Silver Bar Making Machine

1-2kg Gold and Silver Bar Casting Machine

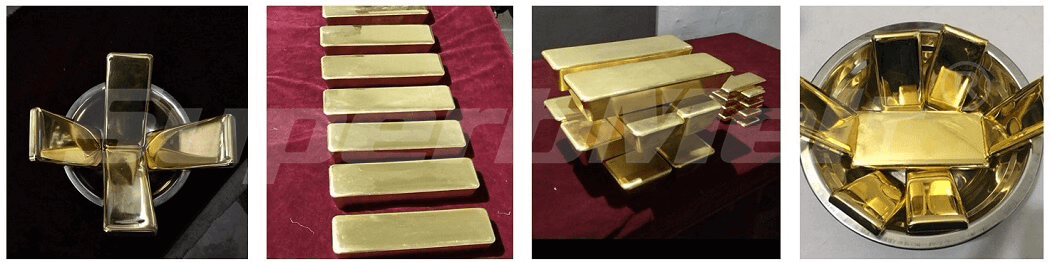

More Details of Silver Bar Making Machine

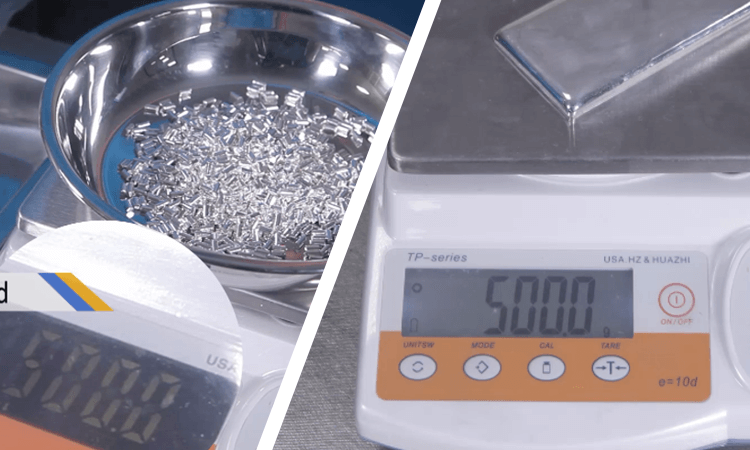

The silver bar making machine is designed to cast about 1kg to 2kg of ingots. The silver casting machine allows you to cast silver and gold ingots according to the LMBA standards.

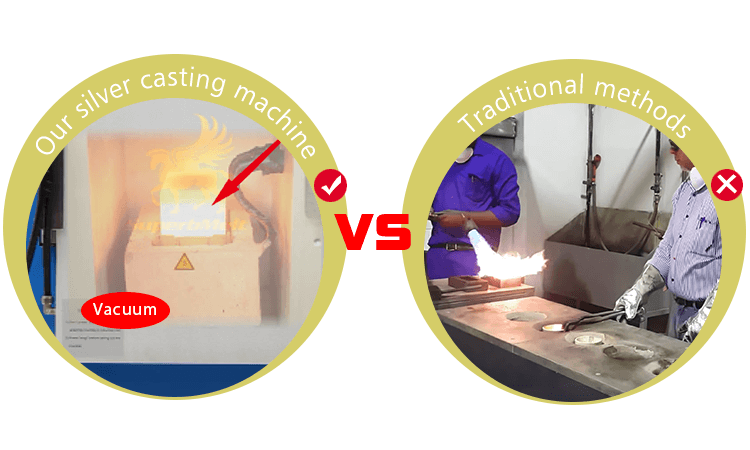

Superbmelt silver bar making machine provides a clean, accurate, non precious metal wastage and efficient way of casting ingots compared to traditional method of casting ingots. The pressurized inert vacuum gas of the silver casting machine prevents cast ingots from shrinkage, porosity and oxidation.

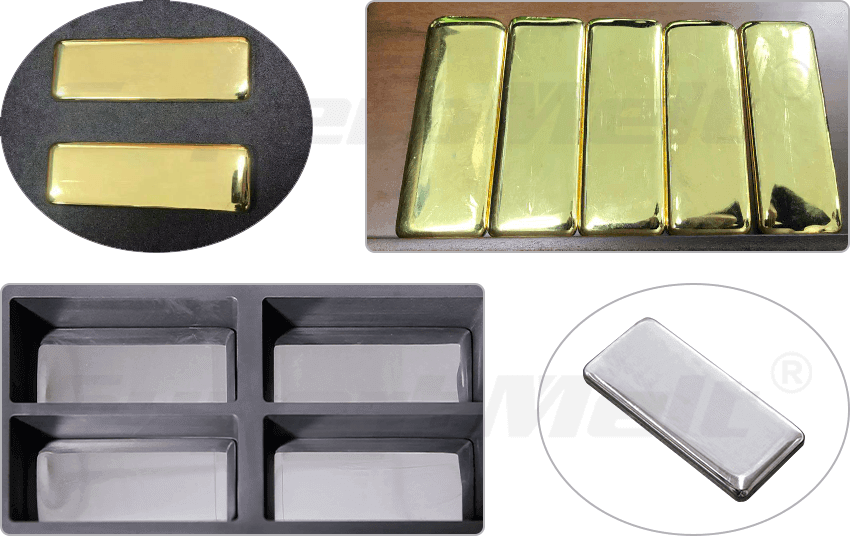

Ingots cast with Superbmelt silver bar making machines are always top quality with a mirror appearance. The silver casting machine is very affordable for your business, easy to use, install and maintain. The casting machine is very safe for both operator and the environment.

Get Price of Silver Bar Making Machine

Features of Silver Bar Making Machine

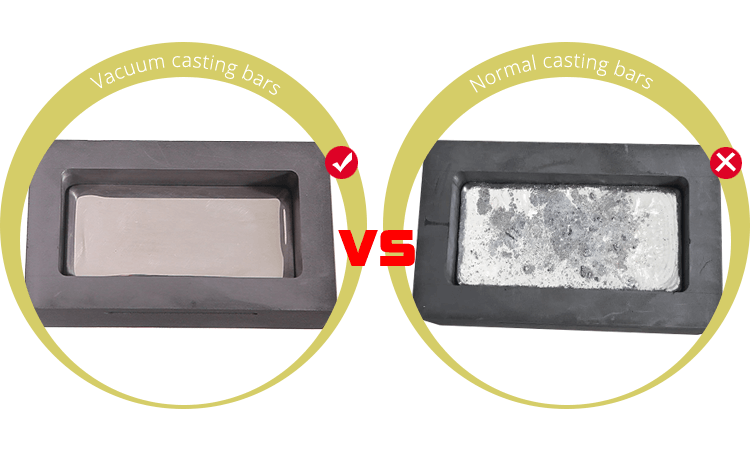

Without contact with air, the surface of gold bars are more smooth, no oxidation, no porosity.

The whole casting environment is closed, and no precious metal will be lost.

Comparing normal casting, vacuum casting bars are with flat and shiny surface and density.

Details of Silver Bar Making Machine

- With the silver bar making machine from Superbmelt, you can cast high quality ingots measuring 1kg to 2kg. Gold and silver casting with this machine is widely acceptable in the markets.

- The silver casting machine is suitable for banks, precious metal collectors, foundries, etc.

- The silver casting machine is very easy to use, users can switch between automatic modes and manual mode.

- The silver casting machine makes use of protective gas (nitrogen or argon), which protects ingots against porosity, shrinkage and oxidation.

- The total time needed for casting is 12 minutes, which helps you to save production time compared to when you cast ingots with other methods.

- The power required for melting is 15kw through induction heating. Induction heating helps to conserve energy, therefore, you spend less of power usage.

- All ingots cast with the silver casting machine are high quality with a glossy appearance.

- The omnidirectional warning system alerts users of issues such as irregular frequency or system overheating.

- The silver bar making machine is safe to use. Operators are not exposed to naked flame compared to traditional methods of silver bar making.

- With the aid of an industrial chiller, your machine heating temperature is in check, this allows you to cast ingots continuously without the casting machine breaking down or affecting the quality of cast ingots.

- The silver bar making machine is equipped with a green technology that makes the casting machine environmentally safe. No emission of toxic gases, smoke or noise.

- The silver casting machine provides a clean method of casting ingots, also, you don’t experience precious metal loss when you cast with a Superbmelt silver making machine.

| Model number | SPB-JD1 |

| Power source | Three phase 380V, 50/60Hz |

| Power | 15 kw |

| Applicable metal | Gold and silver |

| Casting time | About 12 mins |

| The Max capacity | 2kg gold bar or 1kg silver bar |

| Dimension | 1000*800*1350 mm |

| Weight | 205 kg |

| Protective gas | Nitrogen or argon |

| Vacuum pump | 63 m³/hour |

| Heating technology | Induction heating |

| Casting mode | Auto and manual mode switch |

Graphite mold for gold/Silver bar casting machine

Choosing a right casting mold for gold/silver bar casting will improve the efficiency and quality of castings and save the cost of lost parts

Any Question About SuperbMelt Silver Bar Making Machine

Superbmelt’s professional technical team and sales team are at your service

(7/24hours service)

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited