Stone Automatic Glue Dispensing and Setting Machine

SuperbMelt Jewelry Glue Dispensing and Stone Setting Machine can complete 6,000 stones per hour.

SuperbMelt Stone Automatic Glue Dispensing/Setting Machine completes glue dispensing and stone setting for 6,000 stones per hour, making it suitable for various jewelry and hardware craft applications.

This machine features a five-axis linkage workbench with 360-degree rotation, supporting flat, three-dimensional, large-angle, and large-arc designs for jewelry or other hardware crafts.

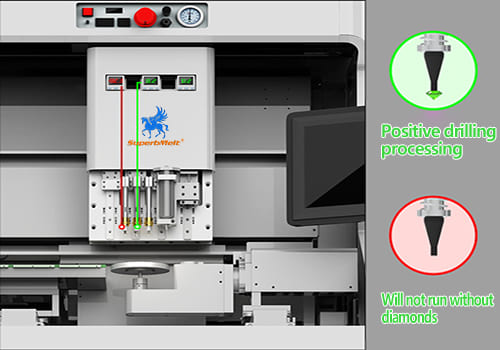

- High-precision glue dispensing and stone setting, ensuring no damage to the product or stones with stable output paths.

- Automatically detects empty slots, skips unfilled slots, and automatically fills any missed ones.

| Equipment nam | Stone Dispensing Setting Machine |

| Equipment Model | SPB-5DZ3-1 |

| Worktable Structure | Flat Dual Worktable and Dual Rotating Axis Work Structure |

| Running Speed | 6000 drills/h |

| Suction drill bit quantity | 3 nozzles 1 glue tip |

| Drill disc fixation method | Movable spring jackscrew on the upper side of the platform |

| Spot drilling accuracy | ±0.02mm |

| Control system | industrial grade five-axis motion controller |

| Main operating system | SuperbMelt self-developed system |

| Drive system | High-end servo |

| Transmission method | high precision screw guide |

| Z*Y*Z/A/C effective stroke | 550*150*110mm/+150°-90°/360 degrees |

| Working power | AC220V/50Hz |

| Rated voltage | 2.5kw |

| Working air pressure | 80psi(0.4Mpa) |

| Equipment size | Length 780*Width 730*Height 1430mm |

| Equipment weight | about 450KG |

- High Efficiency: Completes both glue dispensing and stone setting at a speed of 8000-11000 pieces per hour, ensuring high production efficiency.

- Quick Switching: The machine allows for quick switching between glue dispensing and stone setting processes, ensuring a smooth production flow.

- Simple Operation: Only requires two simple steps (material replacement and start) for operation. Easy to handle, even for beginners.

- Smart Recognition: The intelligent recognition system automatically detects empty stone slots, avoiding unnecessary glue dispensing and ensuring precise production with automatic error correction.

- High Precision: Ensures high precision in both glue dispensing and stone setting, protecting both the product and stones, while maintaining accurate paths and stable output.

- Five-Axis Linkage: Equipped with a five-axis linkage worktable, it can rotate 360 degrees without restriction, supporting various complex designs including flat, 3D, large-angle, and large-arc structures.

- Multi-functionality: This machine simultaneously completes glue dispensing and stone setting, and can also be used solely for wax inlay. It is suitable for a wide range of jewelry, hardware, and other craft products.

Jewelry Manufacturing: The machine is widely used in the production of fine jewelry, where precision is key in the glue dispensing and stone setting processes for rings, necklaces, bracelets, and earrings.

Crafts and Artisanal Goods: It is also applicable for intricate crafts, such as hardware and decorative items, where small stones or embellishments need to be precisely placed and secured.

Hardware and Metalworking: Used for setting stones or applying glue in decorative hardware pieces, such as custom belt buckles, bag ornaments, or premium metal products.

Luxury Goods: The machine is suitable for high-end accessory production, including watches and other luxury items that require high-precision stone setting and glue application.

Why SuperbMelt Stone Dispensing Setting Machine

Any Question About SuperbMelt Stone Automatic Glue Dispensing and Setting Machine

Guide of SuperbMelt Stone Automatic Glue Dispensing/Setting Machine

SuperbMelt Latest Innovation: Glue Dispensing and Stone Setting Machine

SuperbMelt’s Latest Glue Dispensing and Stone Setting Machine combines advanced technology for efficient and precise jewelry production. This innovative machine offers dual-functionality, seamlessly integrating glue dispensing and stone setting in one operation. It boasts high-speed performance, capable of processing 6,000 stones per hour, with a five-axis workbench that supports 360-degree rotation for complex designs. The system also features intelligent detection for empty stones, ensuring smooth production with minimal errors, making it an essential tool for jewelry and hardware industries looking to enhance efficiency and product quality.

Difference between a Stone Dispensing Setting Machine and a Stone/Diamond Setting Machine primarily:

Process :

The jewelry production process involves setting the diamonds into a wax mold first. The diamonds are held in place by prongs surrounding each cavity. Once the stones are securely in position, the mold is removed, and the final product undergoes polishing to create the finished jewelry piece.

Stone Dispensing Setting Machine

Process:

This machine’s production process is entirely different from the wax setting method. First, the jewelry piece is fully crafted and polished. Afterward, glue is applied, and diamonds are set in place, with the adhesive holding the stones securely instead of using prongs.

Technology and Software of the SuperbMelt Stone Dispensing Setting Machine

Software System:

- User-friendly operating interface, easy to operate and navigate.

- Supports Chinese/English language switch to meet different user language requirements.

- Equipped with an in-house developed industrial-grade motion control system, which is feature-rich and enables precise monitoring of various process parameters.

Artificial Vision Motion Control Platform:

The software’s visual recognition positioning and stone hole processing can effectively reduce processing errors and achieve high-precision fixed-point drilling and dispensing.

Visual System:

Supports CCD programming, saving the cost of manual teaching time.

Automatic needle alignment system, effectively improving the positioning accuracy of the machine head.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited