Silver Tube Continuous Casting Machine

Copper Silver gold tube continuous casting machine

More Details of Silver Tube Continuous Casting Machine

The jewelry continuous casting machine is designed to cast metal rods, tubes, plates, and other shapes. The silver tube continuous casting machine is able to cast metals such as high density gold, K-gold, silver, copper, lead, zinc etc.

Within the silver tube continuous casting machine, molten metal enters the mold, solidifies and comes out from the side as continuous stripes. It is widely used in jewelry making industries, aerospace industry, steel production industry, etc.

Since the introduction of the jewelry continuous casting machine in the market reduces waste while improving yield, quality, productivity and cost efficiency. The gas protective melting reduces the chance of impurities and the electromagnetic system ensures even consistency of metal before casting into rods.

Get Price of Silver Tube Continuous Casting Machine

Features of Silver Tube Continuous Casting Machine

Adopting gas protective melting, accurate temperature control, and auto stirring function make the finished product’s surface bright, with no air hole and oxidation.

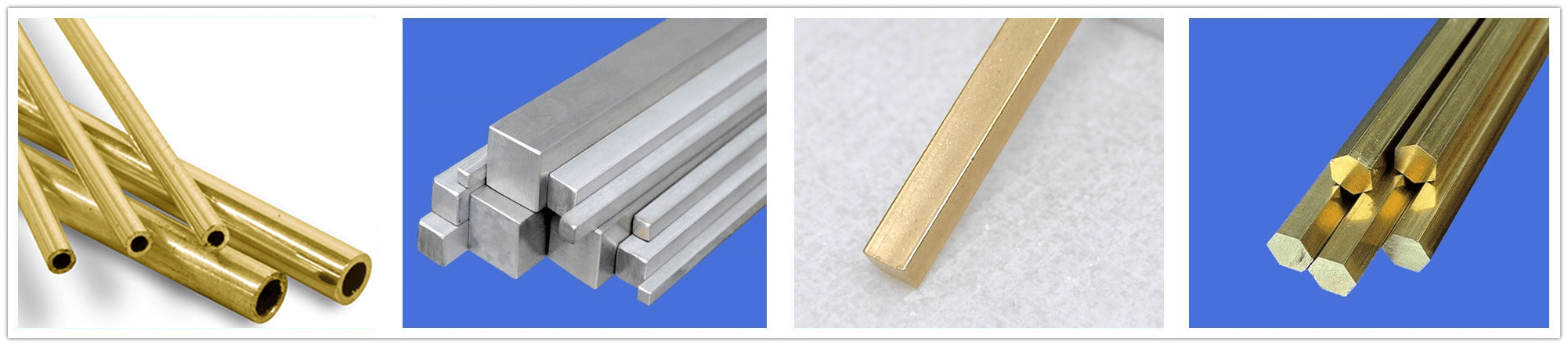

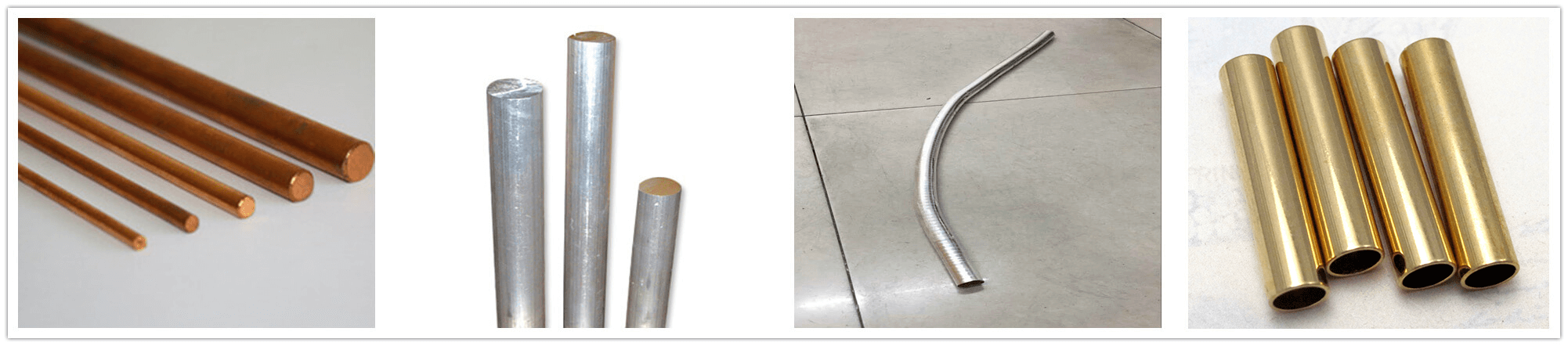

Designed for high-density gold, K gold, silver and other enhanced precious metal plates, rods, rectangular rods, circular tubes, and other shapes of products.

It can heat up to a maximum temperature of 1600℃ . This is a temperature range in which most metals melts.

Details of Silver Tube Continuous Casting Machine

- With the silver tube continuous casting machine, you can cast various shapes depending on the product end use. You can cast gold tube, hexagon gold bar, square gold bar, square silver bar, copper bar, silver tube, etc.

- The continuous casting machine is the perfect method for manufacturing semi-finished products of long sizes. It also allows the production of large batches within a short time. Melting and casting takes approximately 8 minutes.

- When compared to casting molds, continuous casting is more economic as regards to the use of energy. You need between only 15kw to 25kw of power to get your silver tube continuous casting machine working.

- All operations within the jewelry continuous casting machine is automated and controlled. There is also the possibility to adapt to production flexibility and rapidly changing market requirements.

- The induction heating system present within the jewelry continuous casting machine helps to conserve energy, prevent heat loss during melting and prevent contamination of metal.

- Superbmelt’s silver tube continuous casting machine is able to cast 40cm of tubes and rods in one minute. Therefore contributing to a fast production process.

- The PID controller helps to detect accuracy of temperature of ±2 degree celsius. The PID controller also automates the whole melting and casting process. Hence, it saves you the cost of hiring many workers.

- The maximum melting temperature is 1600 degree celsius. This makes it possible to cast metals whose temperatures are less than 1600 degree celsius into tubes and rods.

- The rod or tube after casting is passed through the cooling device. This can then proceed for packaging or the next step of production as soon as possible. No need for delay in your production line.

| Model number | SPB-LS4 | SPB-LS8 |

| Power source | Three phase 380V, 50/60Hz | Three phase 380V, 50/60Hz |

| Power | 15 kw | 25kw |

| Max Current | 15A | 26A |

| Applicable metal | Gold, Silver, Copper, Brass, Bronze, and their alloys | Gold, Silver, Copper, Brass, Bronze, and their alloys |

| The Max capacity | 24K Gold: 5.0 kg 18K Gold: 3.5 kg 925 Silver: 2.5 kg | 24K Gold: 8.0 kg 18K Gold: 6.0 kg 925 Silver: 4.0 kg |

| Melting time | 5 min | 8 min |

| Casting Application | Rod: φ4-φ20mm Tube: Min φ9*12mm Max φ52*60mm Bar: Min T5*W5mm Max T20*W70mm | Rod: φ4-φ20mm Tube: Min φ9*12mm Max φ52*60mm Bar: Min T5*W5mm Max T20*W70mm |

| Max temperature control R-type | 1600℃ | 1600℃ |

| Max temp control k-type | 1100℃ | 1100℃ |

| Max drawing speed | 40 cm/minute | 40 cm/minute |

| Dimension | 1120×840×1560 mm | 1120×840×1560 mm |

| Weight | 195 kg | 205 kg |

| Protective gas | Nitrogen or argon | Nitrogen or argon |

| Heating system | Induction heating | Induction heating |

| Control of temperature | By PID | By PID |

| Accuracy of temperature | ±2 degrees Celsius | ±2 degrees Celsius |

Gold tube

Square silver bar

Square gold bar

Hexagon gold bar

Copper bar

Silver bar

Silver tube

Gold tube

Any Question About SuperbMelt Silver Tube Continuous Casting Machine

Superbmelt’s professional technical team and sales team are at your service

(7/24hours service)

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited