Gold Granulation

Vacuum granulating machine for gold, silver grain casting

More Details of Gold Granulation

The vacuum gold granulation is a machine designed to cast precious metals into granules or grains. The raw material is placed in the melting chamber, the furnace is then sealed. The vacuum gold granulation makes use of induction heating in a protective environment for melting and granulating.

The gold granulation process begins once the precious metal reaches its melting point within two minutes. After granulation is complete, the grains are poured into the water tank passing through a multi-hollowed crucible that serves as a flow breaker.

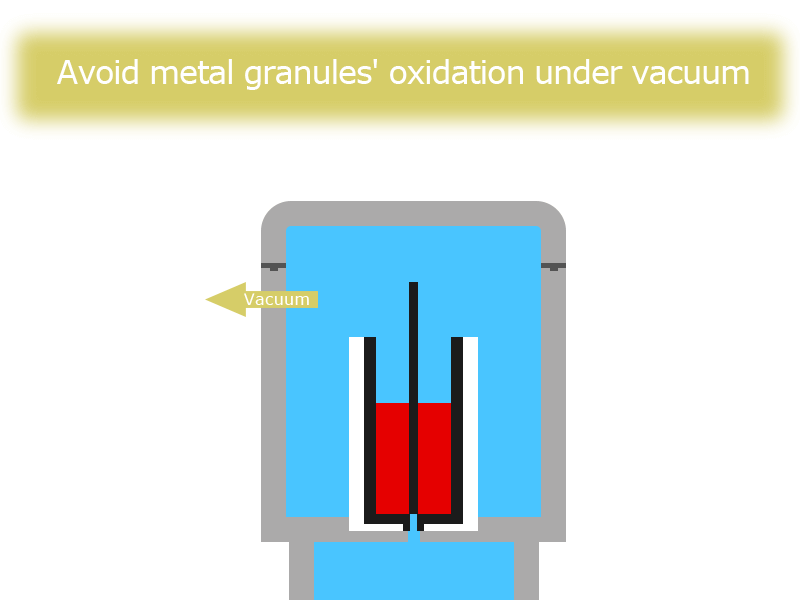

The precious metal granules are well formed into spherical shapes without oxidation loss under vacuum. With the use of a vacuum granulator, granules are smooth, shiny and they have high density. The vacuum gold granulation is a fast and safe process of gold granulation.

Get Price of Gold Granulation

Features of Gold Granulation

It adopts fully vacuum and inert gas melting and granulating, the machine can automatically stir in melting and the finished products have no oxidization, producing equal particles, good color and good sphere.

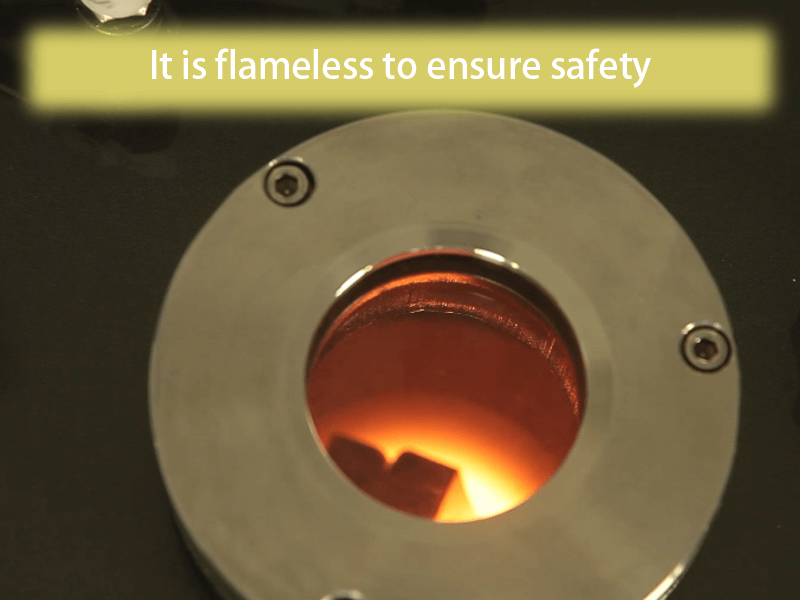

The whole process is carried out in airtight gold, and there is no flame in the whole process to ensure safety. Heating coil with low-voltage design, insulted heating, safe, and table.

Details of Gold Granulation

- The PLC control system and observation window allows you to properly monitor the melting and gold granulation process.

- The vacuum gold granulation requires about 15kw to 25kw of power. This implies that there is no requirement for heavy power usage before the vacuum granulator can work.

- Melting and granulation is done under a protective environment with the use of protective gas such as argon.

- The maximum melting temperature of the vacuum gold granulation is 1600 degree celsius. Melting is complete within 5 to 6 minutes, therefore, the entire process of gold granulation is less than 10 minutes. This however contributes to a fast production process.

- The PID controller present in the vacuum gold granulation is responsible for automatic regulation of the melting temperature, speed of melting, pressure, flow, etc.

- Superbmelt vacuum gold granulation is capable of casting the following metals into granules: gold, K-gold, silver, copper, brass, bronze and their alloys.

- The casting system is done under vacuum, this means that all heat generated for melting is used only within the melting chamber, that is no escape of heat that can lead to energy wastage. The vacuum system also prevents contamination of the granules.

- All granules cast with the vacuum granulator are smooth, evenly shaped, good colour and no oxidation.

- The vacuum granulator equipment is equipped with a water tank that prevents the granules from sticking together during the granulation process, so that each granule can stand on its own.

- The induction system allows for homogenization of molten metal due to the stirring effect of the magnetic field which works while melting is on within the crucible.

- The water in the tank alongside the powerful chiller keeps the temperature and the granules under control in order to obtain quality granules.

| Model number | SPB-VS5 | SPB-VS10 | SPB-VS20 |

| Power source | Three phase 380V, 50/60Hz | Three phase 380V, 50/60Hz | Three phase 380V, 50/60Hz |

| Power | 15 kw | 15 kw | 25kw |

| Casting system | Vacuum casting system | Vacuum casting system | Vacuum casting system |

| Applicable metal | Gold, K-Gold, Silver, Copper, Brass, Bronze, and their alloys | Gold, K-Gold, Silver, Copper, Brass, Bronze, and their alloys | Gold, K-Gold, Silver, Copper, Brass, Bronze, and their alloys |

| Melting time | 5-6 min | 5-6 min | 5-6 min |

| The Max capacity | 24K Gold: 5.0 kg 925 Silver: 2.5 kg | 24K Gold: 10.0 kg 925 Silver: 5.0 kg | 24K Gold: 20.0 kg 925 Silver: 10.0 kg |

| Max heating temperature | 1600℃ | 1600℃ | 1600℃ |

| Max. temp control k-type | 1100℃ | 1100℃ | 1100℃ |

| Casting chamber size | D275*H1100mm | D330*H840mm | D385*H1000mm |

| Dimension | 730*935*1600mm | 800*1020*1700mm | 850*1050*1800mm |

| Weight | 175KG | 235KG | 265KG |

| Protective gas | Argon | Argon | Argon |

| Vacuum pump (Optional) | 63 m³/hour | 63 m³/hour | 63 m³/hour |

| Control of temperature | by PID | by PID | by PID |

| Accuracy of temperature | ±2 degrees Celsius | ±2 degrees Celsius | ±2 degrees Celsius |

| Vacuum filter | Y | Y | Y |

| Vacuum leakage detector | Y | Y | Y |

| Casting chamber lift | Y | Y | Y |

Application of vacuum granulator

Any Question About SuperbMelt Gold Granulation

Superbmelt’s professional technical team and sales team are at your service

(7/24hours service)

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited