Silver Plate Continuous Casting Equipment

Gold & silver plate continuous casting equipment

More Details of Silver Plate Continuous Casting Equipment

The jewelry continuous casting machine is used to make metal rods, plates and bars of different shapes. Rod shapes that can be cast include rectangular, cylindrical, circular, and hexagon shapes. Metals such as gold, silver, copper, etc, are suitable for use in this machine.

The silver plate continuous casting equipment has the ability of rapidly chilling the cast rod to the point of solidification. The rapid chilling in the mold ensures a fine, uniform grain structure in the solidified metal with higher physical properties than other types of casting.

The jewelry continuous casting furnace is very easy to install, use and maintain, this is as a result of the PLC control panel.

The maximum melting temperature is 1600 degree celsius and you don’t need much power to achieve this.

Get Price of Silver Plate Continuous Casting Equipment

Features of Silver Plate Continuous Casting Equipment

Adopting gas protective melting, accurate temperature control, and auto stirring function make the finished product’s surface bright, with no air hole and oxidation.

Designed for high-density gold, K gold, silver and other enhanced precious metal plates, rods, rectangular rods, circular tubes, and other shapes of products.

It can heat up to a maximum temperature of 1600℃ . This is a temperature range in which most metals melts.

Details of Silver Plate Continuous Casting Equipment

- The silver plate continuous casting equipment has the ability to cast regular shapes and certain irregular shapes in long tabular form, which is difficult for other casting methods.

- Continuous cast materials are consistently dense and homogeneous in structure and therefore, well-suited for pressure application.

- Continuous castings have an inherent advantage in mechanical properties over other methods because of the chilling system and the excellent feeding of molten metal during solidification.

- The silver plate continuous casting equipment is both time saving and cost saving. The power required for melting is between 15kw and 25kw coupled with the maximum drawing speed of 40cm per minute, helps to save both cost and time for large scale production.

- The protective gases (nitrogen or argon) prevents oxidation, shrinkage and porosity of continuous castings.

- The heating system done by induction helps to save energy, such that all energy generated by the continuous casting machine is used within the machine. Hence, no heat escapes that can lead to a harsh working environment.

- The PID controller is able to detect temperature with an accuracy of ±2 degree celsius.

- Superbmelt silver plate continuous casting equipment has an electromagnetic stirring function that improves the quality of production.

- The melting temperature is 1600 degree celsius, this is capable of melting metals like gold, silver, copper, brass, bronze and their alloys.

- The operational panel automates the casting process, therefore it is easy to use. You don’t need many workers for your continuous casting line.

- The silver plate continuous casting equipment ensures uniformity in the production of metal objects. If you are producing 10 objects or more, you will have the same size, shape and composition.

- Superbmelt jewelry continuous casting machines have a long service life.

| Model number | SPB-LS4 | SPB-LS8 |

| Power source | Three phase 380V, 50/60Hz | Three phase 380V, 50/60Hz |

| Power | 15 kw | 25kw |

| Max Current | 15A | 26A |

| Applicable metal | Gold, Silver, Copper, Brass, Bronze, and their alloys | Gold, Silver, Copper, Brass, Bronze, and their alloys |

| The Max capacity | 24K Gold: 5.0 kg 18K Gold: 3.5 kg 925 Silver: 2.5 kg | 24K Gold: 8.0 kg 18K Gold: 6.0 kg 925 Silver: 4.0 kg |

| Melting time | 5 min | 8 min |

| Casting Application | Rod: φ4-φ20mm Tube: Min φ9*12mm Max φ52*60mm Bar: Min T5*W5mm Max T20*W70mm | Rod: φ4-φ20mm Tube: Min φ9*12mm Max φ52*60mm Bar: Min T5*W5mm Max T20*W70mm |

| Max temperature control R-type | 1600℃ | 1600℃ |

| Max temp control k-type | 1100℃ | 1100℃ |

| Max drawing speed | 40 cm/minute | 40 cm/minute |

| Dimension | 1120×840×1560 mm | 1120×840×1560 mm |

| Weight | 195 kg | 205 kg |

| Protective gas | Nitrogen or argon | Nitrogen or argon |

| Heating system | Induction heating | Induction heating |

| Control of temperature | By PID | By PID |

| Accuracy of temperature | ±2 degrees Celsius | ±2 degrees Celsius |

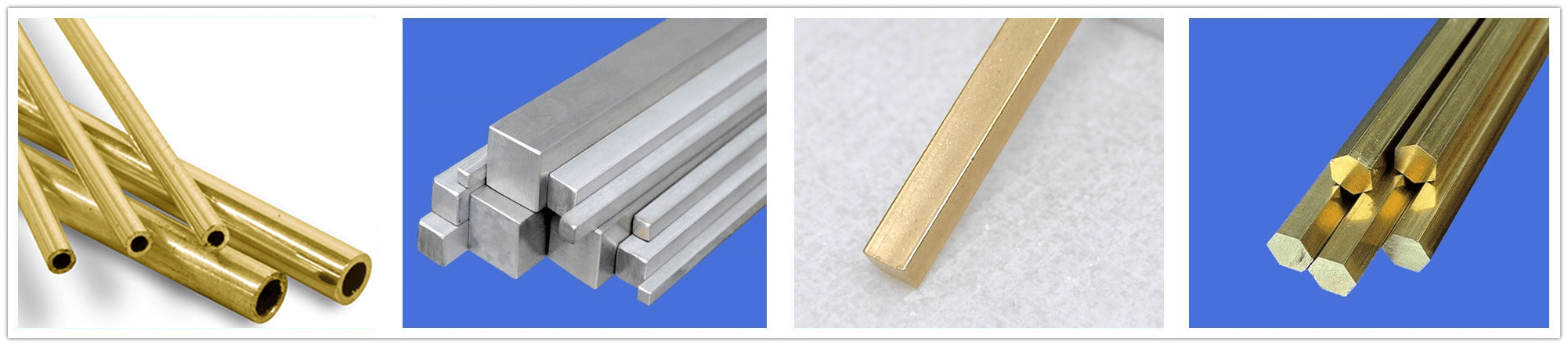

Gold tube

Square silver bar

Square gold bar

Hexagon gold bar

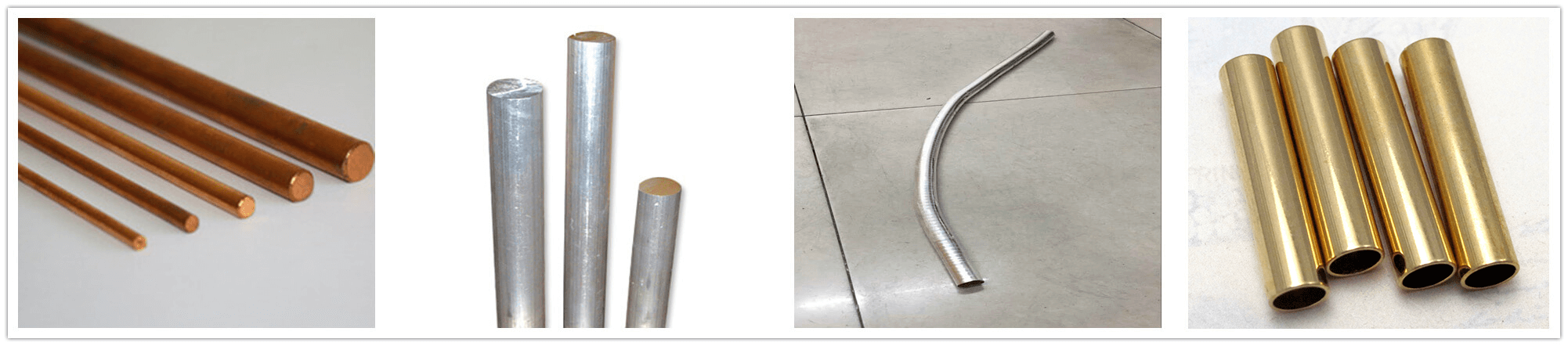

Copper bar

Silver bar

Silver tube

Gold tube

Any Question About SuperbMelt Silver Plate Continuous Casting Equipment

Superbmelt’s professional technical team and sales team are at your service

(7/24hours service)

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited