3D Automatic Wax Setting Machine

Professional jewelry manufacturing equipment supplier in China

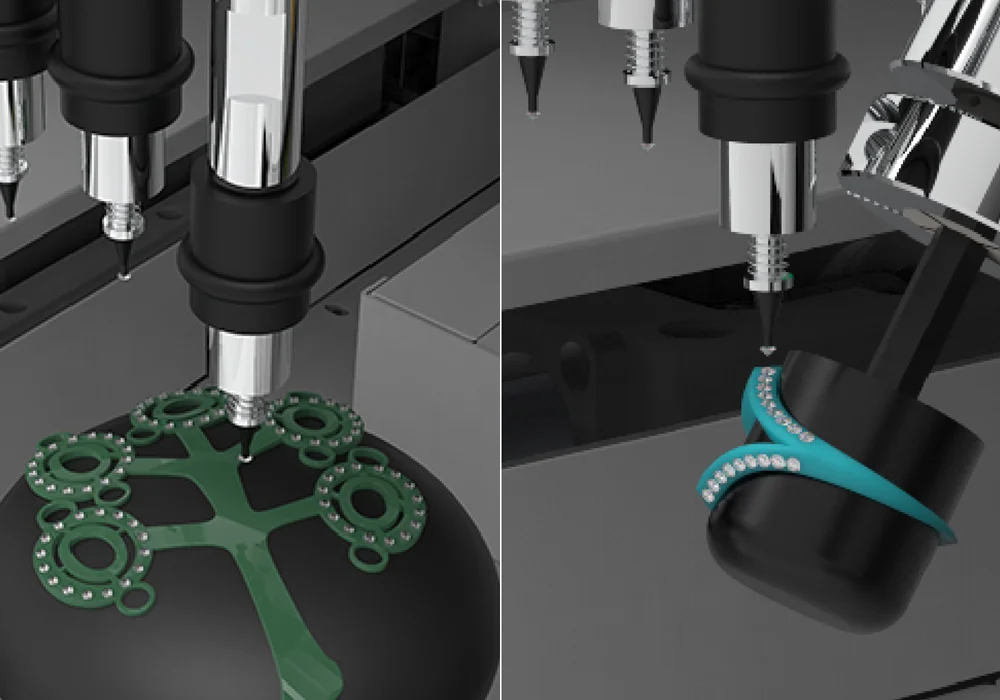

SuperbMelt mini wax setting machine can automatically set diamonds on jewelry wax models, and is used for post-production of gold, silver, copper and other diamond jewelry, such as rings, bracelets, earrings, pendants, etc.

Wax setting machine is suitable for large and medium-sized jewelry processing plants and manufacturing plants. The workmanship is fast, while restoring the effect of manual craftsmanship, the color and size of the inlaid diamonds can be customized. Under the operation of the 5-axis device, more complex and diverse diamond setting styles can be realized.

Automatic jewelry stone setting machine is very intelligent and adopts PLC control system to operate, which is more simple and convenient. Intelligent identification technology avoids wrong drilling and missed drilling, ensures the quality of finished products and improves production efficiency.

| Equipment nam | Mini Automatic Diamond Setting Machine |

| Equipment Model | SPB-3DZ500 |

| Workbench structure | Five-axis linkage workbench |

| Spot drilling speed | 9000-12000 drills / hour |

| Number of suction drill head | 3 suction nozzles |

| Fixing method of drill head | Embedded |

| Spot drilling accuracy | ±0.02mm |

| Control system | industrial five-axis motion controller |

| Main operating system | Self-research system of SuperbMelt Technology |

| Drive system | High-end servo |

| Transmission method | high precision screw guide |

| Z*Y*Z/A/C effective travel | 300*250*120mm/150 degrees-90 degrees/360 degrees |

| Working power | AC220V/50Hz |

| Rated voltage | 1.3kw |

| Working air pressure | 80psi(0.4Mpa) |

| Equipment size | length 780 * width 730 * height 1400mm |

| Equipment weight | about 350KG |

High Speed

The machine runs at a very high speed and can reach 9000-12000 pieces per hour. One machine is equivalent to the production capacity of 8 experienced employees. Mass production can be easily realized, which is very suitable for large-scale jewelry processing and manufacturers.

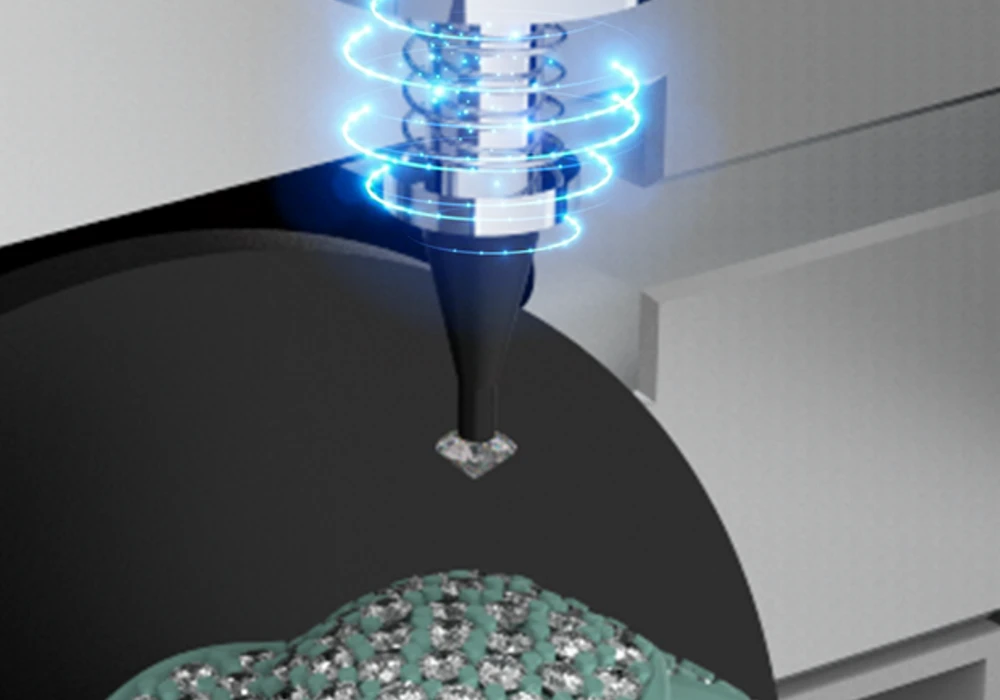

100% Restore Artificial

Flexible diamond settings, imitating the manual inlay process, adding a buffer device, the inlay strength is 100% artificial, and more efficient and accurate.

5 Axis Linkage

5 axes work at the same time, can achieve 540-degree rotation, and inlay complex and diverse 3D, curved and flat wax models. One machine can solve most wax mold inlay problems, and the cost performance is higher.

Multi-color&size

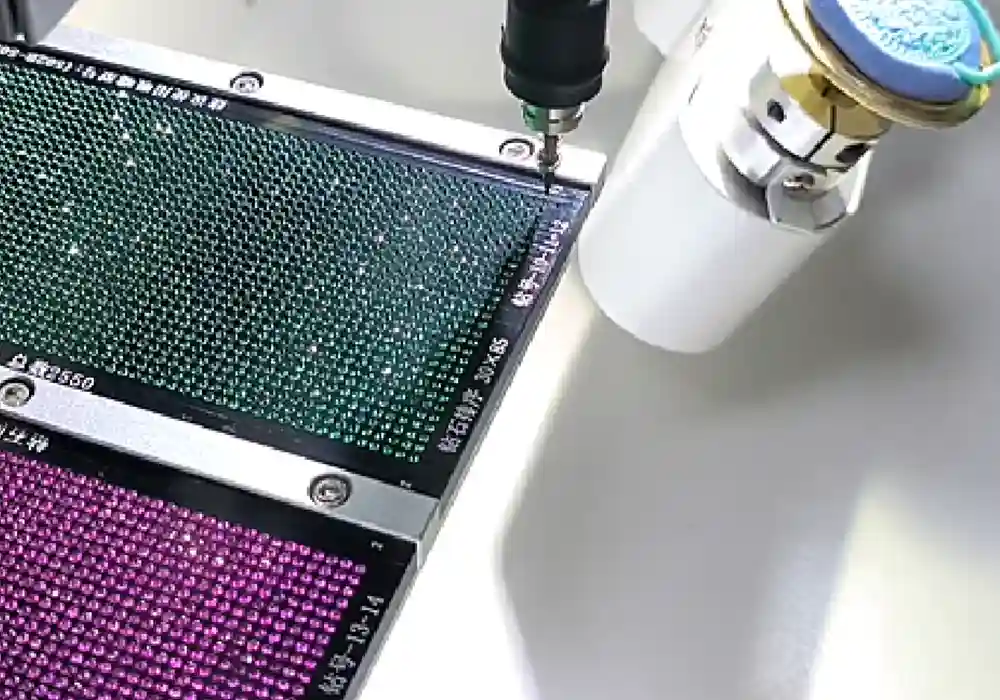

It can achieve monochrome or multi-color mosaic, up to 4 colors. The size of diamonds can be between 0.8-3.0mm, which can realize the diversification of a wax model, without the need for separate inlays, which saves more time.

Intelligent Identification System

The machine adopts intelligent recognition technology. When the suction nozzle detects that the diamond is misplaced or there is no blank, it will skip to the next diamond, which can ensure the quality of the wax model and avoid the occurrence of missing and wrong diamonds.

PLC Operation

It adopts plc touch screen panel control, and automatic control can be easily realized after setting parameters. It does not require workers to have professional certificates, and only needs simple training to complete.

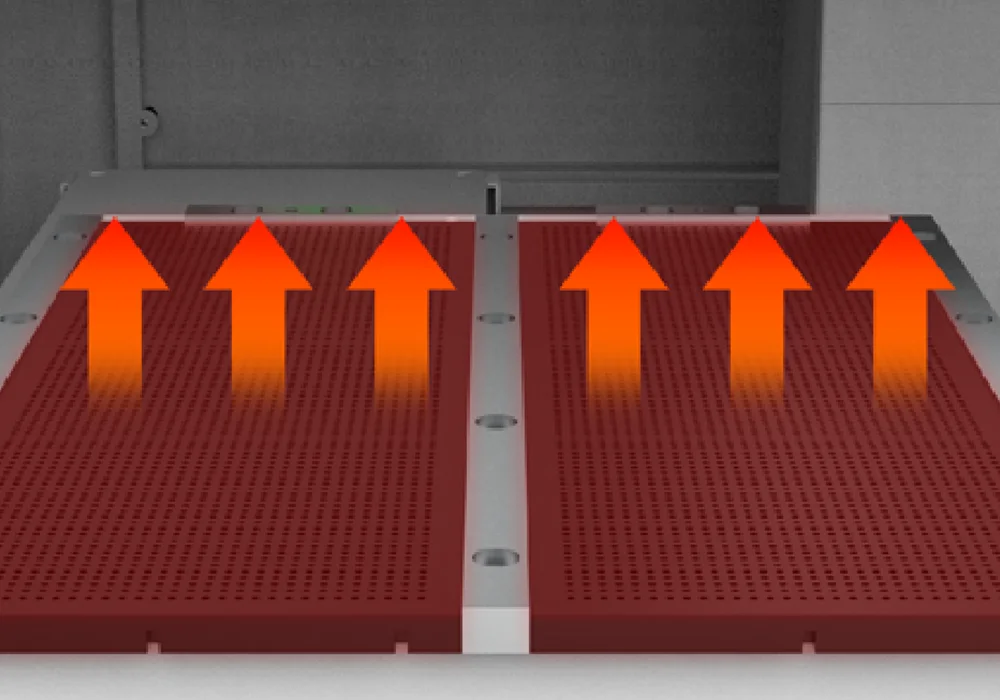

Tray Heating

The diamond tray has a heating function, which can be heated while inlaid, and can be better fused when placed in the wax mold to prevent the diamonds from falling.

Jewelry wax stone setting machine is a tool used in the jewelry making industry for setting stones or gems into wax molds, which are then used to create metal castings. The machine is designed to create precise and uniform holes in the wax that correspond to the size and shape of the stones, allowing the stones to be easily and securely set into the mold.

SuperbMelt mini wax setting machine is primarily used in the production of high-end jewelry pieces, such as engagement rings, wedding bands, and other fine jewelry items that require precision stone setting. The machine is particularly useful for setting small or delicate stones, as it ensures that each stone is set in the exact position and angle required for maximum visual impact and durability.

Overall, automatic wax stone setting machine is an essential tool for jewelry makers looking to create high-quality, precise, and visually stunning jewelry pieces that require precise stone setting.

Multi-color

Can achieve monochrome or multi-color mosaic, up to 4 colors.

Manual Reduction

Imitate manual strength, 100% replica artificial effect, more refined and perfect.

Intelligent Identification System

The suction nozzle can automatically identify diamonds, which can prevent wrong drilling and missing drilling.

Tray Heating

The diamond tray has a heating function, which can be inlaid more firmly.

5 Axis Linkage

5-axis work at the same time, easy to achieve flat, curved surface, 3D model with diamonds.

High Speed

One machine is equivalent to 8 workers, and can inlay up to 12,000 pieces per hour

Why SuperbMelt 3D Automatic Wax Setting Machine

Any Question About SuperbMelt 3D Automatic Wax Setting Machine

FAQ Guide of SuperbMelt 3D Automatic Wax Setting Machine

- 1. What Shapes of Diamonds does Wax Setting Machine Fit?

- 2. What Is the Capacity of The Automatic Stone Setting Machine?

- 3. What Sizes and Materials of Diamonds are Suitable?

- 4. Can Diamonds of Multiple Sizes and Colors be Set at Once?

- 5. How much Time does it Take to Set Up a Program?

- 6. Can Programming be Reused?

- 7. How to Program?

- 8. What are The Consumables that Need to be Prepared Regularly?

- 9. What Size of the Wax Models are Suitable for The Machine?

1. What Shapes of Diamonds does Wax Setting Machine Fit?

It is most suitable for round diamonds, for other shapes of diamonds, you can consult our sales to send detailed designs, we will try to customize for you.

2. What Is the Capacity of The Automatic Stone Setting Machine?

It can achieve 9000-12000pcs per hour, and the use of one machine can reach the output of 8 workers.

3. What Sizes and Materials of Diamonds are Suitable?

The machine is suitable for diamond sizes of 0.8-3.0mm, and can accept a variety of materials, such as rhinestones, glass drills, artificial stones, plastic drills, etc.

4. Can Diamonds of Multiple Sizes and Colors be Set at Once?

One machine can accept 4 sizes and colors of diamond inlays. After programming, it can be completed at the same time without separate operations.

5. How much Time does it Take to Set Up a Program?

According to the complexity of the style, the minimum programming time is 10 minutes, and the longest will not exceed 2 hours.

6. Can Programming be Reused?

The set programming can be saved, and you can directly click the saved programming to start working without changing the wax model. If you change the wax pattern of different styles, you need to re-align the holes and program.

7. How to Program?

The mini wax setting machine can only be programmed manually. For the first time, it is necessary to manually set the path of the suction nozzle. After confirming that it is correct, mass production can begin.

8. What are The Consumables that Need to be Prepared Regularly?

Plastic mold and clay mold, this one is used to fix the wax mold on the workbench;

The suction nozzle can be used repeatedly, and it needs to be re-customized when it is replaced with a new size;

Diamond trays, match the corresponding trays according to the color and size.

9. What Size of the Wax Models are Suitable for The Machine?

The size of the workbench is 80*80*40mm, if your wax model size is within this range, you can use it.

Guide of SuperbMelt 3D Automatic Jewelry Wax Setting Machine

How to Use the Wax Setting Machine?

Preparation

Step 1: Make Film

- Use soft glue to pinch out the desired shape and wait for it to solidify (use hot water to speed up)

- Spread the cement on the cured rubber mold, and fix the wax model to be set with diamonds on the cement

Step 2: Sieve Drilling

- Connected Screen Drilling Rig

- Turn on the lights and install the diamond tray

- After pouring diamonds, press the adsorption button

- Sweep the adjacent diamonds into the tray with a brush, and then use a sponge to gently smooth the diamonds in the tray

- Finally sweep the excess diamonds back to the collection area

Wax Setting

Step 1: Connect and Adjust the Equipment

- Connecting Power to the Air Compressor

- Adjust the pressure to 0.6mpa and 0.4point

- Turn on the main switch of the equipment, turn on the light and connect the operation keyboard

- After opening the tray storage area and adjusting the temperature, place the diamond tray carefully

Step 2: Manual Programming

- After installing the corresponding suction nozzle size, install the wax model tray on the workbench and lock it

- Use the keyboard to manually mosaic all the vacancies

- After the machine has recorded all the paths, the wrong position can be changed by the positioning and replacement buttons

- Finally save the complete and accurate programming

Step 3: Adjust Wax Setting Parameters

- Adjust air pressure for each nozzle connection

- Adjust the speed to 10%. At this time, the speed is slower and you can check whether the position is accurate again.

- Waiting until the first sample is done and checking for errors then can speed it up

Comparison between Wax Setting Machine and Manual Diamond Setting

Wax Setting Machine

Wax setting machines are highly automated and are designed to carry out the task of setting stones on jewelry pieces in a highly efficient and accurate manner.

They can be programmed to set stones in a specific pattern or design, and can set multiple stones at once.

The process is highly controlled, ensuring that the stones are set evenly and securely.

Manual Setting

Manual setting involves the use of hand tools to set stones on jewelry pieces. It is a highly skilled process that requires a great deal of experience and expertise. Manual setting is a more traditional method that is still used by many artisans today.

But manual diamonds setting requires a highly skilled operator, so the Hiring costs are higher, it is more suitable for small custom jewelry studio.

Manual setting is time-consuming and labor-intensive. Stones may not be set as evenly or securely as with a wax setting machine and greater potential for mistakes and errors.

Accessories of Jewelry Wax Setting Machine

The important accessories of the jewelry wax setting machine mainly include diamond tray, plastic clay, pinchable silicone, suction nozzle, diamond wiper sponge, filter, keyboard, and some hardware tools. Suction nozzles and trays can be customized according to customer needs. For example, when you have many diamond sizes and colors, you can additionally customize different suction nozzles and reasonable distribution trays. It is more flexible and can solve most jewelry diamond inlay products.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited