carbon gold particles are put into a caustic carbon solution, separating out the gold.

In heap-leaching, the ore is placed on open-air pads and the cyanide sprayed over it, taking several weeks to leach down to an impervious base. The solution then pours off the pad into a pond and is pumped from there to a recovery plant where the gold is recovered. Heap-leaching helps recover gold from ore that would otherwise be too expensive to process.

How do you get impurities out of gold?

After gold has been extracted from its ore, it needs to be purified. The following are the most common methods of removing impurities from gold.

Miller process- The miller process is used to refine gold on a large scale, is able to refine gold to 99.95% purity. This technique includes passing chlorine gas through melted, unrefined gold, causing silver and other base metals to turn solid and float to the top from where they are skimmed off. The result is 98% pure gold, which is then electrolytically refined to remove platinum and palladium.

Wohlwill process- Another large scale process is the Wohlwill process that refines gold to 99.999% purity. This electrochemical process uses a 95% pure gold bar as an anode and small sheets of pure 24-karat gold as the cathode. A current is passed through the system, which uses chloroauric acid as an electrolyte; the pure gold collects on the cathode, which can then be melted down or processed.

Cupellation- This process involves treating ores under high temperatures to separate noble metals, such as gold and silver, from base metals. Base metals, such as copper, zinc and lead, will oxidize whereas noble metals will not. Cupellation involves melting ore at temperatures that exceed 960 degrees Celsius, at this temperature the base metals oxidize gold remain on top of the mixture.

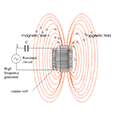

What is an induction furnace principle?

The principle of induction furnace is the induction heating: Induction heating is a form of non-contact heating for conductive materials. The principle of induction heating is based mainly on two phenomena: Electromagnetic induction and the joule effect.

Electromagnetic induction- The energy transfer to the metal to be heated occurs by means of electromagnetic induction. Any electrically conductive material placed in a variable magnetic field is the site of induced electric currents, called eddy currents, which will eventually lead to joule heating.

Joule heating- Joule heating, also known as ohmic heating and resistive heating, is the process by which the passage of an electric current through a conductor releases heat.

The heat produced is proportional to the square of the current multiplied by the electrical resistance (Q ∝ I2 ⋅ R).

Induction heating relies on the unique characteristics of radio frequency (RF) energy – that portion of the electromagnetic spectrum below infrared and microwave energy. Since heat is transferred to the product via electromagnetic waves, the part does not come into direct contact with any flame, hence, there is no product contamination.

An high voltage electrical source from a primary coil induces a low voltage, high current in the metal, or secondary magnetic core. Induction heating is simply a method of transferring heat energy. Induction furnaces are ideal for melting and alloying a wide variety of metals with minimum melt losses, however, little refining of the metal is possible.

How many types of induction furnaces can Superbmelt provide?

Superbmelt provides a series of smelting equipment to meet different categories of smelting needs. Below are the specific gold and silver smelting equipment we provide:

- Mini Induction melting furnace-The mini induction furnace is the smallest size of all Superbmelt induction melting furnaces. This smelting equipment is able to occupy between 1 to 2kg of metal at once. It is designed to melt precious metals and base metals. The power usage is 2.5kw to 3.8kw. Melting time with the mini furnace takes about two minutes and it is able to melt different batches continuously for 24 hours.

- Integrated induction melting furnace-The integrated induction melting furnace has a melting capacity of 3 to 5kg. The power requirement is between 15kw to 25kw. It is able to melt both ferrous and nonferrous metals. The melting time is usually 2 to 4 minutes and is able to melt continuously for 24 hours. The portable size makes it easy to transport.

- Stationary platinum induction melting furnace– The stationary platinum induction furnace adopts a medium frequency induction heating method to melt precious metals such as gold, platinum, palladium and their alloys. The melting temperature is 2800 degree celsius. It is able to melt up to 4kg metal capacity at once. The power required to melt is only 15kw.

- Integrated manual tilting induction melting furnace– The integrated tilting induction furnace is able to melt precious metals and their alloys of up to 10kg capacity. It is suitable for medium and large scale melting needs. The power required for melting is about 15kw. The furnace has a water cooling unit that enables it to melt continuously for long hours. The tilting furnace design makes it easy to remove molten metal. The melting temperature is 1800 degree celsius.

- Splited manual tilting induction melting furnace– The split manual tilting induction furnace is used for large industrial melting because it is able to melt between 20 to 30kg of precious and non-precious metals. The furnace has an omni-directional warning system that ensures safety during melting operation. The melting temperature is 1600 degree celsius. Its power requirement is between 25kw to 35kw.

- Chain tilting induction melting furnace– The chain tilt induction furnace is able to melt large batches of metals between 10kg to 50kg, which makes it suitable for industrial applications. The method of molten metal removal is easy. The smelting equipmentuses between 15kw to 45kw of power. The melting temperature is 1800 degree celsius.

- Motor tilting induction melting furnace-Motor tilting induction furnace is suitable for industrial applications because it is able to melt between 10kg and 100kg of metal. The power required for melting is between 15kw and 160kw. It is able to melt precious metals, base metals and their alloys.

- Hydraulic tilting induction melting furnace-The hydraulic tilting induction furnace can hold between 50kg to 250kg of metal at once, hence it is suitable for very large scale melting. It is able to melt precious and non-precious metals conveniently. The furnace is designed for easy removal of molten metal. The power it requires to melt is between 15kw to 160kw.

- Vacuum induction melting furnace– The vacuum induction furnace is mainly used to melt metals and alloys that have close affinity with oxygen and nitrogen. The melting capacity is between 1kg to 3kg. The power required for melting is 15kw.

How do you smelt gold jewelry?

To smelt gold, you need the appropriate equipment: Graphite or SIC crucible, tong, flux, protective gear, the metal you are smelting, gold has a melting point of 1064 degree celsius so you need a smelting equipment that can heat above 1064 degree celsius.

Flux is a substance that is mixed with gold before melting it. It is usually a mixture of borax and sodium carbonate. More flux is required if gold is impure. You can use different formulas for flux mixture. One method involves mixing borax and sodium carbonate. Add two pinches per ounce of clean jewelry scrap and more for jewelry scrap.

Flux helps hold together the fine gold particles and it helps remove impure materials from the gold as it heats. Your heating can be done in an electric furnace, a 1200 watt microwave or a smelting equipment.

You can decide what you will do with the smelted gold. Pour the molten metal in an ingold mold or any other mold before it solidifies.

Small Metal Induction Furnace for Sale

Both metal smelting and melting require constant supply of energy. While there are machines out there that could generate enough heat energy, they have flows. These drawbacks make them not reliable enough to be used where quality is desired.

At SuperbMelt, we do have many induction furnaces for sale, and that can make your melting and smelting dreams come true. We suggest that you read this piece in its entirety so that you learn how to use the small induction furnace. At the end of the main piece, we have included the steps you could use to get one.

Why Metals Need Melting: Small Metal Melting Machine in the Foundry Industry

There are different types of metals: ferrous and non-ferrous metals. They are used in different ways to make products. However, before that is done, they need to be melted. There are different reasons why metals need to be casted. We have explained some of them below. Keep reading and we will also help you pick the best induction furnace for sale.

1.1, Metal Melting To Remove Impurities

Metals that occur in natural ores mostly have impurities. In the foundry industry, there needs to be attained some level of purity before these metals are used to make crucial products.

For instance, Gold might contain impurities such as copper. Though precious to some extent, copper should be removed from gold to make it pure and valuable. Therefore, Gold will be melted to remove copper and other impurities.

Note that melting metals to remove impurities in molten state can be done in quite a number of ways. However, we do recommend small metal induction furnace since it does have benefits compared to other machines.

Aluminum, copper, silver, and many other metals can also be meted with small metal induction furnace to get rid of impurities. It is important to note that a metal is considered as an impurity if it occurs in an ore in which it is not needed.

To get metal to a molten state, you want to ensure that the right amount of heat is induced into the metal. Depending what you are trying to heat, make sure that you have the right temperature induced so that you do not struggle to remove impurities.

1.2, Metal Melting To Make Alloy

The foundry industry is a vast one. It entails lots of metal-work intended to make unique items. Some of these products are used to enhance the functionality of parts of machine, while some are used to make jewelries.

The problem, however, is that when metal alloys are needed, it cannot be found occurring naturally, unless they are just impurities. Therefore, the only best ways to make metal alloys is by using heat energy.

Once metal has been gotten into its molten state, mixing it with other metals becomes easier. It is a way of enhancing the overall quality and non-ferrous metals, more so when a unique products needs to be made.

Metal melting to make alloys is something that has been there for ages. However, the difference is the machines used to attain the best results. Small metal induction furnace, for instance, is one of the best machines that can be used to get ant metal to its molten state for easier alloying.

This machine provides the best conditions that are required for all types of ferrous and non-ferrous metals. Kindly consider talking to us at SuperbMelt so that you learn more about how you can benefit from our products and or services.

1.3, Melting Metal For Industrial Casting

This is the largest industries in which metal melting happens most. Like aforementioned, industries need to ensure that they have the best machinery parts. Some of them also want to stand out from the competition.

All these have been made possible thanks to metal melting furnaces. SuperbMelt has one of the best designed furnaces to ensure that your industrial metal melting dreams come true.

To get the best metal alloy for industrial casting reasons, you want to have the best quality of both metals. Whether you are looking for an aluminum-copper alloy, you need to start by making them pure, which can also be done through melting.

Once you are done removing impurities from your metals, you can heat them together by inducing the right levels of energy, As a reminder, you need to supply the right levels of energy so that you get a perfectly amalgamated product.

If you feel green on this, you can always get in touch with us. Let us keep learning more about small metal induction furnace.

How to Melt Different Kinds of Metals Nowadays

Metals are melted differently, depending on their physical and chemical properties. Let us look at some of them in this section. You will be using different types of melting furnaces to achieve your end results. Once you have found your most preferred induction furnace for sale, here is what you can use it for.

2.1, Precious Metal Melting Furnaces

There are several melting furnaces such as induction furnace, resistance furnace, and propane combustion. Even with that, you can do a lot more with induction furnace, and we have highlighted some of its benefits below. The tips can also help you find the best induction furnace for sale.

- Less melting and smelting time

- Does not consume a lot of energy

- Comes in compact design for easy operation

- Has a cooling system, hence can operate for 24 hours nonstop

- Can induce high temperatures for melting all sorts of metals

If you are looking for a compact designed and industrial friendly induction furnace for sale, you can always get in touch with SuperbMelt.

2.2, Iron & Steel Melting Furnaces

Melting furnaces are ideal for subjecting hard metals under high heat energies. Most of them leverage thermal processing equipment to let the users alter the internal characteristics of metals. They do this by changing the temperatures carefully.

As for the metals, this process enhances the overall ductility when exposed to both strength and hardness. To do this, you will need to get an industrial furnace that is capable of inducing and keeping the temperatures below that of the melting point of the metal.

In the current time, almost only induction furnaces are used for melting steel and Iron. Due to its unique and easily applicable features, induction furnace is highly reliable. We have also highlighted its benefits in the initial parts of this piece. For recap, you will like the fact that it is easily affordable and convenient for both small scale and large scale melting needs.

Therefore, go ahead and get in touch with us for top-quality induction furnace for sale. Take a look at our website and learn how you can acquire and benefit from our high-end yet easily affordable products.

2.3, Copper Melting Furnaces

Just like steel & iron melting furnaces, you can get the right furnace to melt copper. The only challenge is that there are quite some of them, and making the right choice might be a huge challenge. Therefore, you need to ensure that you have the right items in place.

Currently, the best methods to melt copper include induction furnace, resistance furnace, centralized insulation melting furnace and many other furnaces. At SuperbMelt, we have always encouraged our clients to go for induction furnace for melting copper.

Induction furnace might not be the best device on the market, but it can meet all your copper melting and smelting needs in the most convenient way. For instance, if you have a large production firm, you will run your induction furnace for 24 hours nonstop. It has a cooling system that keeps it going for long hours.

2.4, Aluminum & Lead Melting Furnaces

Aluminum & Lead melting furnaces are available for both small scale and large scale melting purposes. They do have different features such as maximum heat and pressure generated, and the amount of electric energy consumed.

Depending on the scale of production, you ought to pick something that would work for you within the shortest time possible. But this should also depend on your budget as a company.

It is possible to use things such as resistance furnace, induction furnace, centralized induction furnace, and many more. The choices are many, but they do not work in the same way, more so in terms of quality.

In your case, you need to try induction furnace. We understand that you can still use other furnace, but what if you need something that would work much faster? Induction furnace will not even produce bad elements to the environment, which makes it safe for workplaces. Induction furnace will also take enough space to let you do many other things in the company.

Types of SuperbMelt’s Metal Induction Furnaces for Sale

We are a furnace manufacturing company, and you can always get the best quality from us. If you have been wondering which are the best machines, you can get from us? We have highlighted them below.

We believe that after going through this bit, you will not struggle to find the best metal melting furnace to invest in.

3.1, Mini 1-2kg Induction Furnace for Sale

SuperbMelt mini metal melting furnace (SPB-DH) is suitable for any of your small-scale production. It is capable of melting any metal piece whose weight falls in the range 1-2Kg.

This small metal melting machine can, in no time, reach a maximum temperature of 1600℃. These features also make this machine for melting other metals. Metals such as silver, copper, and aluminum, just to mention a few.

SuperbMelt mini metal melting furnace also finds application in jewellery recycling. It also very suitable for precious metal diggers in deals in collecting gold and its alloys.

The mini metal melting furnace takes a minimum of two minutes to melt a batch of two kilograms of any precious metal. This sums up to producing approximately 30kg of metal in an hour.

Also, this electric gold melting furnace can work for 24 hours, none stop. At the same providing you with excellent services and efficient metal melting process.

SuperbMelt electric small melting furnace uses the latest IGBT induction technology. This technology reduces your power consumption and improves your production efficiency. This mini gold melting machine speeds up your melting processes. This serves as it’s competitive over any other furnace in the market.

It comes with video tutorials and installation guide. This makes installation on other operations very simple and easy to go about. Make sure that you can in touch with credible dealers in induction furnace for sale.

SuperbMelt mini gold melting equipment is environment-friendly. It comes with the latest inbuilt green technology, which is now being employed in the precious metal industry. It does not produce harmful gas and fumes which are associated with other gold melting furnaces.

This mini furnace is designed very simple and easy to use. Compact and small-sized as compared with other furnaces that take a lot of space

SuperbMelt mini metal melting furnace (SPB-DH) is the first choice for the jewelry foundry, the gold recovery plant, and the gold miner.

3.2, Integrated 3-10 Kg Induction Furnace for Sale

The gold melting furnace is designed for melting 1g – 10kg metal. It is also suitable to melt other precious metals like silver, copper, palladium.

The induction metal melting furnace is based on the latest and most advanced IGBT induction technology. The top speedy melting could be realized within 2-4 minutes. The crucible is extractable by means of the matched tong.

Superb gold melting furnace is the better choice for lab, jewelry shop, research institute, and mining company comparing with gas melting device and resistance melting type.

We will make testing videos for each machine to ensure quality. Superbmelt also provides warranty of a full refund due to bad quality within one year.

Energy saving, Environmental protection, Low pollution level and light weight, Economic Space Occupation. It comes in a design that encourages easy installation.

Enhanced monitoring and diagnostics system of SPB-H series gold melting furnace, guarantee the machine of high stability, reliability and security.

Strict Supplier Management System and ISO 9001:2015; CE Quality Management System guarantee high quality of each equipment. 100% duty cycle , 24hours continuous working ability at maximum power due to elaborate cooling system, unlike other furnaces.

This Superb gold melting furnace takes Use of solid-state IGBT inverter and power regulation, soft switch three resonance and frequency automatic tracking technology.

The top speedy melting rate can finish per batch within 3 mins nearly, which makes it ideal for large scale application.

3.3, 1-4kg Platinum Induction Furnace for Sale

SuperbMelt platinum melting furnace (SPB-B) is a totally ingenious technological creation which is designed with the aim of providing superior melting action on precious metals like platinum, gold, palladium or alloys of these metals.

This platinum smelting furnace can reach a temperature of about 2600℃ (It is about 900℃ higher than the platinum melting point.) in no time. This is suitable for melting metals (which may be in any form such as solid, dust, scrap, ingot or powder) weighing between 1kg and 4kg in a record time of less than 5 minutes.

SuperbMelt platinum melting furnace is your best bet if you run a scrap metal refinery business or an old jewelry refining plant. This furnace is just the machine you need to boost your production and overall efficiency.

Superbmelt platinum and gold melting equipment ensures the homogeneity of the melted or liquefied metal. This is achievable through the incorporation of a strong electromagnetic stirring system. This eliminates the inconvenience of having uneven surfaces especially in alloys.

An omni-bearing security alert readily warns the operator(s) when the system is being run under potentially harmful conditions. Conditions such as overheating, short-circuit, unduly high current or low water levels can easily be detected

You can be rest assured that personnel safety has not been compromised for efficiency in the design and development of this furnace.

SuperbMelt platinum melting equipment also comes with an inherent water pump. This strikes the need for additional pumps. Thereby saving you more money

The operation process is intuitive. An average furnace operator should not have any difficulty whatever in understanding and getting used to the working of the furnace.

SuperbMelt platinum melting furnace (SPB-B) is economical both in weight and volume. This makes it very easy to haul.

This product is compact and small sized. It will give more room for other equipment’s in your plant.

A combination of low noise operation, low carbon foot print and the durability of

working for 24 hours ensures that you can achieve your profit targets while still being environmentally responsible.

A total adherence to the supplier management system and the ISO 9001 2015 CE quality standards makes this platinum melting furnace the best choice for your foundry or laboratory.

3.4, 20-30kg Manual Tilting Induction Furnace for Sale

SuperbMelt gold melting equipment (SPB-TB) can reach a maximum temperature of 1800℃ (the max temperature of tilting platinum smelter is 2600℃) with a power rating of 25kw. This provides an ultra-high heating effect capable of melting either 80kg of gold,silver (and similarly commensurate weights of other metals) within a period of 10-15 minutes.

SuperbMelt platinum and gold smelting equipment can heat your raw metals very fast. It speeds up your operations with the ultimate effect of increasing the profit margin. The gold melting machine is suitable for jewelry foundry and old jewelry refining plants.

Based on advanced IGBT induction technology, the gold smelting equipment is highly effective gold smelting solution. It has come to be trusted by operators and business owners alike over time due to its superior action which is.

Designed with convenience and efficiency as the core targets.

The tilting furnace design ensures that melted metals can easily be poured into the mold. This prevents spillage or splashing which reduces the risk of operator injuries from hot liquid metal splashes.

Another proof of the commitment to operator convenience is the use of a replaceable crucible for easy maintenance.

Also, a strong electromagnetic stirring system ensures homogeneity of the liquefied metal. This comes handy, especially for alloys.

The gold smelting furnace is also equipped with an omni-directional warning system. This alerts the operator when potentially harmful operating conditions are being approached.

Induction gold smelting kit is manufactured with the capability of operating at full capacity for 24 hours. This considerably lowers downtime except for scheduled maintenance.

The use of induction technology presents an advantage. Owing to the absence of electrodes and electric arcs, which can form deposits of impurities.

Finally, no combustion takes place thereby preventing the production of unsafe gases like oxides of carbon and nitrogen. The induction gold melting equipment has an edge over other forms of furnace. Resistance and gas furnace often gives off some gases that are unsafe for the environment.

3.5, 10-50 Kg Chain Tilting Induction Furnace for Sale

A small induction Furnace, capable of melting almost any metal of choice. SuperbMelt small induction furnace (SPB-MF) comes with a jaw-dropping power rating of 15kw ~90kw. It can conveniently accommodate three distinctive furnace bodies simultaneously without any hiccups.Therefore, you need to consider it when looking for the best induction furnace for sale

IGBT induction technology is capable of reducing power consumption by 15-30%. Compared the normal KGPS with higher power consumption rates; Saving you both money and energy.

SuperbMelt small tilting melting furnace is designed with a motor drive chain titling technology, which improves your work efficiency and easy pouring of metals. With this furnace, titling control becomes more flexible and also titling speeds can easily be adjusted.

You are guaranteed of a safer and precise control over your melting operations. This small tilting induction melting machine is also equipped with an omnidirectional warning system that triggers when there is system; over-voltage, over-current, over-heating, short circuit, water shortage, an improper frequency which may damage your equipment or pose serious explosion hazard to your workers.

Gone are the days when you waste so much time and energy in the bid to changing your furnace crucibles. Furnace crucible replacement is life made easy with this SuperbMelt small induction furnace (SPB-MF). It gives the flexibility to replace your crucible in no time, thereby saving you so much energy and time.

3.6, 10-100 Kg Motor Tilting Induction Furnace for Sale

This motor tilting induction metal melting furnace is designed for 10-80kg ferrous and non-ferrous metal melting based on induction technology.

SuperbMelt metal melting furnace is constructed for one-man pouring action. Its body is mounted onto a steel frame. By manual control, the furnace body can be set in any position when tilting.

According to ferrous melting or non-ferrous melting, the crucibles will be taken use of different materials. Graphite crucible is special for non ferrous metal like copper, gold, silver, aluminum. Silicon crucible is suitable for ferrous metal.

The small land occupied, fast melting and energy-saving are its obvious features. That is the cost performance choice for metal casting with small capacity.

Medium frequency metal melting furnace can be used for the melting of gold, silver, steel, stainless steel, brass, aluminium, lead, zinc and so on. Your search for induction furnace for sale will end as long as you secure this highly aggressive, reliable machine.

Comparing with SCR/KGPS technology, IGBT technology can save 15%-30% energy and is much more efficient than gas-fired and coal-fired method.

Small light, a lot of models can be selected to melt different amount of metals. Not only is it suitable for the factory, but also suitable for the college researching companies to use.

The crucible replacement is very easy for different metal material.The occupied land for the induction metal melting furnace is less than 1 square meter.

Modular design, ease of maintenance, no need to repair any special foundations, requires low operation cost, easily operable, produces no pollution and noise. 24 hours constant working will meet your long time melting. Contact SuperbMelt if you have been looking for highly reliable induction furnace for sale like this one.

3.7, 50-250 Kg Hydraulic Tilting Induction Furnace for Sale

SuperbMelt Electric Induction Furnace (SPB-HMF) comes from one of a leading induction furnace manufacturer in Asia. It is capable of melting any ferrous and non-ferrous metals such as gold, silver, copper, zinc, aluminium, steel and lead. Minimum and maximum weight requirement of 50Kg and 250kg respectively are considered suitable benefit from an output power rating of 45kw ~160kw.

The Electric Induction Furnace is incorporated with a Simens controls system (PLC). This gives accuracy, precision and better control to your melting process.

The electric induction melting furnace gives the flexibility to melt different kinds of metals with just a single furnace; a feature which saves you a lot of money.

This induction metal melting furnace is crucibles are quite convenient and super fast to replace. This also saves you energy and speeds up your melting process.

As compared with the regular KGPS furnace and electric arc furnace, the SuperbMelt IGBT technology reduces your power consumption by 15-30% at while working at optimum capacity.

It also comes with a hydraulic tilting design which can be controlled with the aid of a remote panel trolley. The control system ensures that you do not go overboard with any of your input and output parameters. This feature guarantees the safety of you and your staff.

The omni-directional warning system ensures that you do not experience any form of system malfunction. Malfunctions such as system over-voltage, over-current, over-heating, short circuit and water shortage can easily be eliminated.

The induction melting machine can be operated continuously for 24hours. No room for downtime with this product.

This product also comes with a magnet yoke. This yoke improves your melting efficiency, thereby saving you more energy. With all the features and benefits mentioned above you tend to save more money. You’ll achieve more stability with your operations. Your work efficiency will be greatly increased. In short, your operators’ safety is guaranteed.

Conclusion: How to Choose The Right Induction Metal Melting Furnace

Are you planning to invest in a melting furnace? You are in the right place. At SuperbMelt, we have inevitable deals for those looking for induction furnace for sale, depending on the factors you consider most while creating your budget.

4.1, Choose the Right Capacity

If you are looking to invest in a melting furnace, at least make sure that you pick the right capacity depending on the amount of metal you will be melting each time of application.

4.2, Pick The Right Furnace

You can choose among induction furnaces, resistance furnace, and a centralized holding furnace. However, if you are looking for quality and most pleasurable applications, then induction furnace is the best. It also works within a short duration, with a perfect cooling system. Find out if your preferred dealer has the best induction furnace for sale that will meet all your needs.

4.3, Important Factors to Consider When Picking The Best Metal Melting Furnace Efficiency

You need a melting furnace that would work seamlessly for the entire period of application.

Safety

Talking about safety, some furnaces get really hot and could explode due to a lack of elaborate cooling systems. These might not be the best machines to use for melting metals.

Easy Installation

These melting machines have parts. These parts can be easy or complicated, or they can be delicate or durable. It is advisable to pick one with parts that are easy to install, depending on the original design.

Technology

Machines come in different designs and enhancements to make work easier. However, there are still those that work better than the rest. A good example is the induction furnace from SuperbMelt.

Cost

Plan ahead and know the amount of money you are willing to spend on a new item. Note that in some cases, quality can be determined depending on the price of the machine you are buying. You should not spend an arm and leg trying to find the best induction furnace for sale.

Compatibility

If you intend to use a melting machine along with other applications, or you have a unique way of producing outputs, make sure to get a melting machine that matches your line of operation.

Environmentally Friendly

Noise and substance emission are some of the things that have negative impacts on the environment. You need a machine that operates silently and does not produce any substance into the environment.

Warranty

A good manufacturer is one that is confident in the quality of the products that they sell. Therefore, they need to provide a warranty to their customers, especially ones who are using the products for the first time.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited