Water Metal Atomizer

Professional Manufacturer in China

- Mass production of gold, silver, platinum, palladium, copper, zinc, aluminum and other precious and non-precious metal powders.

- The water pressure can be adjusted to make the mesh sizes controllable.

- Capacity ranges 10-100kg metal rapid powder making.

- 80% of metal powder can reach less than 50 mesh.

- Reduced metal dissolving speed in aqua regia refining to increase production efficiency.

SuperbMelt uses a combination of melting furnace and water metal atomizer to achieve the pulverization of most metals and alloys. Especially some refractory metals with high melting point and high reactivity characteristics, including Au, Ag, Pd, Pt, Co, Cu, Ni, Fe, Zn, etc.

In the traditional metal milling process, limited by physical factors, the powder cannot be changed according to the cleanliness and fineness required by customers.

Our metal powder atomizer can custom the particle size of the powder within 50-200 mesh according to the processing technology required by customers.

Under the use of ultra-high pressure water system, the metal liquid can be broken into fine metal droplets, and a large number of sub-spherical and irregular particles can be formed after rapid cooling of water, and under the protection of inert gas, the finished powder can be made very meticulous.

Our metal powder atomizer can be customized according to the customer’s industrial application, use environment, output requirements, etc.

We have basic equipment for metals such as gold, silver and copper, and the temperature can reach 1500. In addition, we also have equipment with a temperature of 2200, which is specially designed for stainless steel, platinum, palladium, rhodium and other metals. The melting range is 10-100kg, and the power is 15-100kw.

Machine Multiple Protection

Our metal powder making equipment has multiple protections, equipped with short circuit protection, over current protection and over voltage protection.

Temperature protection and separation of water and electricity can be achieved. If the machine is faulty, the staff will be alerted by an alarm.This greatly protects the safety of the operator. Correct use by the operator can also give the machine a longer lifespan.

Fully Automatic Operation

Our metal powder making machine equipped with PLC system and can realize fully automatic operation.

The machine structure is simple, has a clear screen interface, and the operation can be completed with one key. No professional training is required. We will provide online and offline training guidance, which can greatly save training costs.

High Productivity

The configuration of the high-pressure water system greatly improves the milling efficiency, and 25kg of metal powder can be produced one hour.

The number of meshes can also be adjusted according to process requirements.

Our water atomization pulverizing technology can not only greatly shorten the production time, but also greatly reduce the production cost.

Wide Application

Our water metal atomizer is suitable for many metal processing industries, such as refining and purification plants, solder industry, new material processing industry, precious metal processing industry.

The applicable metal range is also very wide, platinum, palladium, gold, silver, copper, etc.We have provided this technology for major university laboratories, new material processing plants, jewelry manufacturers and so on.

The application industry of metal powder is very wide, such as the military industry, equipment manufacturing, instrumentation, metal industry, electronic appliances and other fields of spare parts and related raw materials, accessories, sintering equipment, powder preparation equipment.

The configuration of the melting furnace can be customized, from 10kg to 100kg. Whether it is a small precious metal refinery processing plant or a large metal material processing plant, we can provide the most suitable solution.

Specific product use: automobiles, textile machinery, industrial sewing machines, power tools, hardware tools, electrical engineering machinery and other powder metallurgy parts.

Classification: porous materials, anti-friction materials, friction materials, structural parts, tool and mold materials, electromagnetic materials and high-temperature materials.

| Model | SPB-VPM4 | SPB-VPM10 | SPB-VPM30 | SPB-VPM50 | SPB-VPM100 |

| Voltage | 380V | ||||

| Power | 45kw | 25kw | 50kw | 70kw | 100kw |

| Max Temperature | 1600-2600℃ | ||||

| Melting Time | 15-20Min | 20-25Min | |||

| Max Capacity | 4kg(Pt) | 10kg(Au) | 30kg(Au) | 50kg(Au) | 100kg(Au) |

| Applicable Metals | Au、Ag、Cu、Pt、Pd、Rh | ||||

| Milling specifications | 50-200Mesh | ||||

| Cooling Method | Water Cooling | ||||

| Milling Time | 20Min | 35Min | 60Min | ||

| Dimensions | 1500*1300*2100mm | ||||

| Weight | 800kg | 850kg | 900kg | ||

Water Atomization Pulverizing Method

Water can be recycled, more environmentally friendly and cost saving

Fast Melting Speed

The melting speed is very fast, saving time and cost and improving production efficiency

Stainless Steel Powder Box

Adopt stainless steel powder collecting box to avoid powder adhesion and effectively prevent material loss

Why SuperbMelt Water Metal Atomizer

2 years warranty

The warranty for our machine is one year longer than the warranty provided by other factories.

ISO CE SGS approved

Professional certification bodies certify that the machines are of high quality.

Strong service team

We will give response within 24 hours against your problem by our professional engineer.

Any Question About SuperbMelt Water Metal Atomizer

Guide of SuperbMelt Water Metal Atomizer

Features and Advantages

Nowadays, the wide application of various metal powder manufacturing technologies has made great progress in powder metallurgy technology. Due to the relatively stable production process, few uncontrollable factors and low cost of water atomization powder technology, it has been widely used in various industries.

Low Production Cost

Water atomization pulverizing technology realizes a simple and short production process based on the traditional pulverizing process, so the production cost is lower, and it is very suitable for low-end products that need to control costs.

Wide Production Range

The configuration of the melting furnace can be customized, from 10kg to 100kg. Whether it is a small precious metal refinery processing plant or a large metal material processing plant, we can provide the most suitable solution.

Strong Antioxidant Effect

Our equipment is equipped with an inert gas protection system. When making powder, an inert gas that can protect the atmosphere is introduced into the atomizing tower, thereby reducing the oxidation of metals and alloys and making the oxygen content of the finished powder lower.

Reduce Losses and Contamination Levels

Atomizers, separators, collection chambers and other components are designed with stainless steel, which will avoid powder adsorption, so cleaning will be easier, thereby reducing the loss of metal powder and avoiding the risk of metal mixing and contamination.

Environmentally Friendly

The products obtained by using water atomization technology are of high quality and do not need to consume chemical reagents.

At the same time, the water can be recycled, so the environmental protection level is very high, and environmental friendliness and no pollution are realized.

How to Use SuperbMelt Water Metal Atomizer

Metal Melting

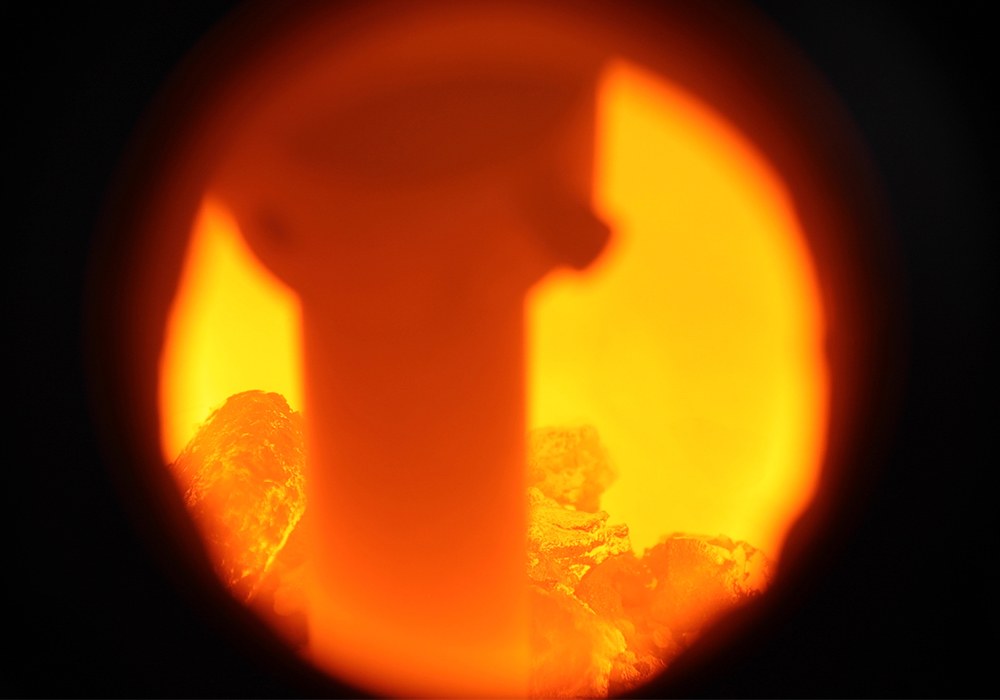

- Click the open button on the screen to put the metal into the melting furnace then close the hatch and lock the oven door.

- After setting the parameters through the PLC system, it can be smelted.

- During the smelting process, an electromagnetic stirring system is configured to make the solution more uniform.

- When the molten metal reaches a certain temperature, it will enter the atomizer through the nozzle of the crucible.

Melt Atomization

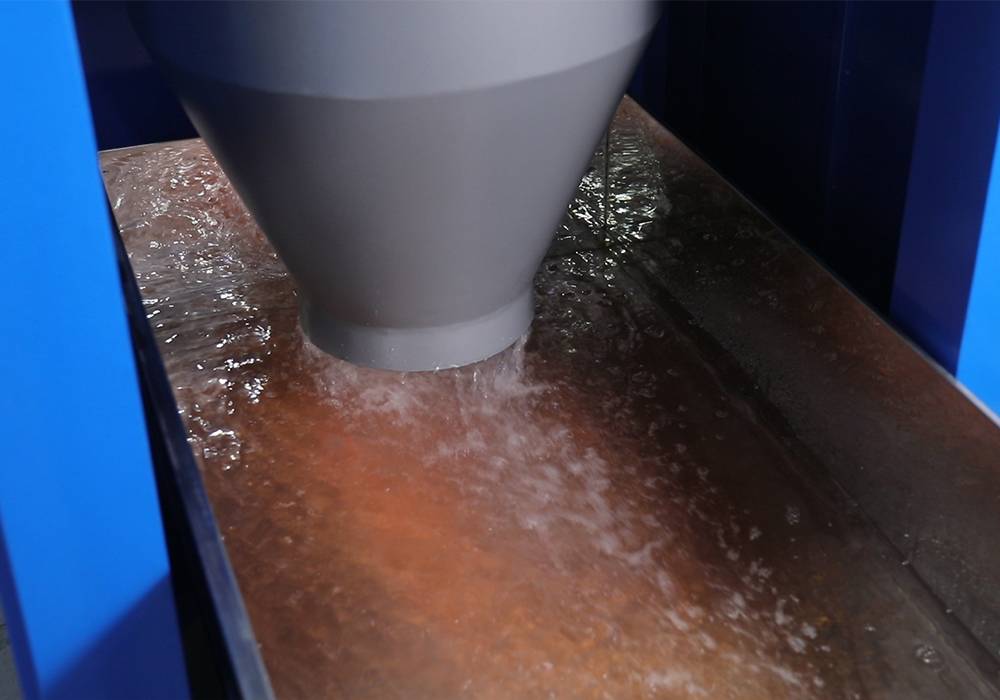

- After the molten liquid arrives in the atomization chamber, it is broken into fine droplets under the action of the high-pressure water system.

- Then fall into the cooling liquid of the equipment, and the liquid solidifies into metal powder.

- When the powder falls into the powder collection box, keep it for a while, and filter it after precipitation.

What is the Composition of SuperbMelt Water Metal Atomizer

Our water metal Atomizer require the cooperation of high-end machine components to achieve such high-efficiency and quality finished products. Such as smelting system, granulation mold, atomization system, high water pressure system, powder collecting box, water recovery system, control system, etc.

1. Melting System

Equipped with multifunctional melting furnace for a Metal melting unit, used with a suitable crucible.

2. Granulation Die

The metal is melted and turned into granulation through this part.

3. Atomization System

It provides high water pressure for atomizing nozzles.

4. Powder Collection Box

Stainless steel powder and grain recovery device with large space.

5. Water Recovery System

This unit recovers and filtration of process water.

6. Control System

Operation through touch-screen PLC control system.

FAQ of Metal Atomizer

What is Water Atomizing Process

Water Metal Atomizer also known as metal powder making machine with ultra-high pressure water atomization. The traditional pulverizing process is to pour the molten metal liquid into water to burst it into fine metal particles, but its efficiency is low and the quality of the finished product is not high.

The water atomization process enables continuous refining of metal powders under an environment with a maximum water pressure of 150mpa. The high pressure can be around 50-150mpa, and the fine metal powder can be obtained by high-pressure water jet and collision with the molten metal.

SuperbMelt’s ultra-high pressure water atomization method is simple, not only is the technology easy to control, but also has a high level of machine automation, resulting in high quality and low cost finished products.

Water atomization powder milling is a rapidly developing new process in powder metallurgy industry.

Water Metal Atomizer VS Gas Metal Atomizer in Produce Metal Powder

Atomization is the process of pulverizing metal solution into powder under the action of external force.

The use of high-speed airflow is gas atomization; the use of high-pressure water flow is called water atomization.

Different in Powder Shapes

The powders formed by water atomization and gas atomization are very different in shape. The water atomized powder presents an irregular shape, while the gas atomized powder presents a spherical shape.

The bulk density and fluidity of metal powders are affected by the shape, so water atomized and gas atomized powders are suitable for different application scenarios, and users can make reasonable choices according to their own needs.

Different in Cost of Production

Gas atomization is higher than water atomization, because gas atomization will generate some atomizing medium costs

The water atomization medium mainly consumes the electric energy when running the water pump. Therefore, gas atomized powder is generally more expensive than water atomized powder.

FAQ Guide of SuperbMelt Water Metal Atomizer

1. What Metal Powders Can be Made By the Water Metal Atomizer?

Gold, Silver, Copper, Iron, Platinum, Palladium, Rhodium

2. How to Choose the Power of The Machine?

Our equipment has 15kw-100kw, which can be selected according to the corresponding metal melting amount below:

15kw:10kg Au 4kg Pt 5kg Ag

35kw:30kg Au 10kg Pt 15kg Ag

70kw:50kg Au 15kg Pt 25kg Ag

100kw:100kg Au 50kg Ag

If other metals are involved, please contact us.

3. Can the Metal Powder Making Machine be Customized?

If you need to make gold and silver powder, only need to make a hole in the bottom of the crucible mold, while platinum, palladium and rhodium need to replace the melting device.

4. Can the Particle Size of The Powder be Adjusted?

The particle size of the powder can be adjusted by adjusting the water pressure, and the adjustable range is 50-200 mesh.

5. What Kind of Furnace is Used in The Melting Device of The Equipment?

The medium frequency induction furnace is adopted, and the melting capacity is in the range of 10-100kg, which can be selected according to the needs.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited