Jewelry Investment Mixer

The Most Popular Vacuum Investment Powder Mixer for Casting on the Market

Jewelry investment mixer can mix casting powder and water into a uniform slurry, solidify to form a gypsum mold, and finally use it to cast jewelry. The key to the finish and fineness of jewelry in vacuum casting is the process of pouring the refractory into the flask.

SuperbMelt’s Jewelry Investment Mixer integrates vacuuming, powder mixing and powder injection, high automation and greatly increased efficiency. Compared with other complex processes of investment powder vacuuming machines, it is more simple and convenient, saving time and effort.

The mini powder mixer is compact and practical, the maximum capacity can reach 800g, and the size of the flask is 100x120mm. This equipment is more suitable for small and medium-sized jewelry manufacturing studios.

The vacuum vibrating powder mixer with a capacity of 15kg, which can accommodate five 4×10-inch flasks. The vacuum vibrating function can reduce air bubbles and water droplets in the powder, thus providing conditions for high-precision casting, suitable for medium and large jewelry processing and manufacturing plants.

Investment Mixer Parameters

| Model number | SPB-IPM2 | SPB-MIPM1 | |

| Photo |  View More Details

View More Details |

View More Details

View More Details |

|

| Power source | Three phase 380V, 50/60Hz | One phase 220 v,50/60 Hz | |

| Power | 500w | 350w | |

| Applicable | Mix investment powder | Mix investment powder | |

| Flask chamber size | φ350*H300 | / | |

| Mixer chamber size | φ300*H400 | / | |

| Max Capacity | 5 pcs of 4*10 inch flask | 1pcs 100 mm x 120 mm flask | |

| Powder weight | 15kg | 800g | |

| Dimension | 780*650*1500mm | 390*510*540mm | |

| Weight | 150kg | 18kg | |

| Mixing time setting | Available | Available | |

| Vacuum time setting | Available | Available | |

| Water auto feeding | Available | Available |

Complete Vacuum

The whole process is in a complete vacuum state, which reduces the bubbles and water droplets of the slurry, making the outline of the jewelry mold smoother and clearer, meeting the requirements of precision casting.

Short Working Time

While stirring the powder, the vacuum is drawn so that the whole process of stirring, powder injection and molding can be completed quickly in a vacuum environment.

Scale Cylinder

The clear scale ensures accurate measurement, accurately achieves the gouache ratio, and avoids loss.

Closed Work Environment

The whole process is closed to avoid environmental pollution and operator hazards from potentially harmful silica dust particles.

Vibration Function

The flask is equipped with a vibration function, which can adjust the strength. It makes the mixture more uniform and compact, and the wax mold is pressed more firmly, which can reduce the subsequent processing time and avoid the loss of metal.

Flexible Work

The mixing time and speed of water and powder can be adjusted according to product and production needs.

Large Capacity Powder Tank

With the max ability to mix :5 Pcs of 12.7* 25.4cm and one pc of 45*35cm.

Meet the needs of large jewelry manufacturers,Increasing production.

Easy to Operate

The control panel is clear and simple, with button operation and equipped with warning lights to ensure operator safety.

Equipment Design

The high-quality stainless steel makes the body more sturdy and waterproof, and it is equipped with wheels for easy movement according to the working environment.

2 years warranty

The warranty for our machine is one year longer than the warranty provided by other factories.

Strong service team

We will give response within 24 hours against your problem by our professional engineer.

Why SuperbMelt Jewelry Investment Mixer

Any Question About SuperbMelt Jewelry Investment Mixer

Guide of SuperbMelt Investment Mixer

Let’s dive right in:

The most important thing when choosing a investment mixer machine is to judge the output. Different models have different powder capacities and different flasks that can be placed at the same time.

15kg Jewelry Investment Mixer

The powder mixer can hold 15kg of powder, and the maximum capacity is 5 pcs 4*10 inch flasks. According to the customer’s flask size, it achieves mass production and suitable for medium and large jewelry processing factories, including making some gypsum molds for gold and silver rings, pendants, ornaments, etc. According to different product requirements, the corresponding vacuum and powder mixing time can be adjusted.

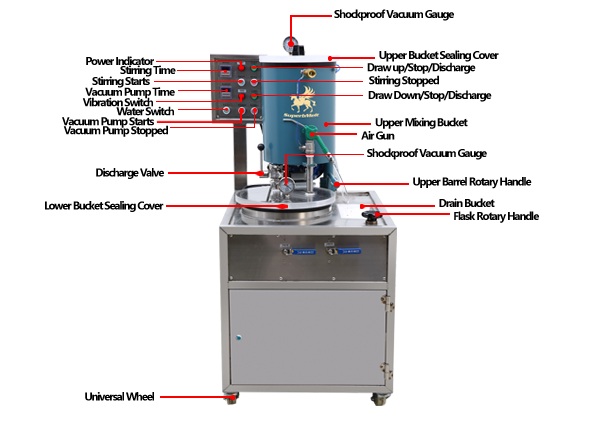

1.1 Machine composition

1.2 How to Use

Step 1: According to the ratio of water to powder, weigh the investment powder and measure the water.

Step 2: Check whether the powder gate of the mixing barrel is closed and whether the vacuum valve of the upper barrel is open.

Step 3: Use the rising bar to lift the upper bucket, move out the upper bucket, place the flasks that needs to be filled with powder in a circular shape on the down bucket, and restore the upper bucket.

Step 4: Open the upper bucket lid and pour the measured gouache in batches

Step 5: Turn on the mixer, set the time to 2-3min, and the vacuum time to 5-6min

Step 6: After the stirring is completed, turn off the agitator, align the flasks with the powder discharge gate, turn the gate, and after the slurry is injected in sequence, close the powder discharge gate, and open the down barrel to vacuumize.

Step 7: While filling the powder, pour clean water into the upper bucket and stir. After the powder filling is completed, discharge the sewage and further clean the upper bucket.

Mini Tabletop Jewelry Investment Mixer

Mini Jewelry powder mixer can only hold one flask at a time, the maximum size is 100mm*120mm, and the powder can hold up to 800g. It is very compact and does not take up space.

Therefore, it is more suitable for jewelry studios. For example, it is specially used as a mold for customized wedding rings. Its high-definition scale bar can make the gouache ratio more accurate, and it also works in a vacuum environment, which can achieve high-quality casting.

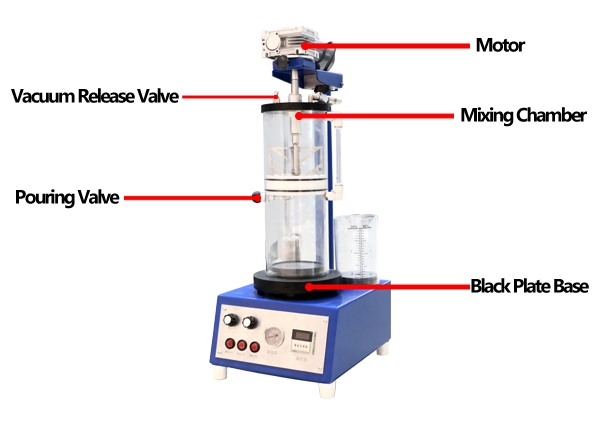

2.1 Machine composition

2.2 How to Use

Step 1: Weigh the required investment powder.

Step 2: Take out the transparent barrel cover, put the beaker into the powder injection position, and then restore the barrel cover.

Step 3: Turn on the vacuum pump, let the working environment reach a vacuum state and then turn it off.

Step 3: Pour the powder into the upper bucket, seal the lid, open the water valve, and adjust the water volume according to the scale.

Step 4: Press the stirring button, stir for 3-4 minutes, turn off the button when the stirring is complete.

Step 5: Open the powder injection valve, align the powder mouth to the beaker and pour it. After filling, press the vibration button to judge the vibration by hand.

Step 6: Clean the mixing tank in time after use.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited