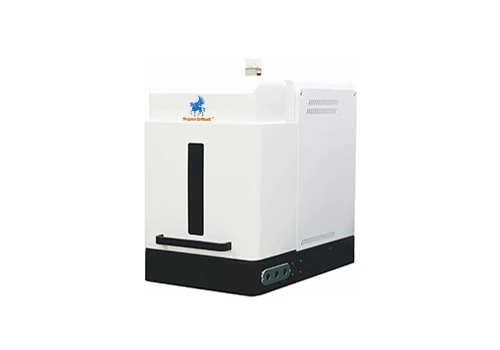

Gold Laser Marking Machine

SuperbMelt gold engraving machine is an essential tool for jewelry engraving craftsmanship

Gold Laser Marking Machines are specifically designed for marking, engraving, or etching designs, text, logos, or patterns on gold and other precious metals. These machines create artistic engravings for luxury gold items or collectibles and are widely used in the jewelry industry, high-end manufacturing, and luxury brand sectors due to their precision and reliability.

Using laser technology, these machines can create permanent and detailed markings without physical contact with the surface, ensuring high accuracy and minimal material loss, which helps reduce costs for businesses.

SuperbMelt offers a variety of Gold Laser Marking Machines ranging from 20W to 50W to meet the diverse needs of businesses. For more details, contact SuperbMelt today!

| Type: | Mini Laser Engraving Machine For Metal |  |

| Model Number: | FLMM-series | |

| Laser power: | 20W/30W/50W | |

| Marking range: | 100mm×100mm | |

| Marking speed: | ≤10000mm/s | |

| Power supply: | AC220V±10%/50Hz | |

| Cooling method: | Air-cooled | |

| Positioning method: | Red ray positioning | |

| Accessibility: | 3 red ray assisted focus | |

| Lifting stroke: | 250mm |

Features:

- High Precision: The machine boasts outstanding engraving precision, ensuring detailed and accurate results.

- Multi-functionality: It’s a versatile tool, capable of engraving various designs, patterns, and text, making it suitable for a wide range of applications.

- Ease of Customization: The machine allows for personalized and customized designs, catering to different industry needs.

- User-Friendly Operation: Designed for user-friendliness, even individuals new to laser engraving can easily operate it.

- Broad Material Compatibility: It can mark and engrave on various materials, including metals, wood, leather, textiles, and more.

Advantages:

- High-Quality Engraving: Ensures high-quality and visually appealing engravings on jewelry and other items.

- Durable and Long-lasting: The machine is known for its durability and long-term performance, offering reliability for various applications.

- Increased Aesthetics: Enhances the visual appeal of jewelry and other products, adding value to the finished items.

- Efficiency: The machine’s fast operation speeds contribute to increased productivity, making it an ideal choice for industries with high engraving demands.

- Versatility: With its ability to work on a wide range of materials, it serves as a flexible tool for diverse industries.

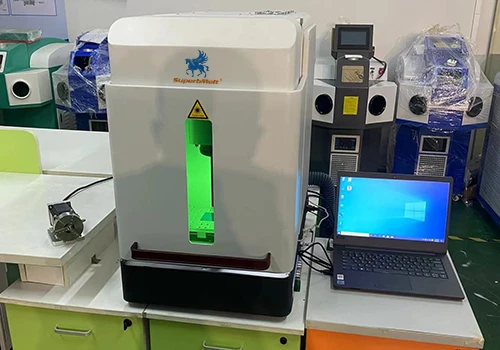

Laser Jewelry Engraving Machine Marking Table

Desktop laser switch starter

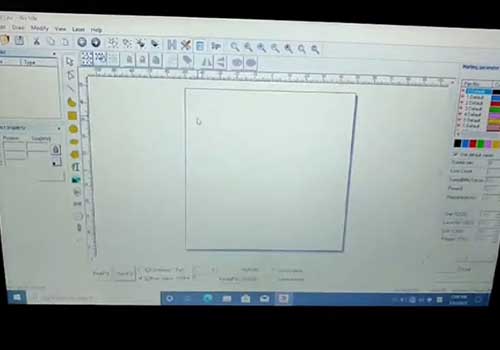

The small jewelry laser engraving machine can handle three file formats: DXF, TLP, and AI for printing.

Why SuperbMelt Gold Laser Marking Machine

Any Question About SuperbMelt Gold Laser Marking Machine

FAQ Guide of Gold Laser Marking Machine

- 1. Which laser machine is best for gold jewellery engraving?

- 2. What is the difference between laser marking and laser etching?

- 3. Can you laser engrave jewellery?

- 4. Can sterling silver be laser engraved?

- 5. Can you laser engrave gemstones?

- 6. Does laser engraving on metal wear off?

- 7. Do you need to passivate after laser marking?

- 8. Is there a warranty or support available for this machine?

- 9. Can this machine handle batch production?

- 10. Is training required to operate this machine?

1. Which laser machine is best for gold jewellery engraving?

The best laser machine for gold jewelry engraving is typically a Fiber Laser Marking Machine. This type of laser machine is widely preferred due to its precision, speed, and ability to engrave intricate designs on delicate materials like gold. Below are some key features that make fiber lasers ideal for gold jewelry engraving:

1. High Precision

- Fiber lasers can engrave detailed patterns, logos, or text with exceptional accuracy, which is crucial for fine gold jewelry.

2. Non-Contact Marking

- The laser beam does not physically touch the jewelry, preventing surface damage or distortion.

3. Minimal Material Loss

- Fiber lasers remove only a tiny layer of gold during engraving, preserving the material.

4. Speed and Efficiency

- These machines can engrave at high speeds, improving production efficiency without sacrificing quality.

5. Durable and Permanent Marks

- Fiber lasers create lasting engravings that won’t fade or wear off over time.

6. Versatility

- Suitable for engraving various shapes and sizes of jewelry, including rings, pendants, bracelets, and more.

Recommended Machine:

SuperbMelt Fiber Laser Marking Machine

SuperbMelt offers a range of laser machines with customizable power options (e.g., 20W, 30W, 50W) to suit your specific jewelry engraving needs. These machines are user-friendly, highly efficient, and designed for long-term performance.

For more information on the best laser engraving machines for gold jewelry, contact SuperbMelt today!

2. What is the difference between laser marking and laser etching?

The main difference between laser marking and laser etching lies in the depth of material modification and the process used to create the mark:

1. Laser Marking

- Process: Alters the material’s surface without removing any material. It creates marks through oxidation, discoloration, or annealing.

- Depth: Superficial (no significant material removal).

- Appearance: Produces high-contrast, smooth marks, often in black or white.

- Applications:

- Ideal for barcodes, serial numbers, logos, and text.

- Commonly used on metals, plastics, and ceramics.

- Advantages:

- Non-invasive and maintains the material’s integrity.

- Excellent for applications where surface smoothness is critical.

2. Laser Etching

- Process: Uses a laser to melt the material’s surface, causing it to expand and form a slightly raised mark.

- Depth: Penetrates deeper than marking but is shallower than engraving.

- Appearance: Creates a textured, raised mark with high durability.

- Applications:

- Often used for decorative purposes, part numbers, or industrial marking.

- Works on metals, plastics, and coated surfaces.

- Advantages:

- Faster than engraving.

- Creates durable and visible marks suitable for moderate wear.

Key Differences:

| Aspect | Laser Marking | Laser Etching |

|---|---|---|

| Material Removal | None | Slight material removal |

| Depth | Very shallow | Shallow (slightly raised) |

| Durability | High (depends on process) | Higher than marking |

| Use Case | Identification and traceability | Decoration or moderate wear marks |

Conclusion:

- Choose Laser Marking if you need a smooth, non-invasive, high-contrast mark for identification or branding.

- Choose Laser Etching for applications requiring slightly textured, durable marks that stand out more visually.

3. Can you laser engrave jewellery?

Yes, jewelry can be laser engraved. Laser engraving is a precise and versatile method to create detailed and permanent designs, patterns, text, or logos on various types of jewelry made from metals like gold, silver, platinum, and stainless steel. It is commonly used for personalizing jewelry, adding intricate details, or creating brand logos on high-end pieces.

Benefits of Laser Engraving for Jewelry:

- High Precision: Laser engraving allows for highly detailed and intricate designs that are impossible with traditional engraving methods.

- Durability: The engraving is permanent and resistant to wear, ensuring longevity.

- Versatility: Suitable for various materials, including precious metals, gemstones, and even non-metallic surfaces like wood or acrylic used in mixed-material jewelry.

- Speed: Laser engraving is faster than traditional methods, making it ideal for mass production or time-sensitive customization.

- No Contact Process: Reduces the risk of damaging delicate jewelry pieces.

Common Applications:

- Personalization: Names, initials, special dates, or messages.

- Branding: Logos or insignias for jewelry designers and manufacturers.

- Design Enhancements: Decorative patterns or textures.

- Serial Numbers: For tracking or certification purposes in high-value items.

Laser engraving has become a standard practice in the jewelry industry due to its accuracy, efficiency, and ability to cater to both personal and commercial needs.

4. Can sterling silver be laser engraved?

Yes, sterling silver can be laser engraved. Laser engraving is an ideal method for creating intricate and permanent designs, text, or logos on sterling silver due to its precision and efficiency. Sterling silver, composed of 92.5% silver and 7.5% other metals (usually copper), is a durable material that responds well to laser engraving.

Why Laser Engrave Sterling Silver?

- High Precision: Laser engraving allows for detailed and intricate designs, making it perfect for personalization or decorative elements.

- Durable Markings: The engraving is permanent and does not wear off easily, ensuring long-lasting results.

- Minimal Material Loss: Laser engraving is a non-contact process, reducing the risk of damaging the silver surface or wasting material.

- Versatility: Suitable for a variety of applications, such as jewelry, commemorative items, and customized gifts.

- Aesthetic Appeal: Laser engraving creates clean and sharp markings that enhance the overall appearance of the item.

Applications:

- Personalized Jewelry: Names, dates, or meaningful messages on rings, necklaces, or bracelets.

- Corporate Branding: Logos or promotional designs on silver products.

- Luxury Items: High-end silverware or accessories with decorative patterns.

- Awards & Keepsakes: Customized plaques or trophies.

Sterling silver’s smooth and reflective surface makes it particularly suitable for laser engraving, ensuring the designs are highly visible and aesthetically pleasing.

5. Can you laser engrave gemstones?

Yes, gemstones can be laser engraved, but the feasibility depends on the type of gemstone and the engraving method. Laser engraving is commonly used on harder, durable gemstones, such as diamonds, quartz, and sapphires. The laser precisely etches designs, text, or patterns on the gemstone’s surface without requiring physical contact.

Key Considerations for Laser Engraving Gemstones:

Type of Gemstone:

- Hard Gemstones (e.g., diamonds, rubies, sapphires): Can withstand the high heat of a laser and are ideal for engraving.

- Soft or Porous Gemstones (e.g., turquoise, opals, pearls): More delicate and may require specialized techniques or lower laser power to avoid damage.

Engraving Purpose:

- Personalization: Adding names, dates, or unique designs to jewelry.

- Branding: Engraving logos or identification marks.

- Security: Unique identifiers, especially on diamonds, for certification and tracking purposes.

Engraving Depth:

- Shallow surface markings are common to avoid compromising the gemstone’s structural integrity.

- Deep engravings might not be suitable for all gemstones due to the risk of cracking or weakening.

Laser Type:

- Fiber Lasers: Effective for hard gemstones like diamonds.

- CO2 Lasers: Often used for softer materials but are less commonly employed on gemstones due to their lower intensity.

Advantages of Laser Engraving Gemstones:

- Precision: Achieves intricate and fine details that are hard to replicate with traditional methods.

- Durability: The markings are permanent and resistant to wear.

- Non-Invasive: No direct contact with the gemstone minimizes the risk of physical damage.

- Versatility: Works on various shapes and sizes of gemstones.

Applications:

- Jewelry Personalization: Rings, pendants, or bracelets with custom designs.

- Diamond Inscription: Unique identifiers or certification marks on diamond girdles.

- High-End Branding: Logos or artistic engravings on gemstone pieces.

- Commemorative Items: Special occasions or gifts marked with meaningful messages.

While laser engraving gemstones requires specialized equipment and expertise, it offers unmatched precision and aesthetic quality for enhancing or personalizing gemstone jewelry.

6. Does laser engraving on metal wear off?

Laser engraving on metal does not easily wear off because it creates permanent markings by altering the metal’s surface. The durability depends on the engraving technique and the type of metal. Here’s an explanation:

Why Laser Engraving on Metal is Durable

Permanent Markings: Laser engraving melts or vaporizes the top layer of the metal, creating an etching or mark that is physically part of the material.

- Unlike surface coatings like paint, engraving doesn’t chip or peel.

Resistant to Wear: Laser-engraved markings are highly resistant to:

- Scratching: Engravings are often recessed, making them difficult to damage through abrasion.

- Fading: Since no ink or dye is used, there’s nothing to fade or discolor.

- Environmental Exposure: They can withstand high temperatures, moisture, and corrosion.

Metal Type: Some metals, like stainless steel or titanium, retain engravings better than softer metals like aluminum.

Situations Where Wear Might Occur

- Heavy Abrasion: Repeated friction (e.g., rubbing against other objects) can erode shallow engravings over time.

- Corrosive Environments: If the metal itself corrodes, the engraving might degrade along with the material.

- Shallow Marking Depth: Laser etching (lighter, surface-level marking) can wear off faster than deeper engraving.

How to Ensure Longevity

- Choose the Right Laser Power: For industrial or jewelry applications, deeper engravings last longer than shallow ones.

- Select Durable Metals: Harder metals are better for permanent engravings.

- Apply Protective Coatings: A clear coating can protect against harsh environments without obscuring the engraving.

In conclusion, laser engraving on metal is highly durable and resistant to wear under normal conditions, making it a preferred method for creating long-lasting marks on jewelry, tools, and industrial equipment.

7. Do you need to passivate after laser marking?

Passivation after laser marking is sometimes necessary, depending on the material being marked and its intended application. Passivation is a chemical process that removes contaminants and enhances the corrosion resistance of metals, especially stainless steel. Here’s a detailed explanation:

When to Passivate After Laser Marking

Marking Stainless Steel:

- Laser marking can expose free iron or other impurities on the surface of stainless steel.

- Passivation removes these impurities, preventing rust and preserving the steel’s corrosion resistance.

Applications in Harsh Environments:

- For items exposed to moisture, chemicals, or extreme conditions (e.g., medical tools, marine equipment), passivation ensures durability.

Compliance with Standards:

- Industries such as medical, aerospace, and food processing often require passivation to meet strict regulatory standards.

When Passivation May Not Be Necessary

- Non-Corrosive Environments:

- If the marked item is used indoors or in dry environments, passivation might not be needed.

- Certain Laser Marking Techniques:

- Advanced marking methods, like annealing, do not remove surface material and leave the metal’s protective oxide layer intact, reducing the need for passivation.

How Passivation Works

- The process typically involves immersing the item in a solution like nitric acid or citric acid.

- This removes free iron and other contaminants, allowing a protective chromium oxide layer to form naturally on the surface.

Advantages of Post-Laser Marking Passivation

- Enhanced corrosion resistance.

- Removal of potential contaminants.

- Compliance with industry standards (e.g., ASTM A967 or ISO 16048).

Conclusion

Passivation after laser marking is recommended for stainless steel and applications requiring high corrosion resistance. For other metals or controlled environments, it may not be necessary, but consulting with material specifications and application requirements is key.

8. Is there a warranty or support available for this machine?

SuperbMelt typically provides warranty and customer support for their machines. Please refer to the manufacturer for specific details.

9. Can this machine handle batch production?

Yes, it is suitable for batch production in jewelry and other industries, offering efficiency and consistency.

10. Is training required to operate this machine?

Basic training is recommended to understand the machine’s functions and capabilities. SuperbMelt may offer training or guidance.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited